-------------ELECTRI~1U

EQUIPMENT

N

between

the

back of

the

armature

"A"

and

the

regulator

frame"

B."

(ii) Press back

the

armature

against

the

regulator

frame and down on to

the

top of

the

bobbin

core

with

the

gauge in position, and lock

the

armature

by

tightening

the

two

fixing screws.

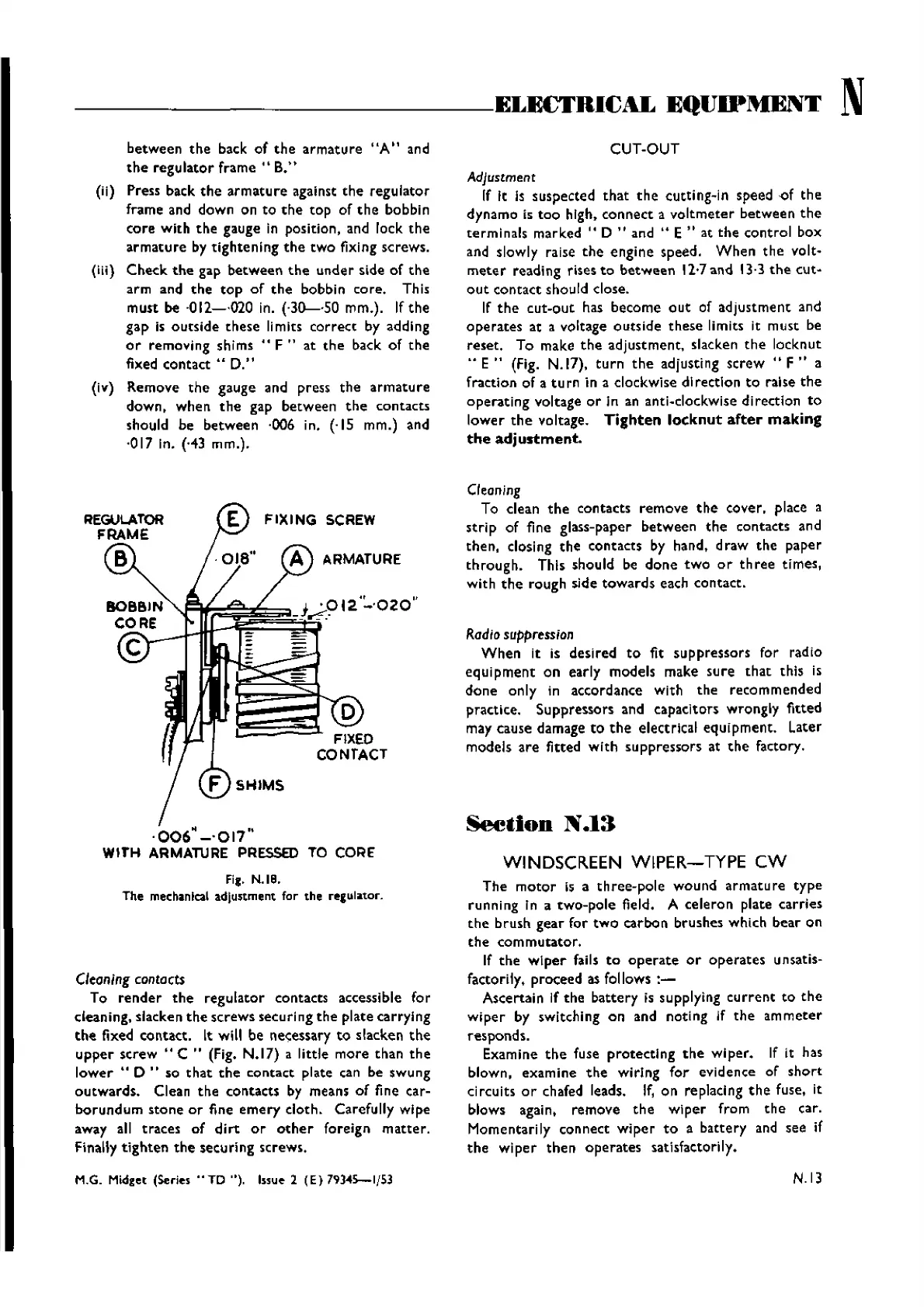

(iii)

