DIRECT FUEL INJECTION

Page 3B-58

90-888438 JUNE 2002

REASSEMBLY

1. Lubricate end cap O-ring and O-ring contact area in compressor body with two cycle

oil.

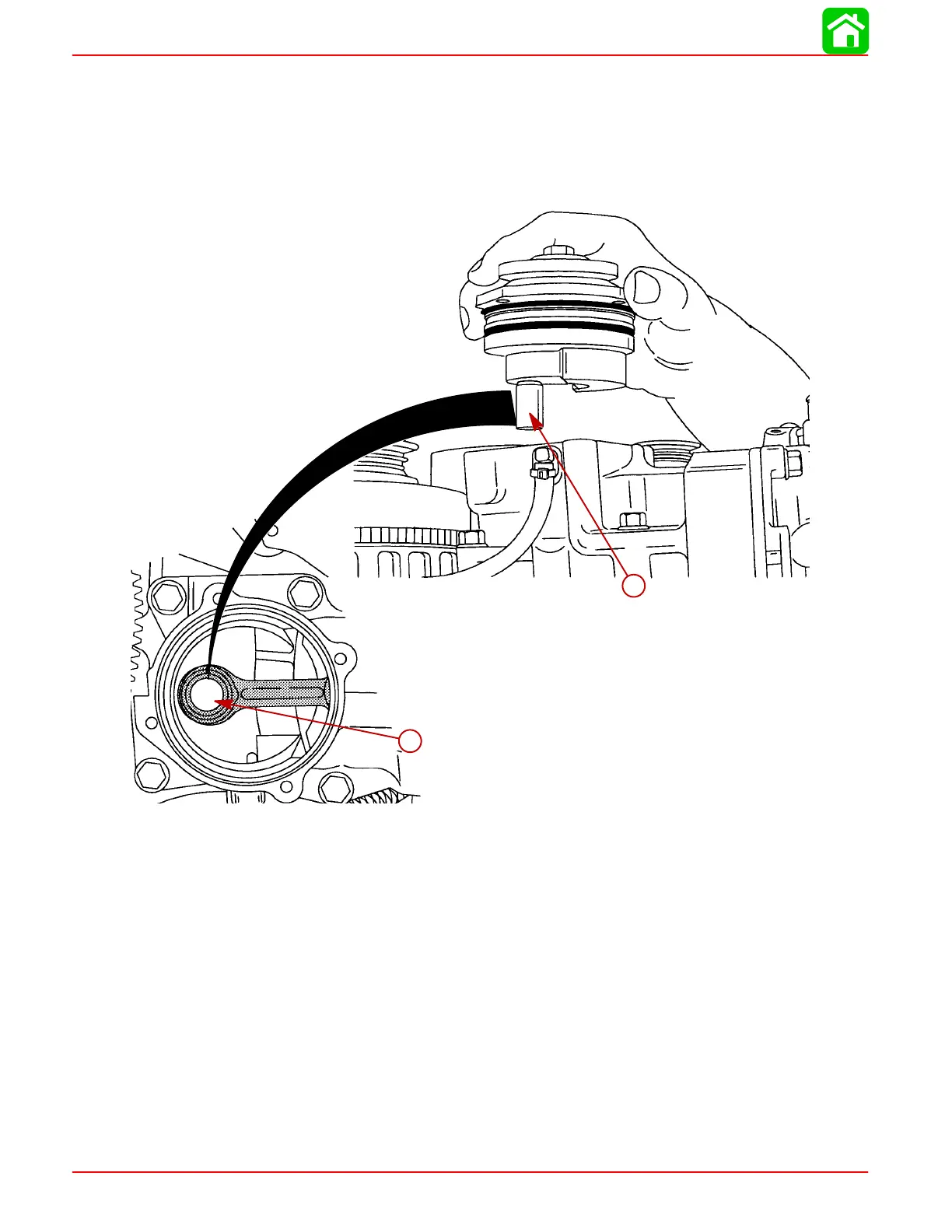

2. Slide the new end cap assembly into the compressor body, keeping the connecting

rod journal lined up with the open end of the connecting rod, until the crankshaft just

enters the open end of the connecting rod.

