the

flange.

Put

a little grease

01'1

the

sump

flange, this

will

ensure

future

easy removal.

Should

the

engine be

turned

while

the

sump

is

removed

or

drained,

thus

emptying

the

suction

passages.

the

pump

will have

to

be primed with oil

by disconnecting

the

delivery pipe on early engines.

Later

models have a special priming plug on

the

oil

pump

body.

The

main feed oil gallery may also be

primed

through

the

special plug provided for this

purpose

in

the

cylinder block above

the

pump

(see

Fig. A.S).

Seetion

1\..3

REMOVAL OF THE OIL PUMP

Drain

the

radiator

and slack off

the

top

and

bottom

water

hoses.

R.emove

the

front

engine mounting bolts holding

the

engine

bracket

to

the

rubber

block. Slightly

jack up

the

engine at

the

front.

This allows

the

pump

to clear

the

frame

member.

Note.-Qn

LHD

models the steering

column

passes

immediately

above

the oil pump. and it is not

possible

to

lift the engine without first raising the steering

column.

To

do this,

first

remove

the split pins and nuts

(rom

the

three bolts

at

the steering

column

universal

Joint,.

slacken

the bolt and nut

holding

the steering

column

to the

body

steady bracket, and take out the nut and bolt

from

the

support

clip under the

dash.

The

steering

wheel

may

now be

lowered

so that the

column

clears the oil pump,

and the

engine

may be lifted.

Detach

the

main

011

pipe from

the

filter

to

the

pump

on early models,

or

remove

filter bowl and

element

on

later

models.

R.emove

the

eight

bolts securing

the

pump

to

the

cylinder block. This will release

the

cover.

Lift off

the

cover

(rom

the

pump

body. This will

release

the

driven gear, which can easily be

withdrawn.

R.emove

the

pump

by gently tapping

the

side of

the

body and

withdrawing

it downwards.

Screw

a sultable

extraeto

r

into

the

end

of

the

driven

gear

shaft and

withdraw

it from

the

cylinder block if

it

is

required

to

remove

this.

Seetion

A.4

DISMANTLING,

REASSEMBLING

AND

REPLACING THE OIL PUMP

After

withdrawing

the

pump from

the

cyli

nder

block

as described in Section A.3,

remove

the

circlip securing

the

driving

gear

to

the

oil pump shaft and helical gear.

Using

a

suitable

drift,

tap

the

oil pump shaft and

gear

partly

through

the

driving gear.

Extract

the

key

and

gear

before

completely

removing

the

shaft, other-

wise

the

key will damage

the

bush.

C M.G. Midget (Serie$ .. TO

"),

lssue 3

(E)

79345-1

/S3

-THE

ENGINE

A

Clean all parts, examine and

check

for

wear.

The

gear

depth

Is 1·378

In.-·0016

11'1.-·0024 in.

(35

mm.-·04

mm.~·06

mm.)

with

a

diameter

of

1·2678

in.+ool

in. (32'2

mm.+025

mm.).

The

housing

depth

is 1·378

in.+·0012

in. (3S

rnm.'}

·03 mm.) with a

bore

of 1·2795

in.+·ool

in.-·OOO6 in.

(32-5

mm.+-015

mm.-·OIS

mm.).

This results in a

gear

end float of

-0016

in.

to

·003S

In. (-04mm.

