22

90-10185R30

GB

goh93

1

3

5

2

4

oh

MAINTENANCE

oho55

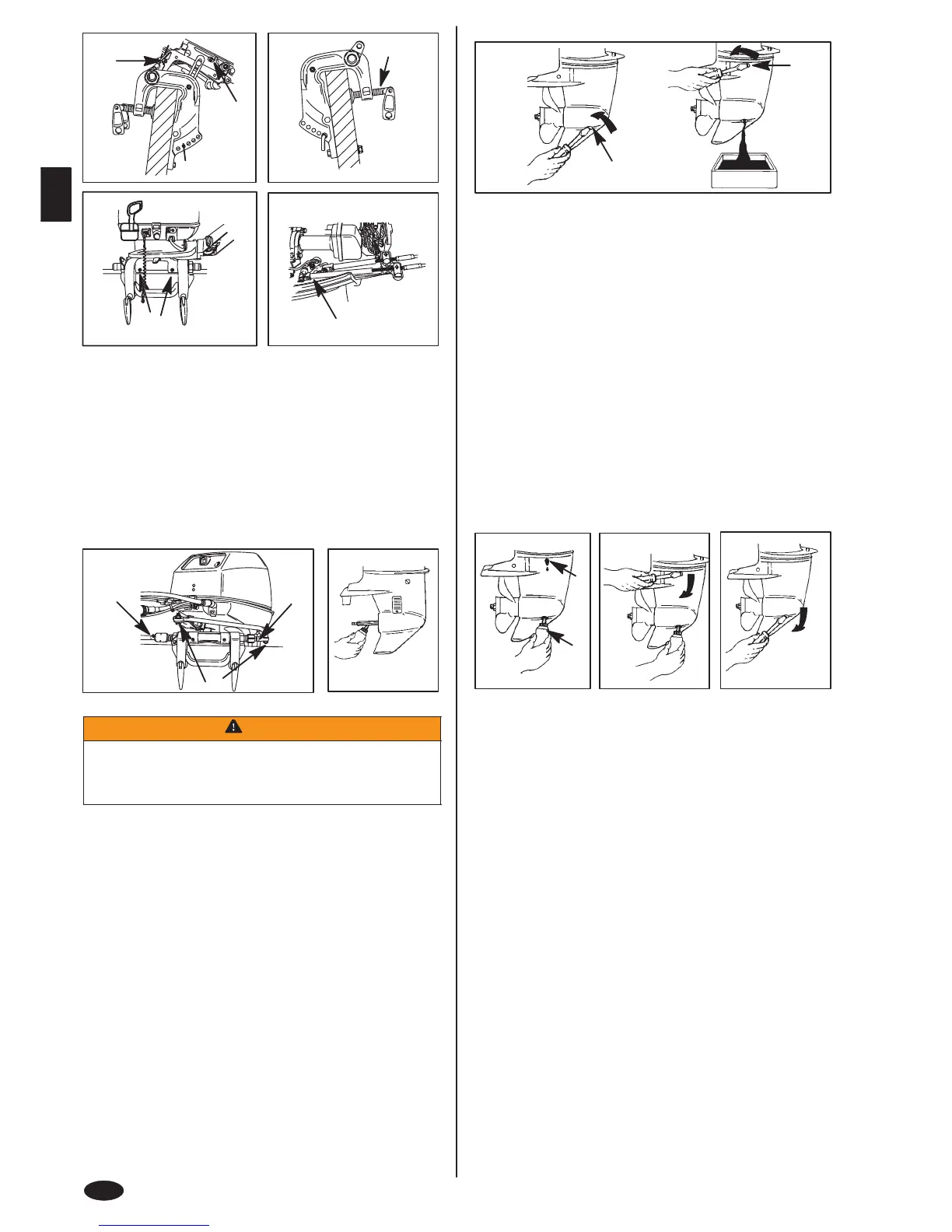

LUBRICATION POINTS

Lubricate Points 1 thru 6 with Quicksilver or Mercury Precision Lubricants

2-4-C Marine Lubricant with Teflon or Special Lubricant 101.

1 Steering Friction Adjustment Shaft (Tiller Handle Models) - Lubricate fitting.

2 Swivel Bracket - Lubricate fitting.

3 Transom Clamp Screws - Lubricate threads.

4 Tilt Tube - Lubricate fittings.

5 Lubricate the throttle and shaft cables, moving components and pivot

locations.