a

b

a-Connecting rod open end

b-Crankshaft connecting rod Journal

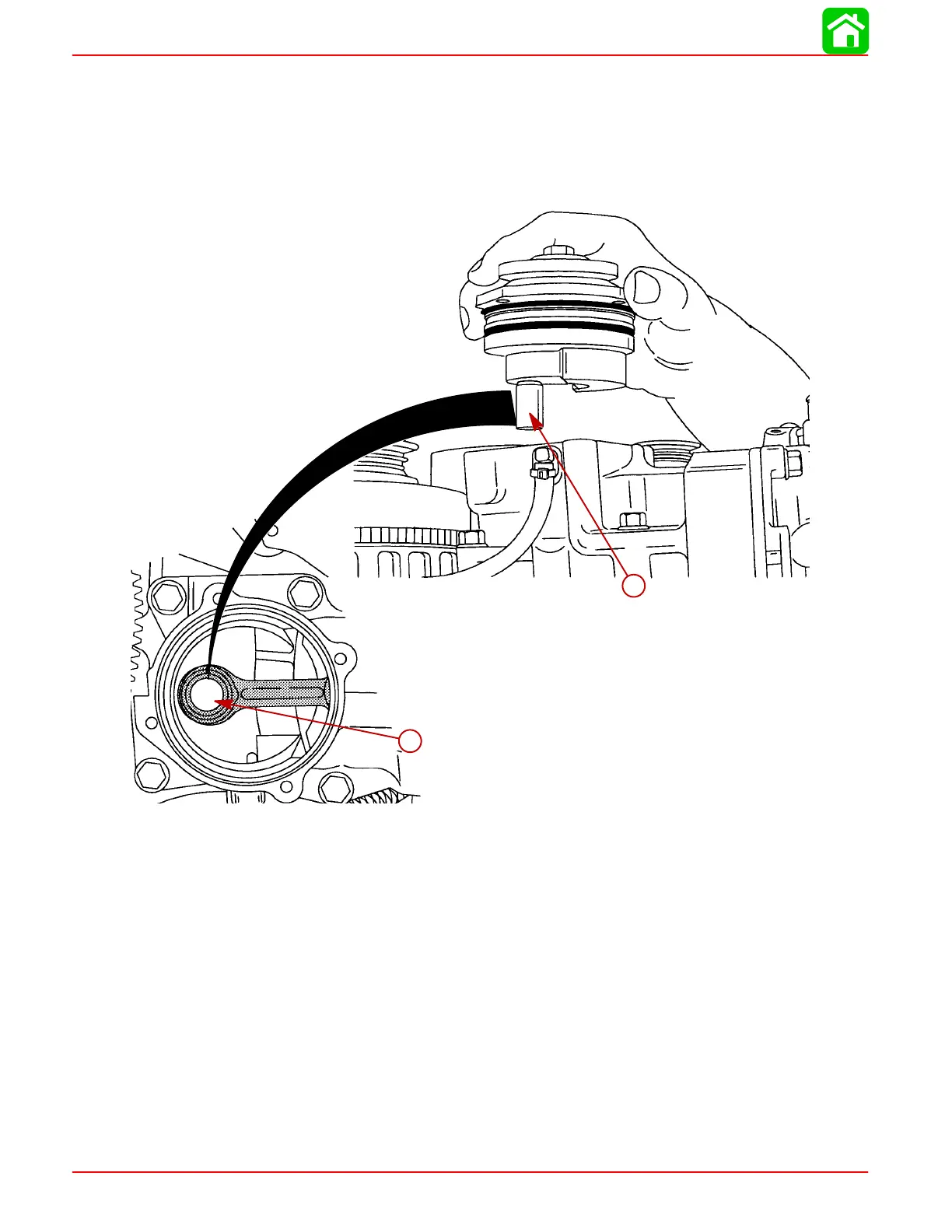

3. While rotating the pulley flange clockwise and counterclockwise, push the end cap

into the compressor. Continue rotating the flange until the end cap is all the way down

against the compressor body.

4. To confirm that the connecting rod journal has properly engaged with the connecting

rod, rotate the flange until you feel resistance from the piston trying to compress air

in the cylinder.

5. Apply Loctite 271 to the threads of the end cap retaining bolts and torque to 100 lb.

in. (11.5 Nm).

6. Apply Loctite 271 to the pulley retaining bolts. Torque to 170 lb. in. (19 Nm).

7. Install compressor/alternator belt.

8. Run engine to confirm that compressor is functioning correctly.

Loading...

Loading...