to·09

mm.) with

the

end

cover

fitted,

and a rad

ia] cfearance of ·0056 in. to ·0064 in. (,145 mm,

to

·162 mrn.). The backlash

between

the

teeth

Is

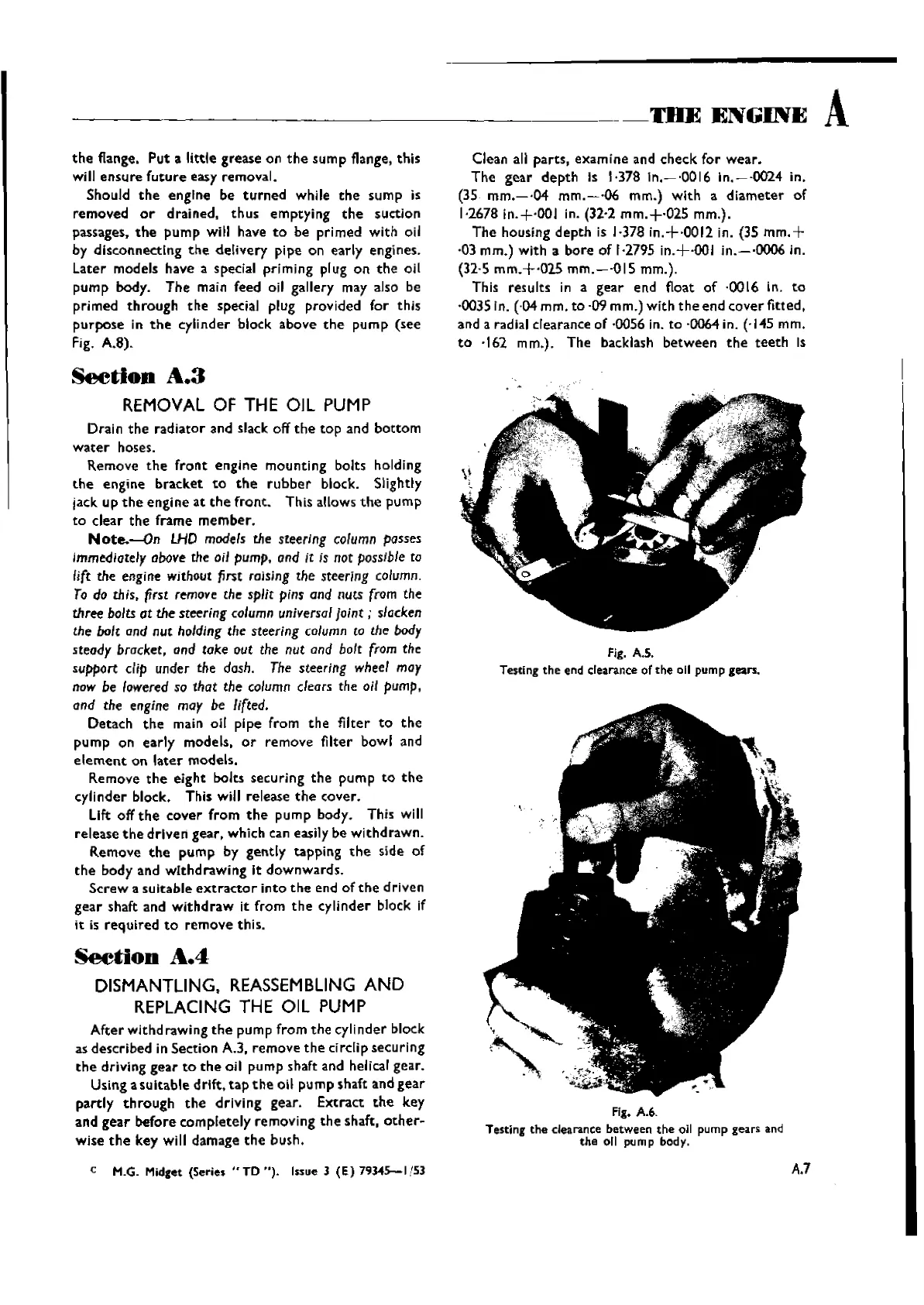

fig.

AS.

Testing

the end

clearance

of the

011

pump

gears.

