6

A

185mm

B

360mm

170mm

550mm

595mm

650mm

Refer

Chart

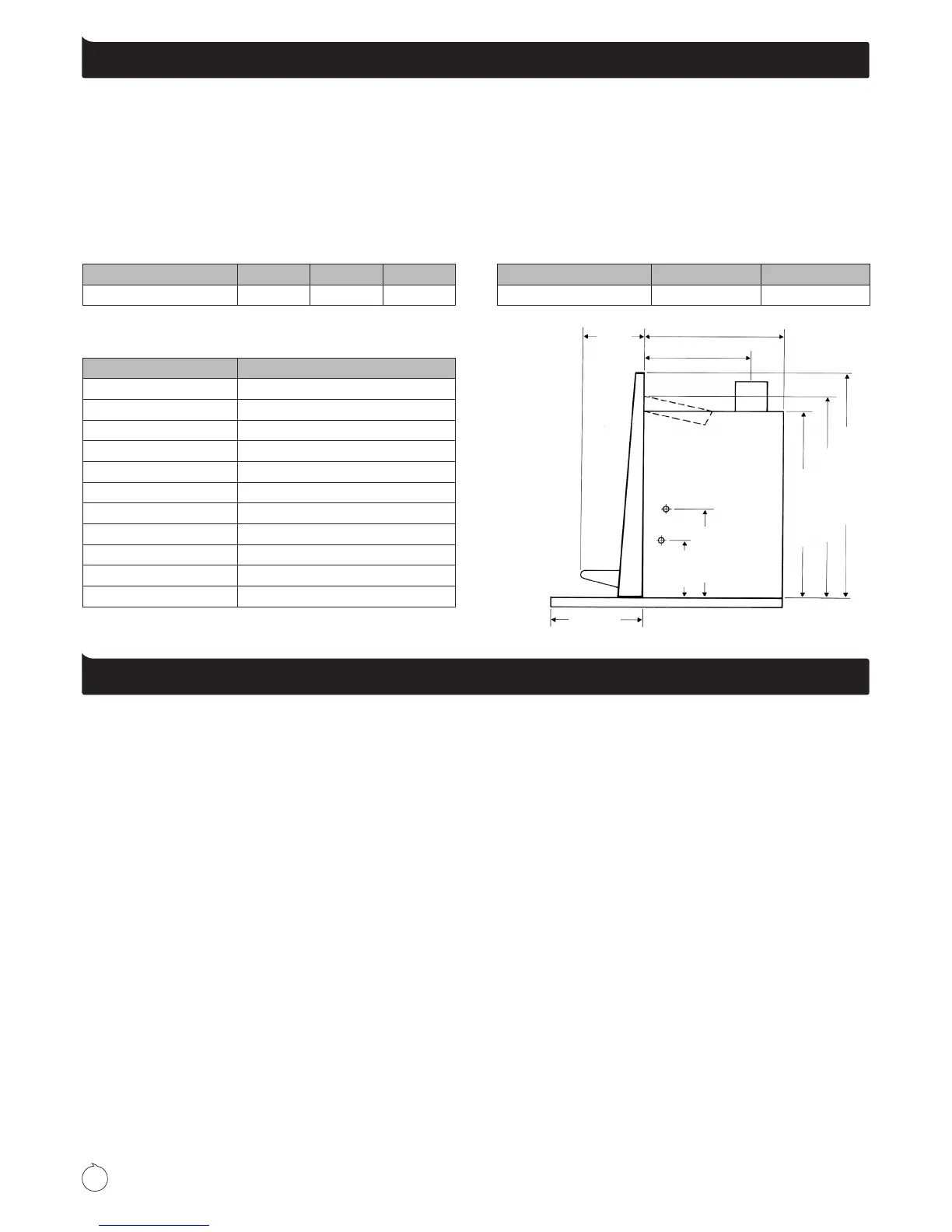

Firebox Model A B Width

LTD Insert 500mm 405mm 560mm

Fascia Model Base Width Body Width

Trend 810mm 810mm

Insert Raised LTD Insert

0mm 455mm insulated

10mm 455mm insulated

15mm 445mm insulated

20mm 436mm insulated

25mm 424mm insulated

30mm 408mm insulated

35mm 396mm insulated

40mm 366mm insulated

41mm & above 350mm insulated

45mm

50mm & above

Minimum Floor Protector projection and type

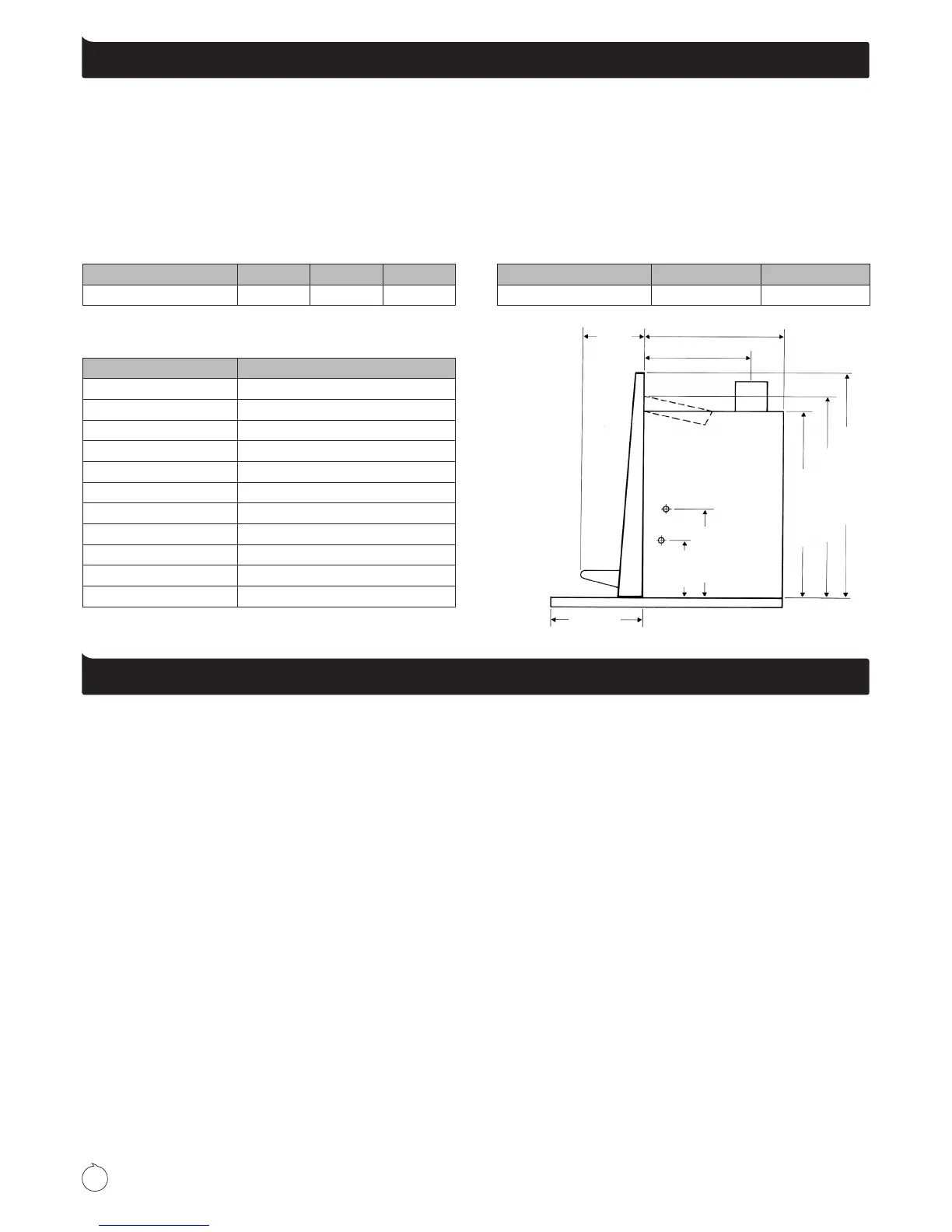

Diagram 4

Floor protector requirements

Metro replace inserts are designed to be installed direct

onto a concrete base. An insulated oor protector is required

to project in front of the Metro and must extend a minimum

of 200mm to each side of the door opening, making the

minimum oor protector width 825mm. The minimum oor

protector projection forward of the Metro is dependant on the

height of the replace insert above the combustible oor. The

following schedule of oor protector projections is measured

from behind the Metro fascia being the total oor protector

depth as shown in Diagram 4 below. Note, the heights

specied above the combustible oor can be achieved by: -

• The thickness of the oor protector

• Or by raising the replace insert

• Or a combination of the two

Wetbacks

The Metro LTD Insert can be tted with either of Pioneer’s 3kW

or 4kW wetback option. Only Pioneer’s cast jacket wetback

system as illustrated on page 9 of this manual should be tted

to a Metro. Alternative wetbacks will void the Metro’s emission

approvals and may seriously effect the performance of the

appliance and will void the owners warranty.

