8

THE

FUEL

SYSTEM-----.---------

of

the

float-chamber lid.

The

prongs of

the

lever

should

just

rest

on

the

bar

(see Fig.

B.17)

when

the

needle is on its seating. If this is

not

so,

the

lever

should be

reset

at

the

point

where

the

prongs

meet

the

shank.

Care

must be

taken

not

to

bend

the

shank, which must be perfectly flat and at

right

angles

to

the

needle when it is on its seating.

Section

B.ll

CENTRING THE JET

First remove

the

clevis pin at base of

the

jet,

which

attaches

the

jet

head

to

the

Jet operating

lever;

with-

draw

the

jet

completely, and remove

the

adjusting

nut

and

the

ad] ustlng

nut

spring. Replace

the

adjust-

ing

nut

without

its spring and screw it up

to

the

highest

position. Slide

the

jet

into

position until

the

jet

head

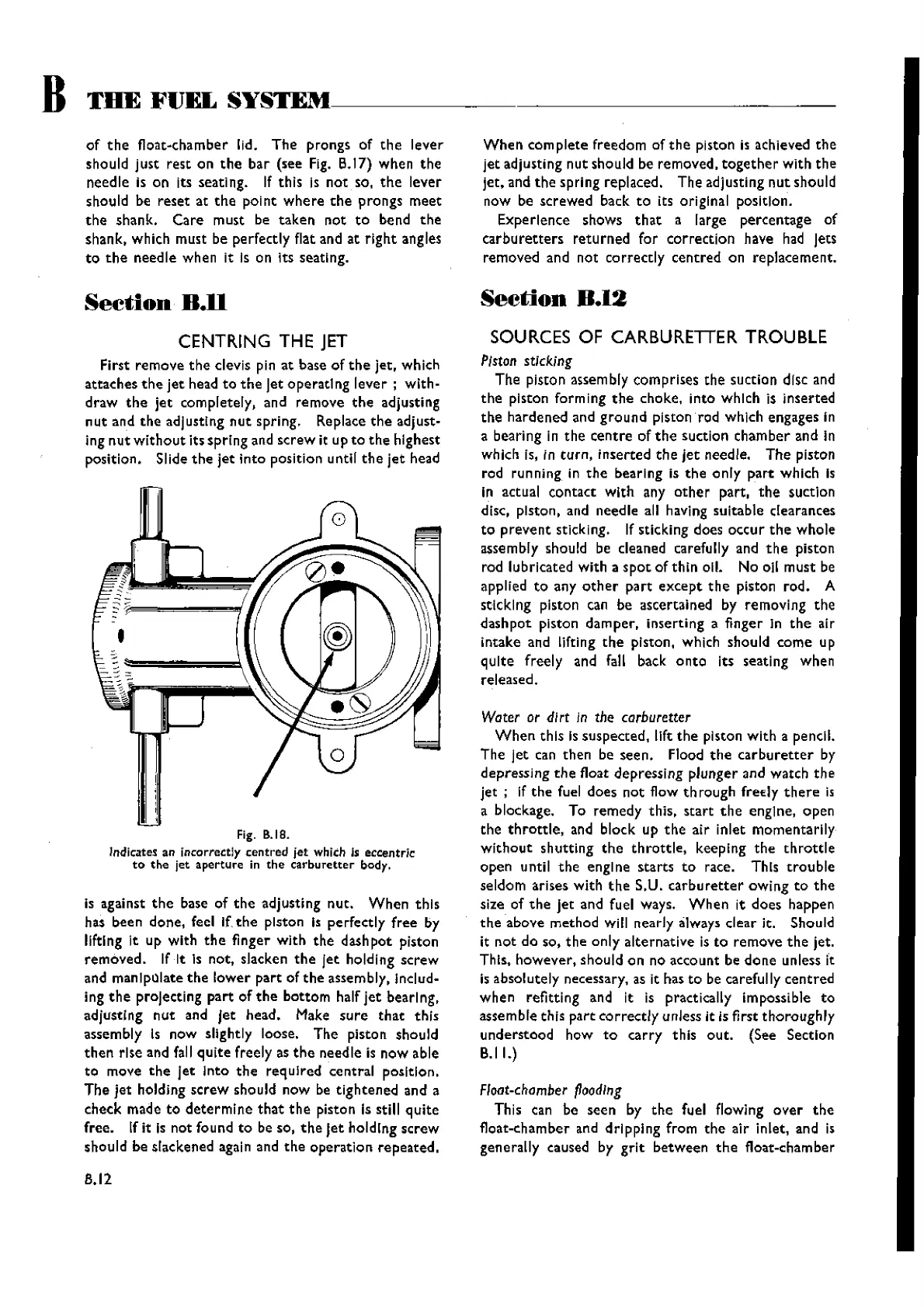

Fig. B.18.

Indicates an incorrectly centred

jet

which Is eccentric

to

the

jet

aperture

in

the

carburetter

body.

is against

the

base of

the

adjusting nut.

When

this

has been done, feel

If

the

piston is perfectly free by

lifting it up with

the

finger with

the

dash

pot

piston

removed. If It Is not, slacken

the

jet

holding screw

and manipulate

the

lower

part

of

the

assembly, lnclud-

ing th e proJecti ng

part

of

the

bottom

half

jet

bearl ng,

adjusting

nut

and let head. Make

sure

that

this

assembly Is now slightly loose. The piston should

then

rise and fall

quite

freely as

the

needle is now able

to move

the

jet Into

the

required central position.

The

jet

holding

screw

should now be tightened and a

check made

to

determine

that

the

piston is still

quite

free. Ifit is not found

to

be so,

the

jet

holding screw

should be slackened again and

the

operation

repeated.

B.12

When

complete freedom

ofthe

piston is achieved

the

jet

adjusting nut should be removed,

together

with

the

jet.

and

the

spring replaced. The adjusting

nut

should

now be screwed back

to

its original position.

Experience shows

that

a large percentage of

carburetters

returned

for correction have had Jets

removed and not correctly

centred

on replacement.

Section

B.12

SOURCES

