Page 17

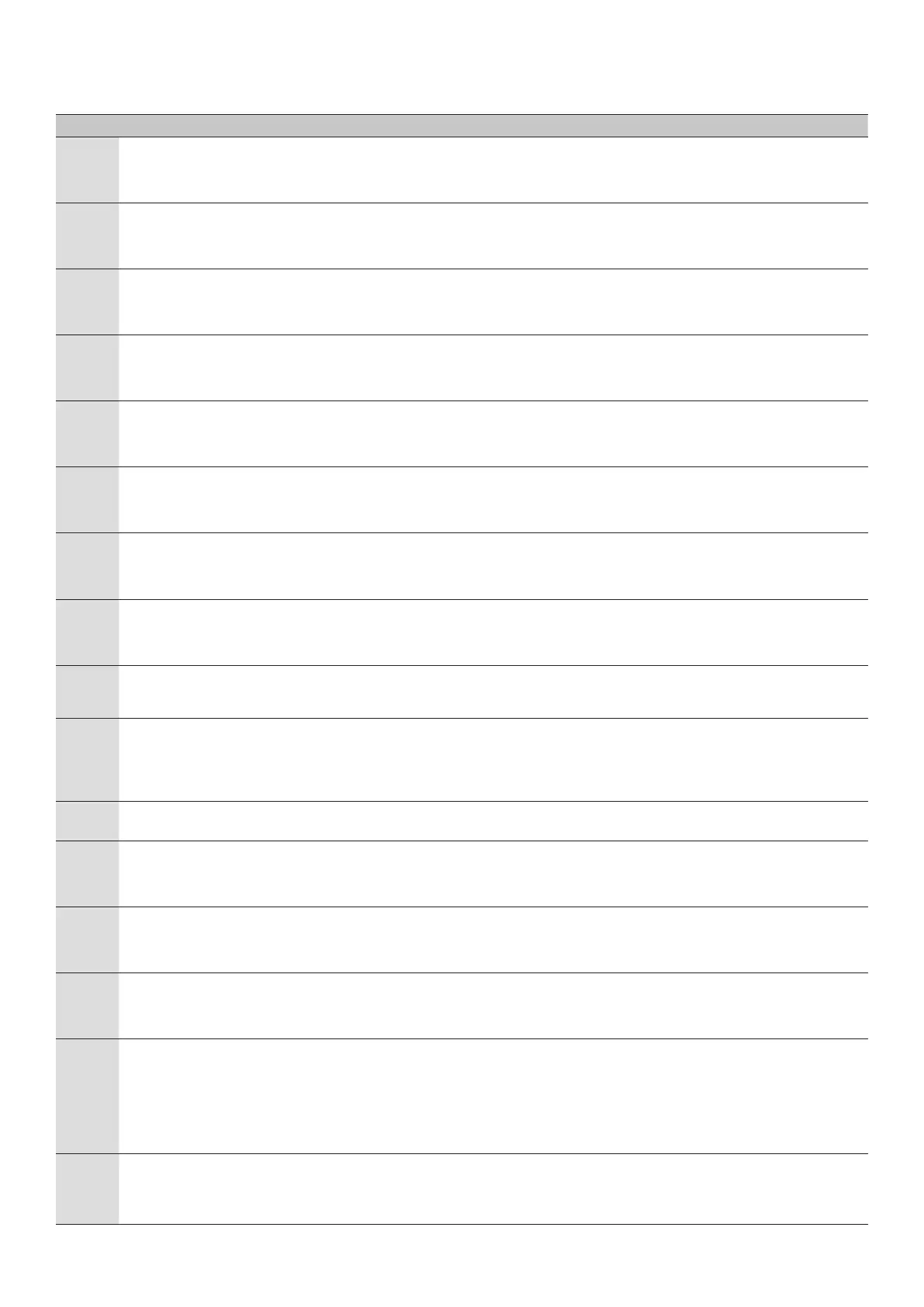

Display Malfunction Description Corrective Action

E0 Error of sensor T5U (upper water temperature sensor)

The connection between sensor and PCB is broken or the

sensor has experienced an issue.

Contact a qualified person to service the unit.

E1 Error of sensor T5L (lower water temperature sensor)

The connection between sensor and PCB is broken or the

sensor has experienced an issue.

Contact a qualified person to service the unit.

E2 Tank and wired controller communication error

The connection between controller and PCB is broken or the

PCB has experienced an issue.

Contact a qualified person to service the unit.

E4 Evaporator temperature sensor T3 error

The connection between sensor and PCB is broken or the

sensor has experienced an issue.

Contact a qualified person to service the unit.

E5 Ambient temperature sensor T4 error

The connection between sensor and PCB is broken or the

sensor has experienced an issue.

Contact a qualified person to service the unit.

E6 Compressor discharge temperature sensor TP error

The connection between sensor and PCB is broken or the

sensor has experienced an issue.

Contact a qualified person to service the unit.

E8

Electric leakage error. If PCB current_induction_circuit

check the current difference between L,N >14mA, system

consider it as “electric leakage error”

The connection between some wires have broken or there is

a wiring connection issue.

Contact a qualified person to service the unit.

E9 Compressor suction temperature sensor TH error

The connection between sensor and PCB is broken or the

sensor has experienced an issue.

Contact a qualified person to service the unit.

EE

E-heater open-circuit error

(IEH (Current difference E-heater on & E-heater off ) < 1A)

The E-heater has been broken or there is a wiring connection

issue. Contact a qualified person to service the unit.

EF Clock chip error

The chip has been broken. However the unit can continue to

operate without clock-memory, but the clock will need to be

reset every-time power to the unit is restarted. If necessary,

contact a qualified person to service the unit.

Ed E-EPROM chip error Contact a qualified person to service the unit.

P1

System high pressure protection

≥ 3.0MPa active ;≤ 2.4MPa inactive

Either the system is blocked, there is excessive air, water or

refrigerant in system, of the water temperature sensor has

malfunctioned. Contact a qualified person to service the unit.

P2

High discharge temperature protection

Tp>115°C, Protection active

Tp<90°C, Protection inactive

System is potentially blocked, air or water or low refrigerant

(leakage) in system or water temp sensor malfunction.

Contact a qualified person to service the unit.

P3

Compressor abnormally stopped. The discharge temp is

less than the evaporator temp after compressor has been

running for a period

Compressor is broken or there is a wiring connection issue

between the PCB and compressor.

Contact a qualified person to service the unit.

P4

Compressor overloaded protection (10 seconds after

compressor start up), Current checking starts,

1. Only when compressor is running, if it is >7A , the

compressor will stop for protection.

2. Compressor + e-heater open, if it is >IEH+7,the

compressor will stop for protection.

Compressor is broken, system blocked, air or water or too

much refrigerant in system or water temperature sensor

malfunction.

Contact a qualified person to service the unit.

LA

When the ambient temp T4 is out of Heat Pump running

range (-7 ~ 43°) Heat Pump will stop, unit will show LA on

the position of clock on display until T4 back to (-7 ~ 43°)

It is normal, and repair is not necessary.

NOTE: The diagnostic codes above are the most common. If any other diagnostic code is displayed, contact for technical assistance.

7.2 Error Codes

Loading...

Loading...