Illustr:~tion

No.

26

is a picture of the rear axle casing with the complete

differential assembly removed, and one axle shaft and hub removed as well.

Refore the differential can be withdrawn, it is necessary to withdraw the axle

shafts.

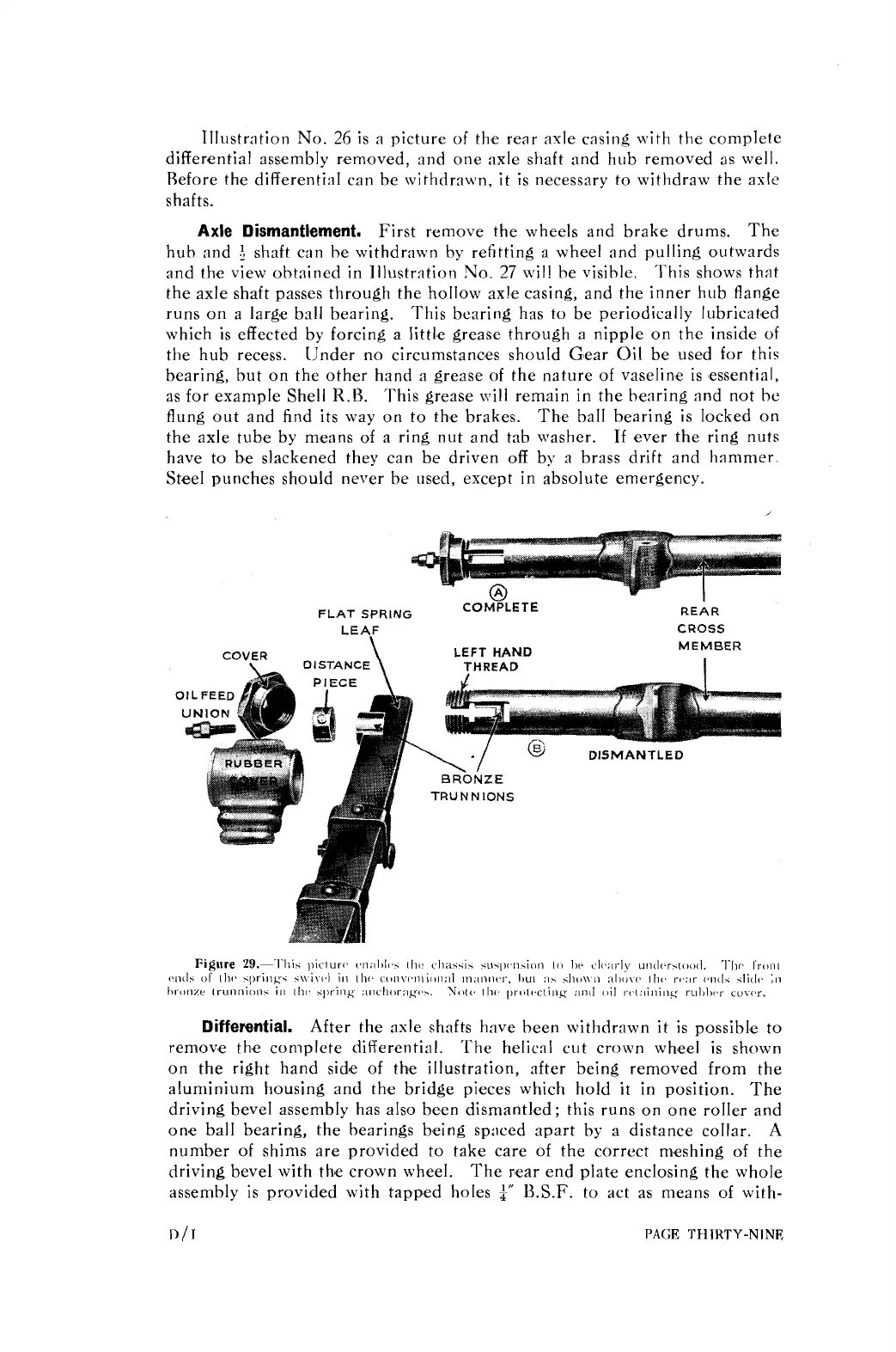

Axle Dismantlement.

First remove the wheels and brake drums. The

hub and

shaft can be withdrawn by refitting a wheel and pulling outwards

and the view obtained in Illustrntion No.

27

wil! be visible.

This shows th:lt

the axle shaft passes through the hollow axle casing, and the inner hub flange

runs on a large ball bearing. This bearing has to be periodically lubricated

which is effected by forcing a little grease through

a

nipple on the inside of

the hub recess. Under no circumstances should Gear

Oil

be used for this

bearing, but on the other hand

a

grease of the nature of vaseline is essential,

as for example Shell

R.B.

This grease will remain in the bexing and not be

flung out and find its way on to the brakes. The ball bearing is locked on

the axle tube by means of a ring nut and

tab washer. If ever the ring nuts

have to be slackened they can be driven off by a brass drift and hammer

Steel punches should never be used, except in absolute emergency.