Check

the

gap

between

the

under side of

the

arm and

the

top

of

the

bobbin core. This

must be '012-·020 in. (·30--·50 mm.). If

the

gap is

outside

these

limits

correct

by adding

or

removing

shims"

F"

at

the

back of

the

fixed contact ..

D."

(iv) Remove

the

gauge and press

the

armature

down, when

the

gap between

the

contacts

should be between ·006 in. (·15 mm.) and

·017 In. ('43 mm.).

FIXING

SCREW

ARMATURE

F SHIMS

·006"

-'017"

WITH

ARMATURE

PRESSED

TO

CORE'

FiC.

N.IS.

The mechanical adjunment for the regulator.

Cleaning

contacts

To

render

the

regulator contacts accessible for

clean ing. slacke n

the

screws securlng

the

piate carrylng

the

fixed contact. It will be necessary

to

slacken

the

upper

screw"

C " (Fig. N.17) a little

more

than

the

lower"

0 " so

that

the

contact plate can be swung

outwards.

Clean

the

contacts by means of fine car-

borundum

stone

or

fine

emery

cloth. Carefully wipe

away all traces of

dirt

or

other

foreign

matter.

Finally

tighten

the

securing screws.

M.G. Midget (Series .. TD "). Issue 2

(E)

79).045-1/53

CUT-OUT

Adjustment

If It Is suspected

that

the

cutnng-ln speed

of

the

dynamo is

too

high.

connect

a

voltmeter

between

the

te rminals mar ked " D " and .. E " at

the

control box

and slowly raise

the

engine speed.

When

the

volt-

meter

reading rises

to

between

12·7and 13·3

the

cut-

out

contact should close.

If

the

cut-out

has become

out

of adjustment and

operates

at a voltage outside

these

limits it must be

reset. To make

the

adjustment, slacken

the

locknut

..

E"

(Fig.

N.ll),

turn

the

adjusting screw ..

F"

a

fraction of a

turn

in a clockwise direction

to

raise

the

operating voltage

or

In an anti-clockwise direction

to

lower

the

voltage.

Tighten

locknut

after

making

the

adjustment.

C'eaning

To clean

the

contacts remove

the

cover. place a

strip

of fine glass-paper between

the

contacts and

the

n, closlng

the

contacts by hand. draw

the

paper

through.

This should be

done

two

or

three

times,

with

the

rough side

towards

each contact.

Radio

suppression

When

it is desired

to

fit suppressors for radio

equipment

on early models make

sure

that

this is

done

only in accordance with

the

recommended

practice. Suppressors and capacitors wrongly fitted

may cause damage

to

the

electrical equipment. Later

models

are

fitted

with

suppressors at

the

factory.

Seetion

N

.13

WINDSCREEN WIPER-TYPE

CW

The

motor

is a

three-pole

wound

armature

type

running In a two-pole field. A celeron plate carries

the

brush. gear for

two

carbon brushes which bear on

the

commutator.

If

the

wiper

fails

to

operate

or

operates

unsatis-

factorily. proceed as follows

:-

Ascertain If

the

battery is supplying

current

to

the

wiper

by switching on and noting If

the

ammeter

responds.

Examine

the

fuse

protecting

the

wiper. If it has

blown, examine

the

wiring

for

evidence of

short

circuits

or

chafed leads. If, on replacing

the

fuse, it

blows again. remove

the

wiper

from

the

car.

Momentarily connect

wiper

to

a battery and see if

the

wiper

the

n

operates

satisfactori ly.

N.13

Wishvilles Classic

Automobile Library

Loading...

Loading...