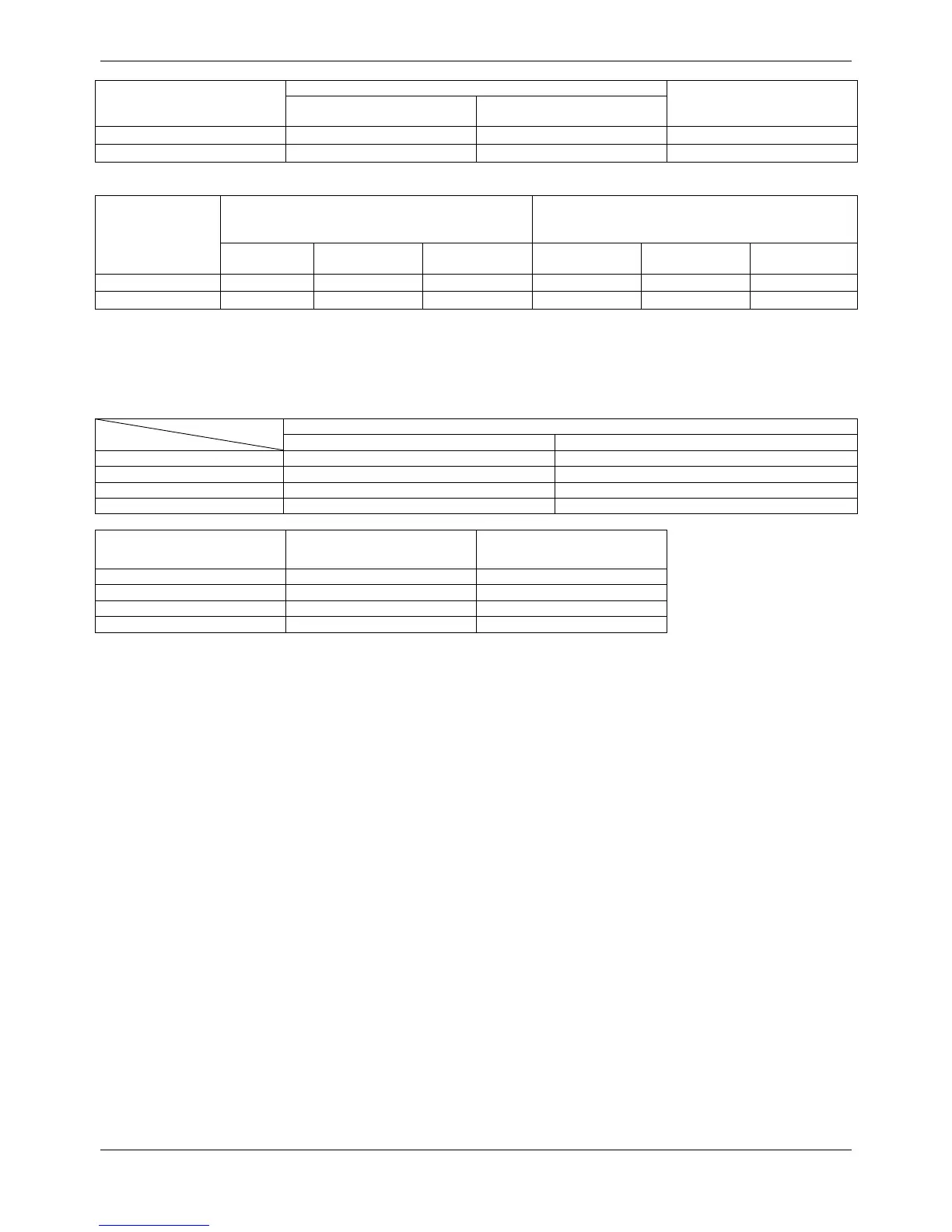

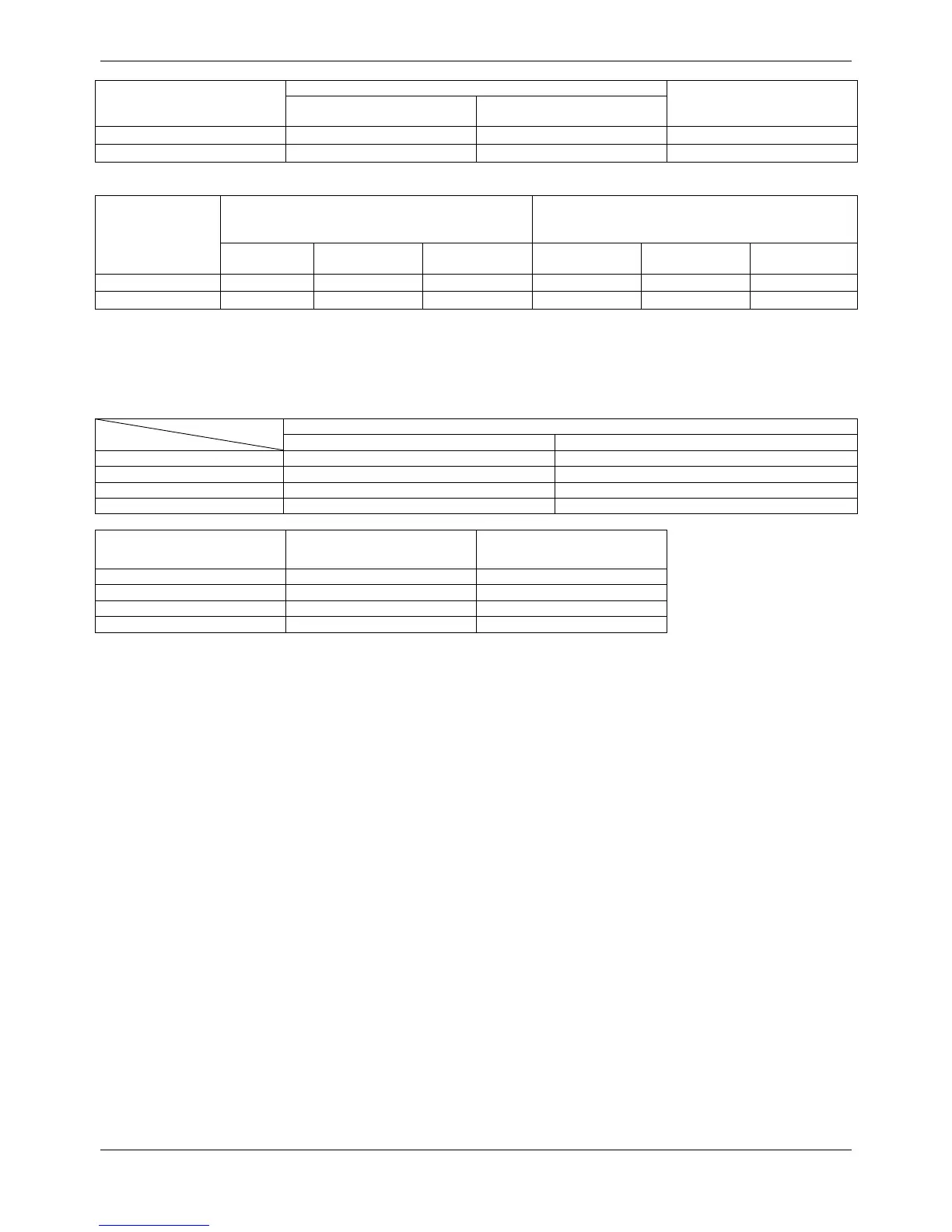

Note: Main pipe L1 can be selected form table 2 and table 3, the larger size should be finally selected.

The straight distance between copper pipe turning and the contiguous branch pipe is at least 0.5m;

The straight distance between the contiguous branch pipes is at least 0.5m;

The straight distance which the branch pipes connected to the indoor unit is at least 0.5m;

Table4: Outdoor unit pipe connection

If ODU connect only one IDU, the capacity of IDU should be not more than ODU.

If ODU connect more than one IDU, the capacity of each IDU should be not more than 8kW for refrigerant uniform distribution.

When capacity of indoor unit greater than the sum of 100%, capacity of indoor unit will be attenuated.

When capacity of indoor unit greater than or equal to the sum of 120%, in order to ensure the effectiveness of machine, and then

try to open the indoor units at different time.

When the capacity of indoor unit is greater than or equal to 16.8kW, the caliber of primary gas pipe should be augmented from

Φ16 to Φ19.

4.4 Remove Dirt or Water in the Piping

Make sure there is no any dirt or water before connecting the piping to the outdoor units.

Wash the piping with high pressure nitrogen, never use refrigerant of outdoor unit.

4.5 Airtight Test

Charge pressured nitrogen after connecting indoor/outdoor unit piping to do airtight test.

Cautions:

1. Pressured nitrogen [4.3MPa (44kg/cm) for R410A] should be used in the airtight test.

2. Tighten high pressure/low pressure valves before applying pressured nitrogen.

3. Apply pressure from air vent mouth on the high pressure/low pressure valves.

4. The high pressure/low pressure valves are closed when applying pressured nitrogen.

5. The airtight test should never be use any oxygen, flammable gas or poisonous gas.

4.6 Vacuum

Using vacuum pump to do the vacuum and never using refrigerant to expel the air.

Vacuum should be done from both liquid side and gas side simultaneously.

Loading...

Loading...