ENGINE INSTALLATION

128 eng

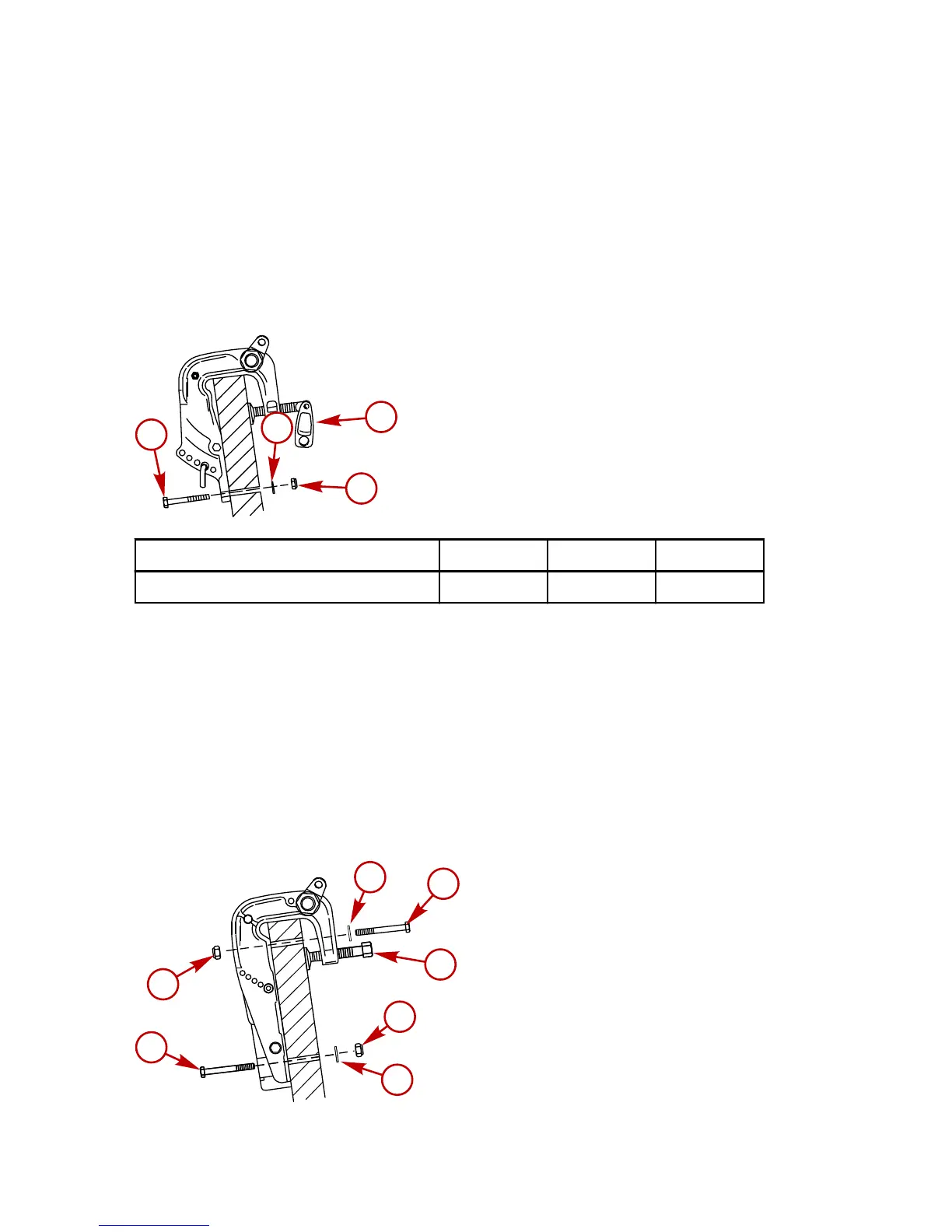

3. Non‑power tilt models ‑ To prevent a loss of the outboard,

secure the outboard to the transom with the two transom

bracket clamp screws and two mounting bolts. Drill two

7.9 mm (5/16 in.) holes through the transom bracket

mounting holes. Fasten with two bolts, flat washers, and

locknuts. Use a marine waterproofing sealer in the holes

and around the bolts to make the installation watertight.

Tighten the bolts to the specified torque.

a - Bolts (2)

b - Washer (2)

c - Locknut (2)

d - Transom bracket clamp

screws (2)

Description Nm lb. in. lb. ft.