OF CARBURETIER TROUBLE

Piston

sticking

The piston assembly comprises

the

suction disc and

the

piston forming

the

choke, into which is inserted

the

hardened and

ground

piston rod which engages in

a bearing in

the

centre

of

the

suction chamber and In

which is, In

turn,

inserted

the

jet

needle.

The

piston

rod running in

the

bearing is

the

only

part

which is

in actual contact

with

any

other

part,

the

suction

disc, piston, and needle all havlng suitable clearances

to

prevent

sticking. If sticking does

occur

the

whole

assembly should be cleaned carefully and

the

piston

rod lubricated with a

spot

of thin

011.

No

011

must be

applied

to

any

other

part

except

the

piston rod. A

sticking piston can be ascertained by removing

the

dashpot piston damper, inserting a finger In

the

air

intake and lifting

the

piston. which should

come

up

quite

freely and fall back

onto

its seating when

released.

Water or dirt in the carburener

When

this is suspected,

11ft

the

piston with a pencil.

The Jet can then be seen. Flood

the

carburetter

by

depressing

the

float depressing plunger and watch

the

jet;

If

the

fuel does

not

flow th rough freEly th

ere

is

a blockage. To remedy this,

start

the

engine, open

the

throttle,

and block up

the

air inlet momentarily

without

shutting

the

throttle,

keeping

the

throttle

open until

the

engine

starts

to

race. This

trouble

seldom arises with

the

S.U.

carburetter

owing

to

the

size of

the

jet

and fuel ways.

When

It does happen

the

above method will nearly always clear it. Should

it

not

do so,

the

only alternative is

to

remove

the

jet.

This, however, should on no account be

done

unless it

is absolutely necessary, as it has

to

be carefully

centred

when refitting and it is practically impossible to

assemble this

part

correctly

unless it is first thoroughly

understood how

to

carry

this

out.

(See Section

B.II.)

Float-chamber

~oodlng

This tan be seen by

the

fuel flowing

over

the

float-chamber and drl pplng from

the

air inlet, and is

generally caused by

grit

between

the

float-chamber

Wishvilles Classic

Automobile Library

Loading...

Loading...