employed to describe the Clutch plirts hy different people, but in this Works

they are described as follows

:

-

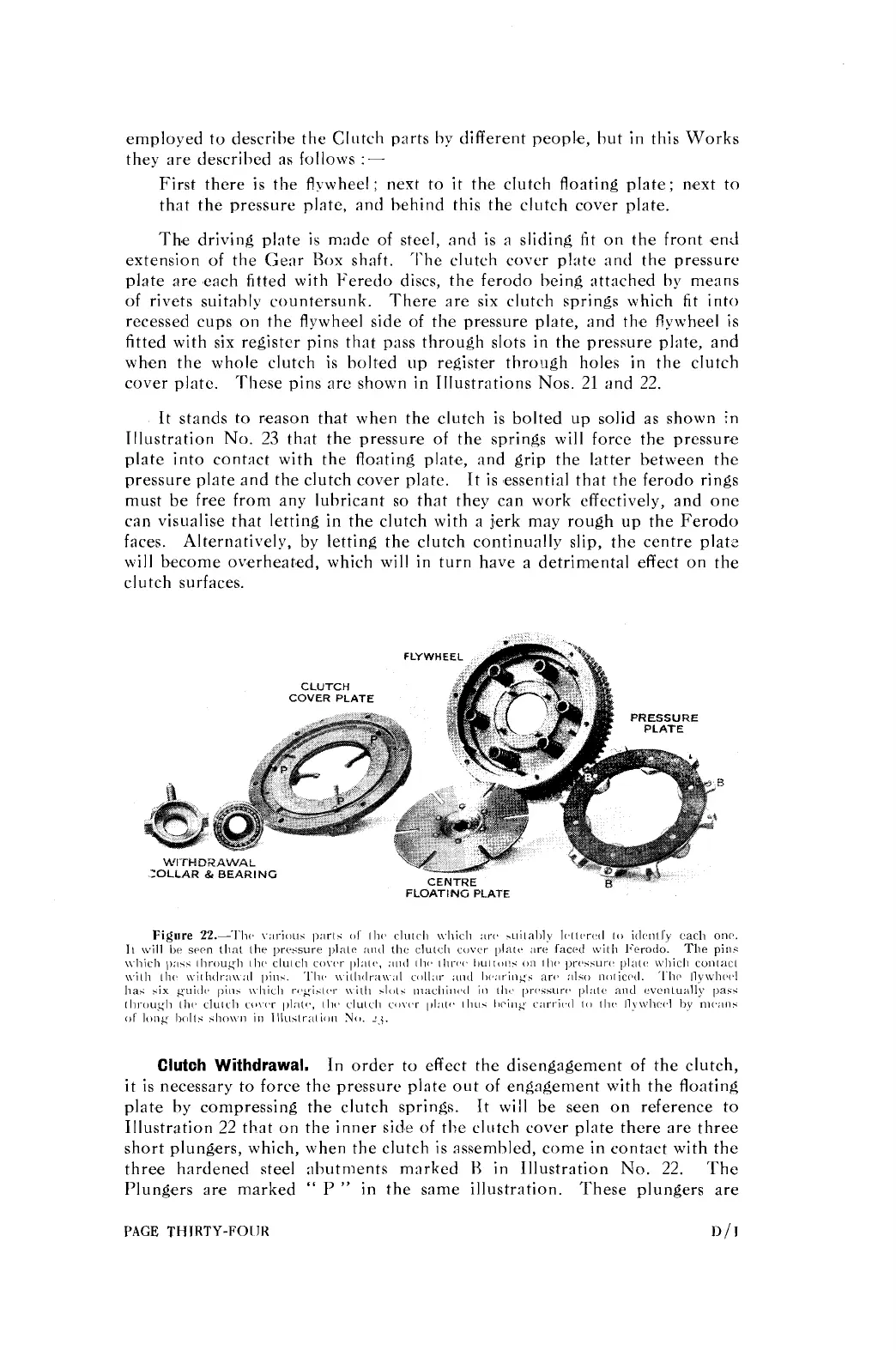

First there is the flywheel; nest to it the clutch floating plate; next to

that the pressure plate, and behind this the clutch cover plate.

Th'e driving plate is made of steel, and is

a

sliding fit on the front end

extension of the Gear Rox shaft. 'I'he clutch cover plate and the pressure

plate are each fitted with Feredo discs, the ferodo being attached by means

of rivets suitably countersunk. There are six clutch springs which fit into

recessed cups on the flywheel side of the pressure plate, and tlie flywheel is

fitted with six register pins that pass through slots in the pressure plate, and

when the whole clutch is

bolted up register through holes in tlie clutch

cover plate. These pins are shown in Illustrations Nos.

21

end

22.

It stands to r,eason that when the clutch is bolted up solid as shown in

Illustration No.

23

that the pressure of the springs will force the pressure

plate into contact with the floating plate, and grip the latter between the

pressure pl:~te and the clutch cover plate. It is essential that the ferodo rings

must be free from any lubricant so that they can work effectively, and one

can visualise that letting in the clutch with a jerk may rough up the Ferodo

faces. Alternatively, by letting the clutch continually slip, the centre

plat-

will become overheated, which will in turn have a detrimental effect on the

clutch surfaces.

FLYWHEEL

CLUTCH

COVER PLATE

B

-0LLAR

&

BEARING

FLOAT1

NC

PLATE

PAGE

THIRTY-FOIJK

1)

/

1

Loading...

Loading...