goh62

8

6-a

7

6-b

oho56

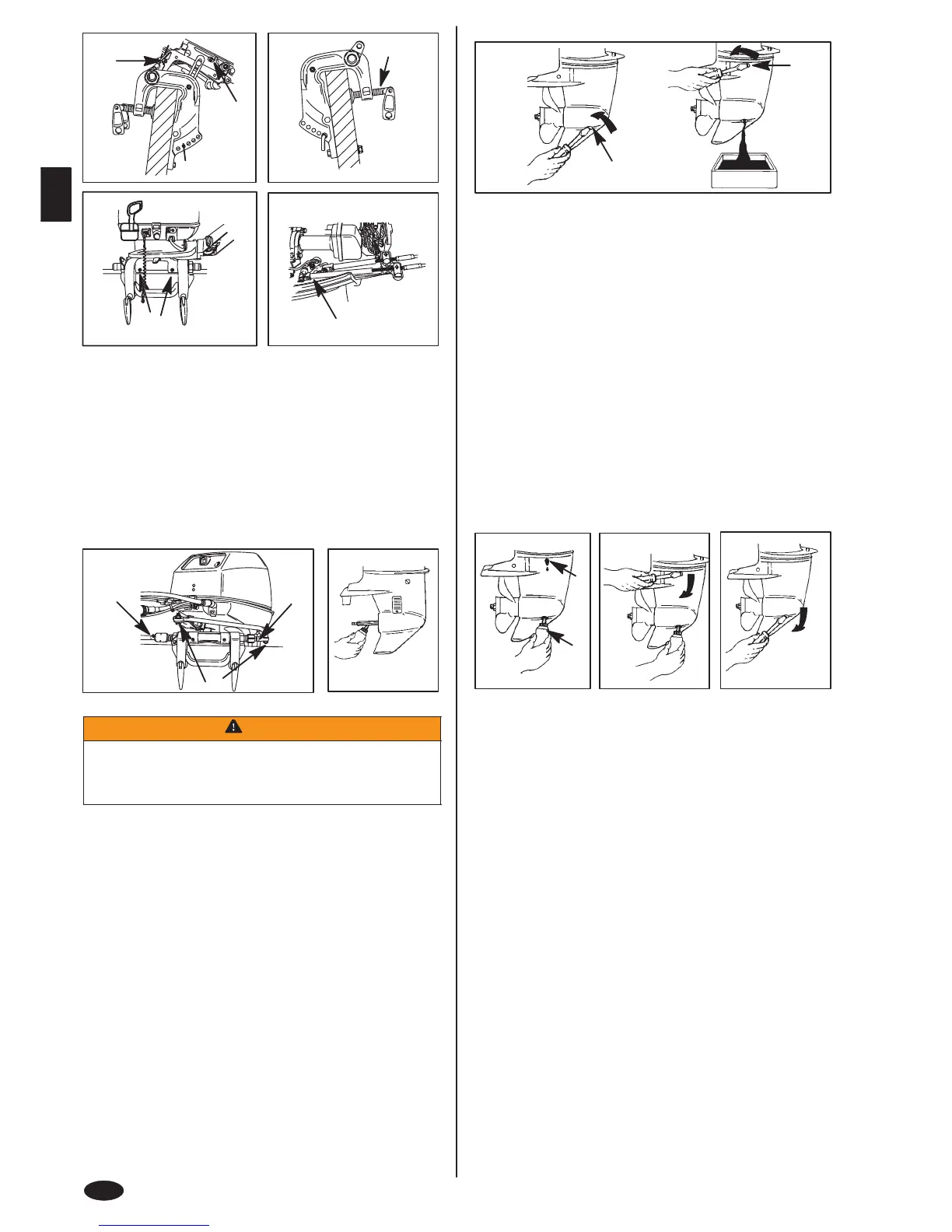

LUBRICATION POINTS (CONTINUED)

WARNING

The end of the steering cable must be fully retracted into the outboard tilt

tube before adding lubricant. Adding lubricant to steering cable when ful-

ly extended could cause steering cable to become hydraulically locked.

An hydraulically locked steering cable will cause loss of steering control,

possibly resulting in serious injury or death.

6 Steering Cable Grease Fitting (If Equipped) - Rotate steering wheel to fully

retract the steering cable end (a) into the outboard tilt tube. Lubricate through

fitting (b).

Lubricate points 7 With Light Weight Oil

7 Steering Link Rod Pivot Points - Lubricate points.

Lubricate Point 8 with Quicksilver Quicksilver or Mercury Precision

Lubricants Anti-Corrosion Grease or 2-4-C Marine Lubricant with Teflon.

8 Propeller Shaft - Refer to Propeller Replacement for removal and installation

of the propeller. Coat the entire propeller shaft with lubricant to prevent the

propeller hub from corroding to the shaft.

goh208

1-3

a

b

ohq2

GEAR CASE LUBRICATION

When adding or changing gear case lubricant, visually check for the presence of

water in the lubricant. If water is present, it may have settled to the bottom and will

drain out prior to the lubricant, or it may be mixed with the lubricant, giving it a milky

colored appearance. If water is noticed, have the gear case checked by your

dealer. Water in the lubricant may result in premature bearing failure or, in freezing

temperatures, will turn to ice and damage the gear case.

Whenever you remove the fill/drain plug, examine the magnetic end for metal

particles. A small amount of metal filings or fine metal particles indicates normal

gear wear. An excessive amount of metal filings or larger particles (chips) may

indicate abnormal gear wear and should be checked by an authorized dealer.

Draining Gear Case

1 Place outboard in a vertical operating position.

2 Place drain pan below outboard.

3 Remove fill/drain plug (a) and vent plug (b) and drain lubricant.

ohv10

Gear Case Lubricant Capacity

Standard model gear case: Approximately 6.8 fl. oz. (200 ml).

Bigfoot model gear case: Approximately 8.8 fl. oz. (260ml).

goh83

4

1-3

5

a

b

ohv3

GEAR CASE LUBRICATION (CONTINUED)

Checking Lubricant Level and Refilling Gear case

1 Place outboard in a vertical operating position.

2 Remove vent plug from vent hole (a).

3 Place lubricant tube (b) into the fill hole and add lubricant until it appears at the

vent hole (a).

4 Stop adding lubricant. Install the vent plug and sealing washer before removing

the lubricant tube.

5 Remove lubricant tube and reinstall cleaned fill/drain plug and sealing washer.

ohr1

SUBMERGED OUTBOARD

A submerged outboard will require service within a few hours by an authorized

dealer once the outboard is recovered from the water. This immediate attention by

a servicing dealer is necessary once the engine is exposed to the atmosphere to

minimize internal corrosion damage to the engine.

Loading...

Loading...