FLAT

SPRING

COMYLETE

LEAF

DISTANCE

\

LEFT

HAND

THREAD

I

REAR

CROSS

MEMBER

I

\

"/

DISMANTLED

BRONZE

TRUNNIONS

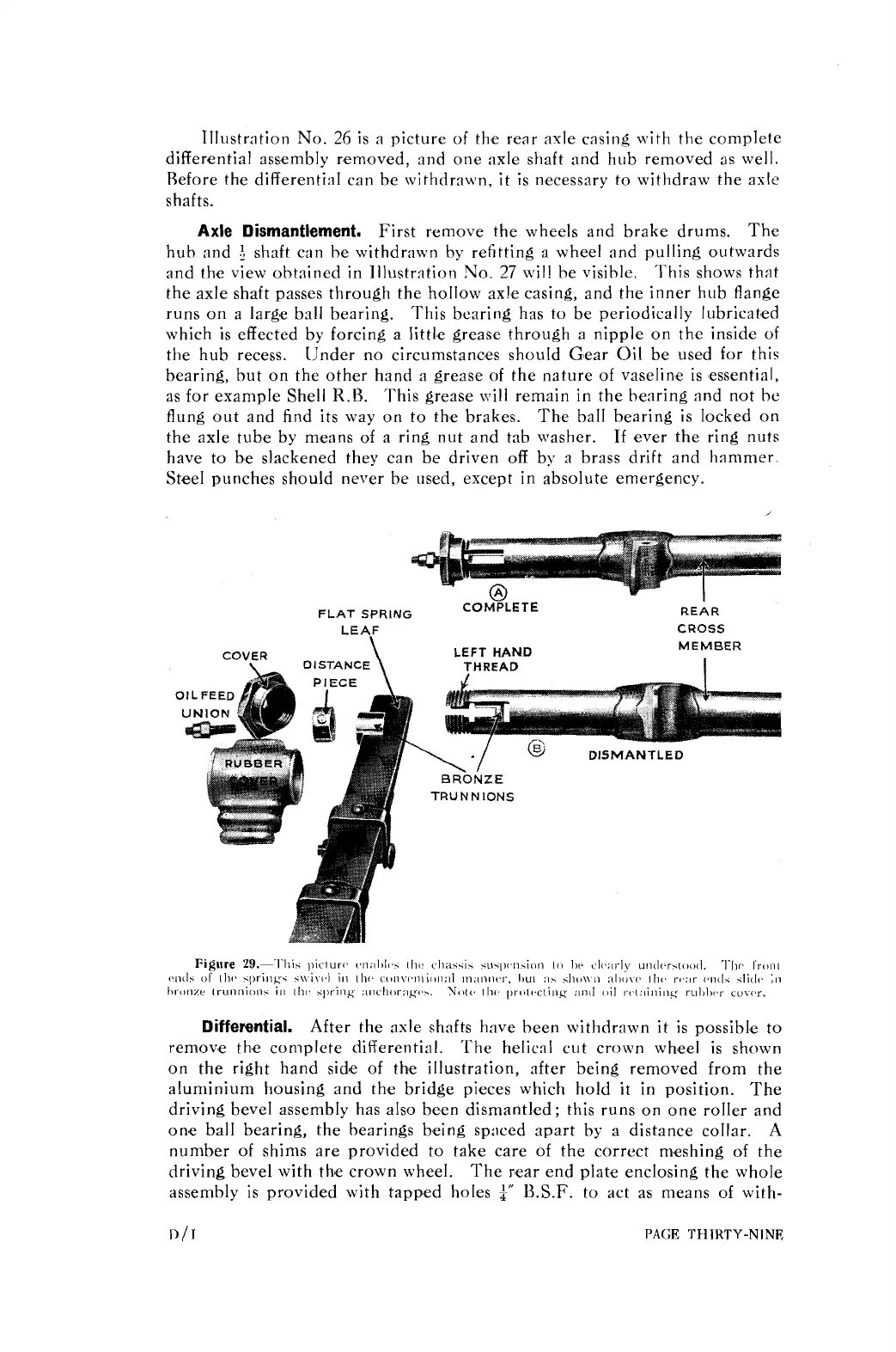

Differential.

After the axle shafts have been withdrawn it is possible to

remove the complete differential. 'The helical cut crown wheel is shown

on the right hand sidle of the illustration,

after being removed from the

aluminium housing and the bridge pieces which hold

it

in position. The

driving bevel assembly has also been dismantled; this runs on one roller and

one ball bearing, the bearings being spaced apart by a distance collar.

A

number of shims are provided to take care of the correct meshing of the

driving bevel with

thse crown wheel. The rear end plate enclosing the whole

assembly is provided with tapped holes

l"

B.S.F.

to act as means of with-

D

/

I

PAGE

THIRTY-NINE

Loading...

Loading...