In order to remove the crankshaft flange, it is necessary to employ a tool

similar to that shown in 1llustr:ltion No.

13.

Engine Lubication.

The engine sump holds one gallon of oil and is re-

plenished through an e:rsily accessible filler on the off side of the engine.

The

oil level in the sump is quickly ascertained by means of the

"

dip-stick,"

which is just behind the oil filkr; this has two marks on it, the upper one

showing the level with the sump full, while the lower one is the danger line.

To

take

a rcadill,~ the cnfiinc

sl~oul~l

b~

szitched

off;

the dip-stick is with-

drawn, wiped clean, reinserted to its full length, withdrawn again, and then

read. These precautions are necessary, as when the engine is running the oil

in the sump is churned up, and splashes on the dip-stick may give a flilse

reading.

The

oil

level should be inspected every day before starting out, or every

100-150

miles on a long tour, and although it need not always be absolutely

full, the level should he kept well up, especially when the car is new and

never allowed to fall lower than half-way between the

"

full

"

and

"

danger

"

marks. At the same time overfilling should he c:irefully avoided as this

causes the oiling up of the plugs.

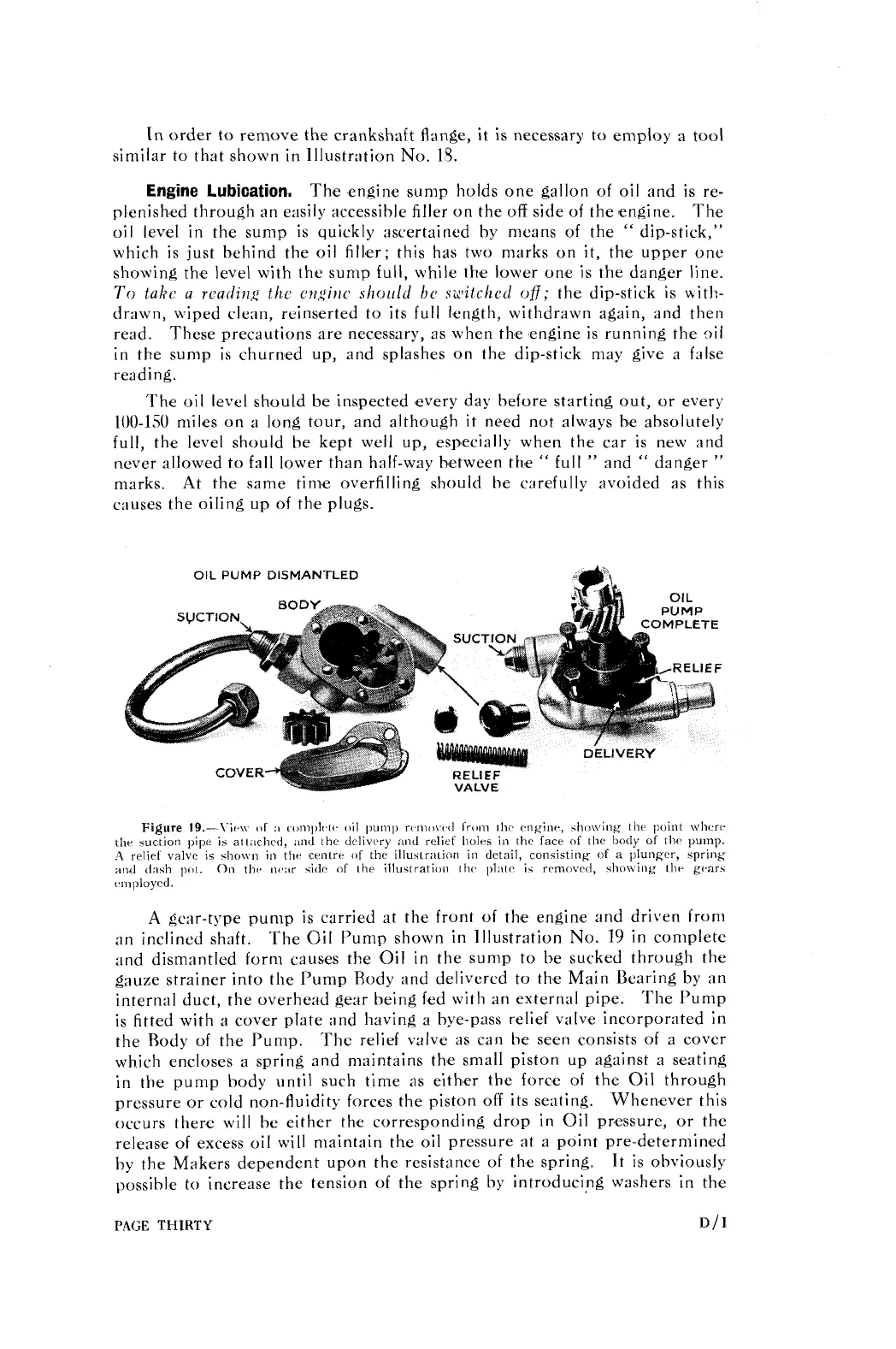

OIL

PUMP

DISMANTLED

Figure

19.-\.ir.\\. :I rornl)lr,c(. oil pump r(.rno\.(.d I'r,~m thc engine, sho\\,ing tlw point \vIic.r~-

the wction pipe

is

att:~chcd,

:~nd

thc delivery

and

relief holes in thc face

OS

thc body of thr pump.

A

relief valve

is

sho\vn in tlir crnlrr of thc illuslra~ion in detail, consisting

of

a

plunger,

spring

and dash

1x1~.

011

tlw ni3:Ir sidc of the illustration tlw

plate

is removed,

she\\-ing

~hr gl-arh

(.niploycd.

A

gear-type pump is carried at the front

of

the engine and driven from

an inclined shaft.

The

Oil

Pump shown in Illustration No.

19

in complete

and dismantled form causes the Oil in the sump to be sucked through the

gauze strainer into the

I'ump Rody and delivered to the Main Bearing by an

internal duct, the overhead gear being fed with an external pipe. The Pump

is fitted with

a

cover plate and having a bye-pass relief valve incorporated in

the Rody of the I'ump. Thc relief valve as can he seen consists of a cover

which encloses a spring and maintains the small piston up against a seating

in the pump

body until such time as eithser the force of the Oil through

pressure or cold non-fluidity forces the piston off its seating.

Whenever this

occurs there will be either the corresponding drop in

Oil

pressure, or the

release of excess oil will maintain the oil pressure at a point pre-determined

by the Makers dependent upon the resistance of the spring.

It is

obviously

possible

to

increase the tension of the spring by introducing washers in the

PAGE

THIRTY

D/I

Loading...

Loading...