H

THE

BEAll

AXU----

Operations

(a), (b)

and

(c)

merely

call for

the

fitting of

the

new

parts

in

the

positions

occupied by

the

old.

The

remaining

operations

entail special

precautions

and

are

detailed

subsequentl

y.

The

axle

or

half-shafts,

rear

hub bearlngs,

brake-

drums

and

shoe

mechanism can all be

dismantled

and

replaced

with

the

axle in position on

the

car.

Seetion

0.6

DISMANTLING THE AXLE

AND

REMOVING THE DIFFERENTIAL

ASSEMBLY

Remove

the

axle

from

the

car

as

detailed

in Section

H.4.

To dismantle

the

axle, first

remove

the

hub and

brake-d

ru

masse

mblj es as in Section H. I, and

the

brake

plates as in Section

H.2.

Remove

the

axle

half-shatts

as detailed in Section

H.3.

Remove

the

series

of

bolts joining

the

axle casing

and

cover

together

and carefully

part

them,

taking

care

to

see

that

both

halves

of

the

axle

are

suitably

supported

to

avoid damage

to

the

differential assembly.

The

withdrawal

of

the

axle

cover

from

the

casing

releases

the

differential and

crown

wheel

assembly,

which can now be

withdrawn.

Note

that

spacers

are

fitted

between

the

differential

bearlngs and

the

bearing housings and

that

they

are

important

as

they

control

the

position

of

the

differen-

tial assembly in

the

axle.

It Is essential

that

they

be replaced in

their

original

locations on assembly, so make a

note

of

the

positions

from

which

they

are

removed.

Note.-AII

original spacers are marked ols and njs.

It

must

also be

noted

that

the

axle casing and

cover

are

marked

on

the

surface of

one

of

the

outside

webs

or

tubes

with

one

of

the

following figures

:-Zero.

I, 2, 3, 4, 5, 6, all being positive.

Seetion

0.7

DISMANTLING THE DIFFERENTIAL

AND

CROWN

WHEEL

ASSEMBLY

When

the

differential assembly has been removed

from

the

axle casing, as

detailed

in Section H.6, it is

dismantled by bending back

the

tab

of

the

locking.

plate

of

the

bolt locating

the

differential pinion shaft,

withdrawing

the

bolt

and

removing

the

shaft.

The

differential pinions can

now

be

removed

from

the

differential cage by swinging

them

round

with

H.B

their

dished

thrust

plates until

they

register

with

the

openings in

the

differential cage,

through

which

they

can be

removed.

The

differential cage gears can

then

be

withdrawn

from inside

the

differential

through

the

openings,

togethe

r

wit

h

the

ir

th

rust

washers.

