R410A All DC Inverter V4+S Series 60Hz MCAC-VTSM-2015-09

116 Installation

a. Inner side of pipeline

b. Inner side of pipeline + upright

c. Inner side of pipeline + upright+ outer side of pipeline

11. Vacuum Drying

11.1 Purpose and main points of vacuum drying

11.1.1 Purpose of vacuum drying

1. Remove moisture from the system to prevent ice-blockage and copperizing. Ice-blockage will cause

abnormal operation, while copperizing may damage compressor.

2. Eliminating the non-condensable gas of system prevents oxidizing of internal components, system pressure

fluctuation, and low heat exchange performance..

3. Detect leak source from reverse rotate.

11.1.2 Selection of vacuum pump

1. Vacuuming suction must be less than -14.6PSI(756mmHg).

2. The discharge of vacuum pump is over 4L/s.

3. The precision of vacuum pump is over 0.001ft.H2O(0. 02mmHg).

R410A system caution:

After the vacuuming process of R410A refrigerant circulation system is complete, vacuum pump will stop

running. As a result of suction in the in the air conditioning system, vacuum pump lubricant will seep back into

the system. This, same situation will also occur if vacuum pump suddenly stops during operation. This will

cause different oils mix, leading to system malfunction, it is therefore recommended to use one-way valve to

prevent reverse flow of oil in vacuum pump.

11.1.3 Vacuum drying for piping

Vacuum drying: Use of vacuum pump effectively transfers moisture in lines from liquid to gas state. Typical

boiling point for water is 212F(100C)the vacuum pump reduces the internal pressure of the piping system thus

reducing the boiling point of water to room temperature. This process evaporates all moisture in the piping

system.