Both 3kW and 4kW wetback options can be tted to either side

of the rebox, with the connection pipe heights illustrated in

Diagram 4 above, please note: -

• It is recommended the return pipe has a minimum rise of

1 in 12. Performance will reduce as the distance to the

storage cylinder increases.

• The wetback must be connected to a vented system. To t

the wetback proceed as follows: -

1. Remove the brick from the inside of the rebox from the

side the wetback is to be tted too.

2. Expose the holes in the rebox through which the

connection pipes will pass.

The LTD Insert has a 3mm pressed washer covering these

two openings and two 6mm bolts which are tted inside

the rebox near the connection holes, remove these also.

3. Using a hole saw or snips, prepare the cabinet for the

connection pipes. Note, these holes should be a neat

t or have any excess gap covered or lled with high

temperature insulation.

4. Using the tube of sealant supplied with the wetback, apply

a liberal bead of sealant around both connection holes on

the inside of the rebox. On the rear of the wetback casting

apply the remaining contents of the tube equally around

both connection pipes and also the outer circumference

of the wetback which will face the inside rear wall of the

rebox. This will completely seal the wetback to the inside

rear wall of the re on installation.

5. Fit the wetback into the rebox and position the connection

pipes through the connection holes in the rebox.

6.

Fit two bolts through the slots provided in the wetback, align

the wetback so its front edge is parallel to the door opening

& secure the bolts. The wetback is ready for connection to

the storage cylinder by a registered plumber.

Loading...

Loading...