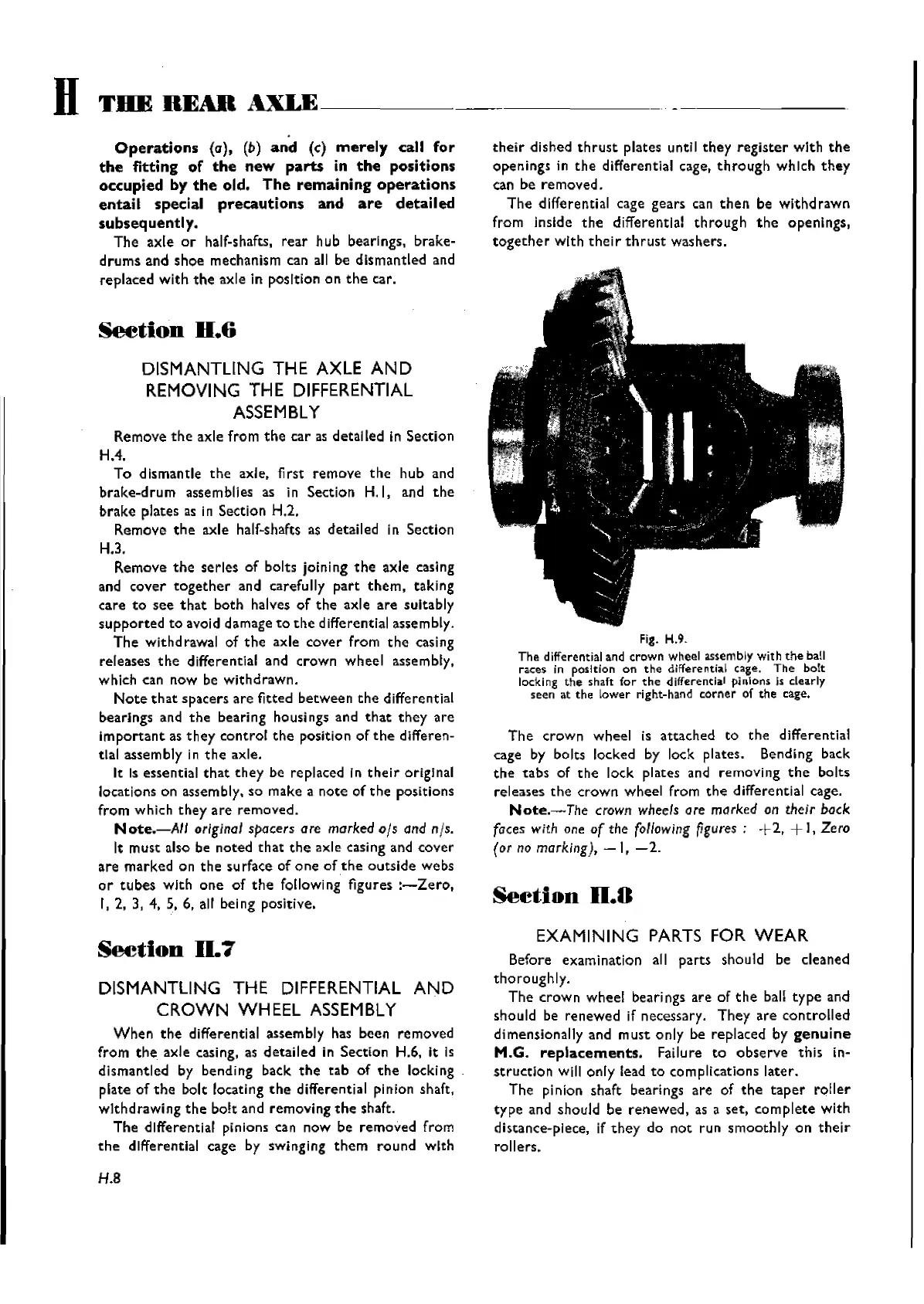

Fig. H.9.

The

differential and

crown

wheel assembly with

the

ball

races in position on

the

differential cage.

The

bolt

locki ng

the

shaft

for

the

differential pi

nlons

Is clearly

seen at

the

lower

right-hand

corner

of

the

cage.

The

crown

wheel

is

attached

to

the

differential

cage by bolts locked by lock plates. Bending back

the

tabs

of

the

lock plates and

removing

the

bolts

releases

the

crown

wheel

from

the

differential cage.

Note.-The

crown

wheels

are

marked on their bock

faces with one

of

the

following

figures;

-1-2,

-I-

I, Zero

(or no marking),

-1, -2.

Seetion

0.8

EXAMINING

PARTS

FOR

WEAR

Before

examination

all

parts

should be cleaned

thoroughly.

The

crown

wheel

bearings

are

of

the

ball

type

and

should be

renewed

if necessary.

They

are

controlled

dimensionally and

must

only

be replaced by

genuine

M.G.

repla.cements.

Failure

to

observe

this

in-

struction

will

only

lead

to

complications

later.

The

pinion shaft bearings

are

of

the

taper

roller

type

and should be

renewed,

as a

set,

complete

with

distance-piece, if

they

do

not

run

smoothly

on

their

rollers.

Wishvilles Classic

Automobile Library

Loading...

Loading...