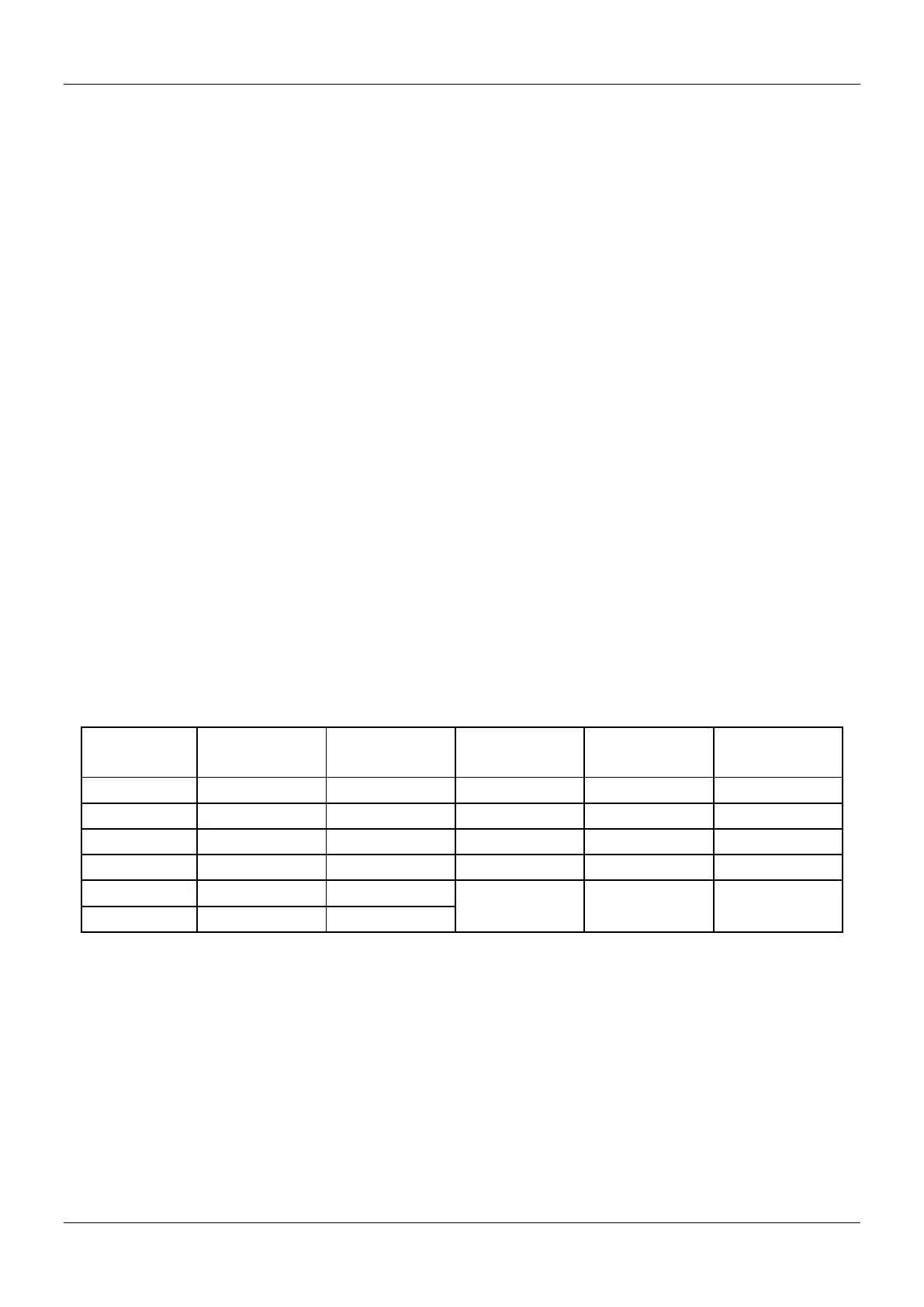

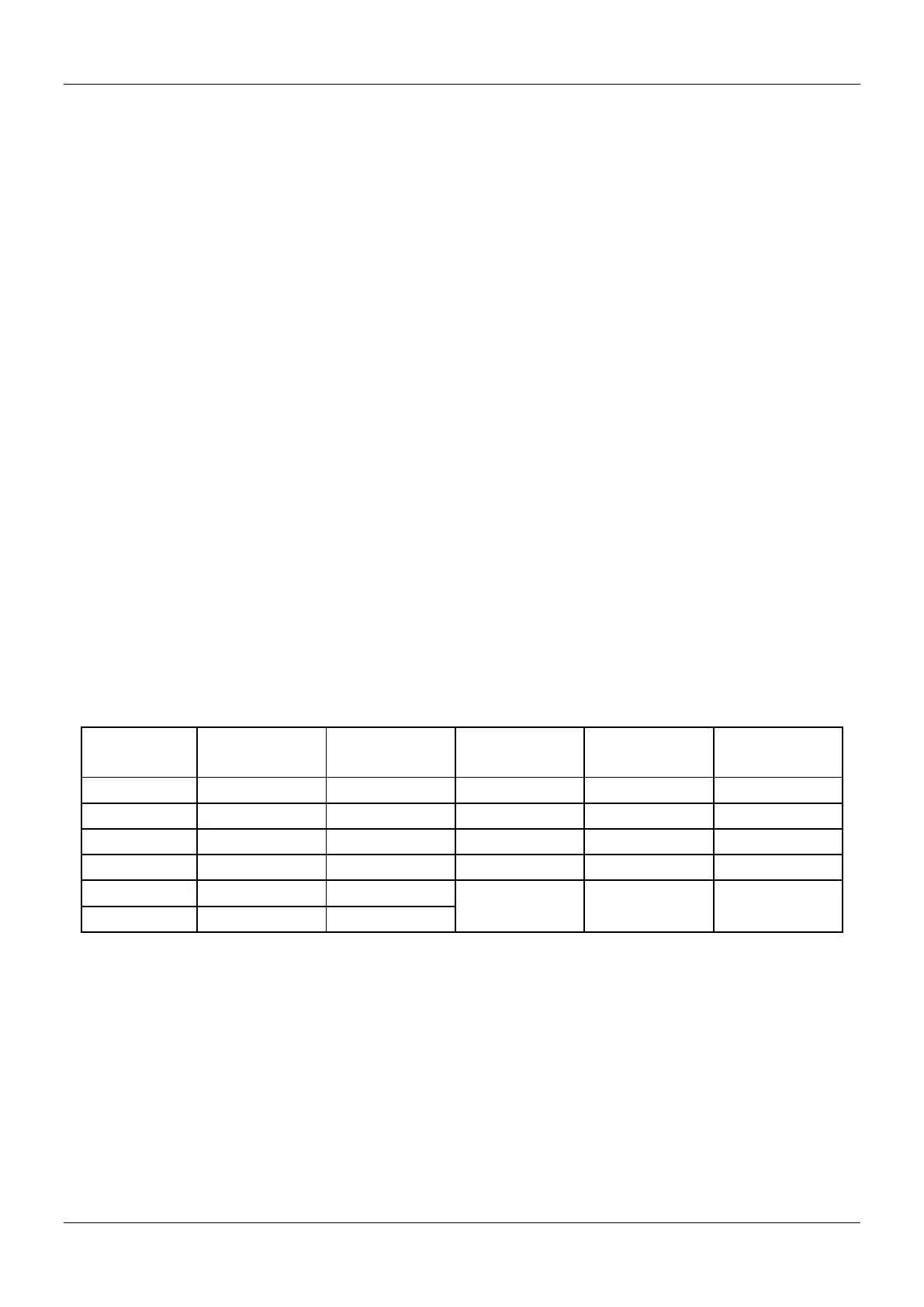

Boiling Point of

Water (°F(°C))

Vacuum Degree

(PSI(mmHg))

Boiling Point of

Water (°F(°C))

Vacuum Degree

(PSI(mmHg))

11.2 Operation procedure

There are two vacuum drying methods: common and special.

11.2.1 Ordinary vacuum drying

1) Connect the pressure gauge to the infusing mouth of gas and liquid pipe, keep vacuum pump running for at

least 2 hours, ensures vacuum degree o is below -14.6PSI(-755mmHg).

2) If the vacuum degree is not below -14.6PSI(-755mmHg) after 2 hours of drying, system will continue drying

for one hour.

3) If the vacuum degree is not be below -14.6PSI(-755mmHg) after 3 hours of drying, check the system for

leaks.

4) Vacuum placement test: when the vacuum degree reaches -14.6PSI(-755mmHg), keep for 1 hour. If the

vacuum gauge indicator does not increase, the process is complete. If the vacuum gauge increases, it

indicates of moisture or a leak.

Loading...

Loading...