Transom bracket mounting bolts 13.5 10

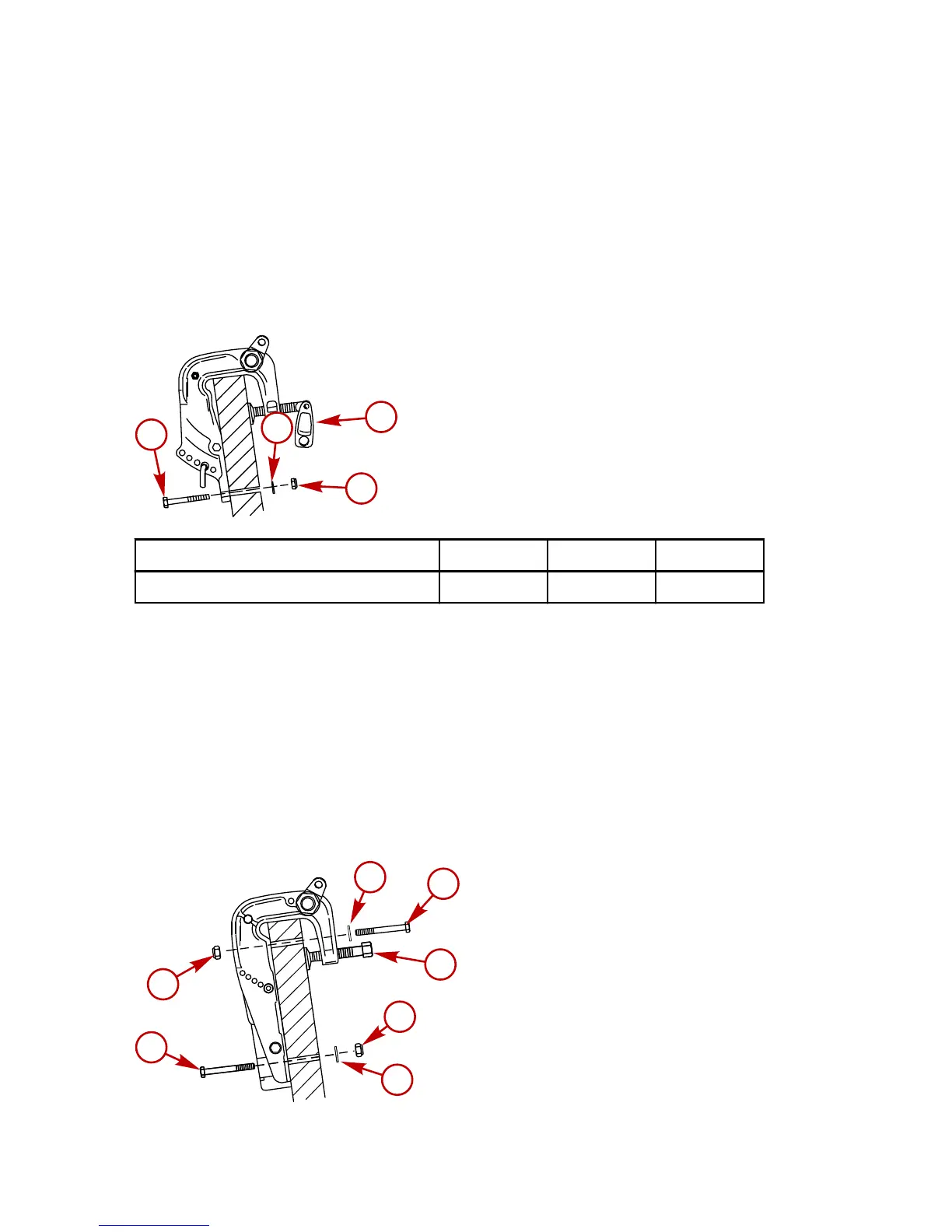

4. Power tilt models ‑ To prevent a loss of the outboard, secure

the outboard to the transom with the two transom bracket

clamp screws and four mounting bolts. Drill two 7.9 mm

(5/16 in.) holes through the upper set of transom bracket

mounting holes and drill two holes through the lower set of

mounting holes or mounting slots. Fasten with four bolts, flat

washers, and locknuts. Use a marine waterproofing sealer in

the holes and around the bolts to make the installation

watertight. Tighten the bolts to the specified torque.

a - Locknut (4)

b - Washer (4)

c - Bolts (4)

d - Transom bracket clamp

screws (2)

Loading...

Loading...