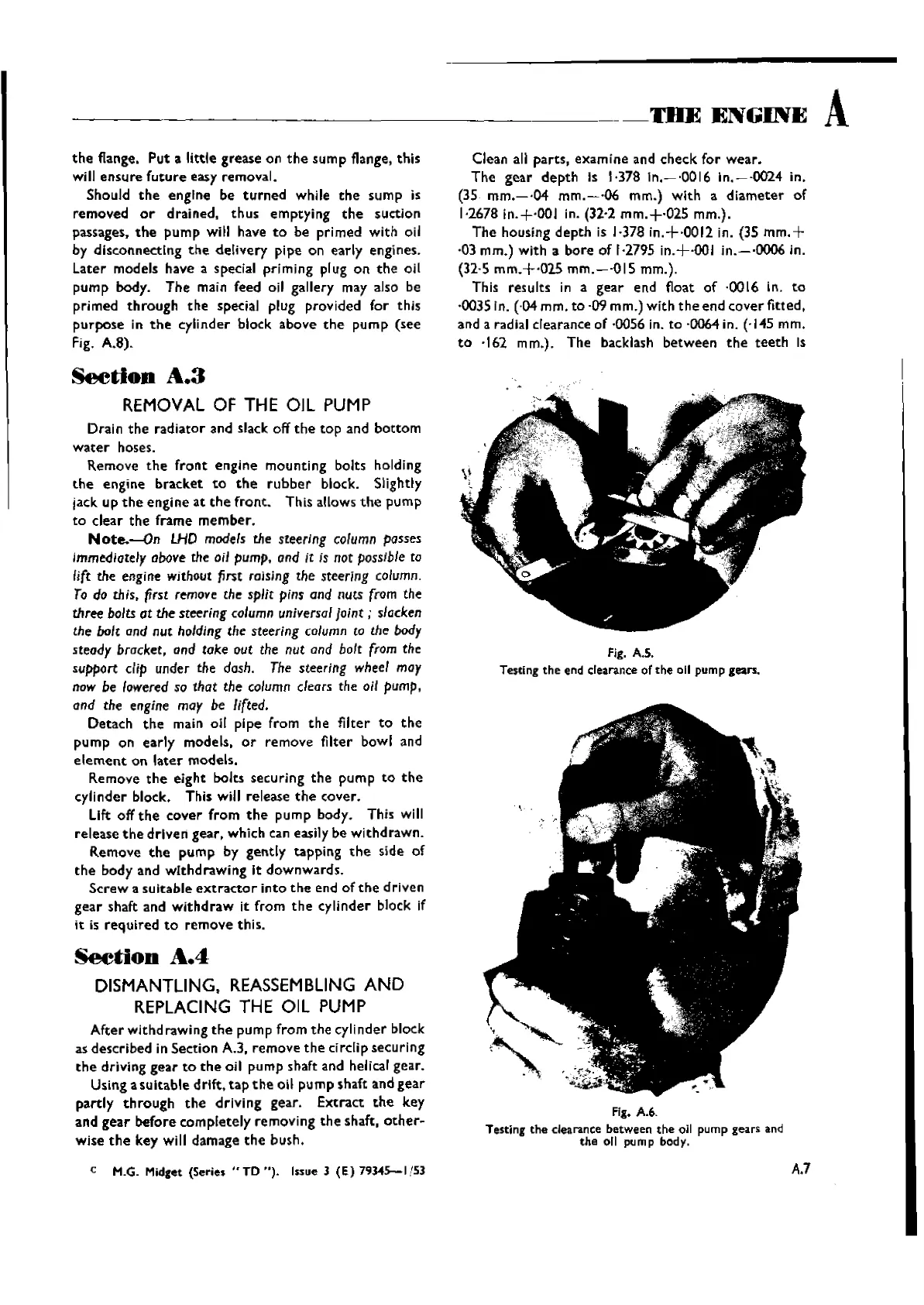

fig.

A.6.

Testing

the

clearance

between

the oil pump gears

and

the off pump

body.

A.7

Wishvilles Classic

Automobile Library

Loading...

Loading...