Installation detail

14

vacuum the indoor unit through the maintenance port on the cut-off valves, or open the

high-pressure valve, and exhaust the air through the maintenance port on the low-pressure

valve(closed). It will take about ten seconds. Then screw tightly the maintenance port. (When

supplement the refrigerant, fill through the maintenance port of the low-pressure valves on the

outdoor unit ).

e.

Open all the valves completely before power on the system, or it will be sick for low efficiency.

f.

Gas leak check. Make sure no gas from connections with leak detector or soap water.

6.3.2.2 Using bronze pipe selling in market

Completely shut the cut-off valves of the outdoor unit (as ex-work status). After the refrigerant

pipe has been connected with both the indoor and outdoor unit, let the air exhaust out from the

maintenance gap on he low-pressure cut-off valves of the outdoor unit. Screw the nuts tightly

on the maintenance gap after the air has been drained.

6.3.2.3 To make the refrigerant pipe unblocked completely

you should keep the cut-off valves of the outdoor unit completely open after you have finished

the above steps (step1) or step 2))

Note: Before screwing the reamer nut, smear the pipe and the connecting surface with

refrigerant oil; Check and make sure there is no leakage by soap-water or leakage-checker after

connecting;

Be sure the connecting joint on the indoor side is insulated.

Use two wrenches to connecting the pipes.

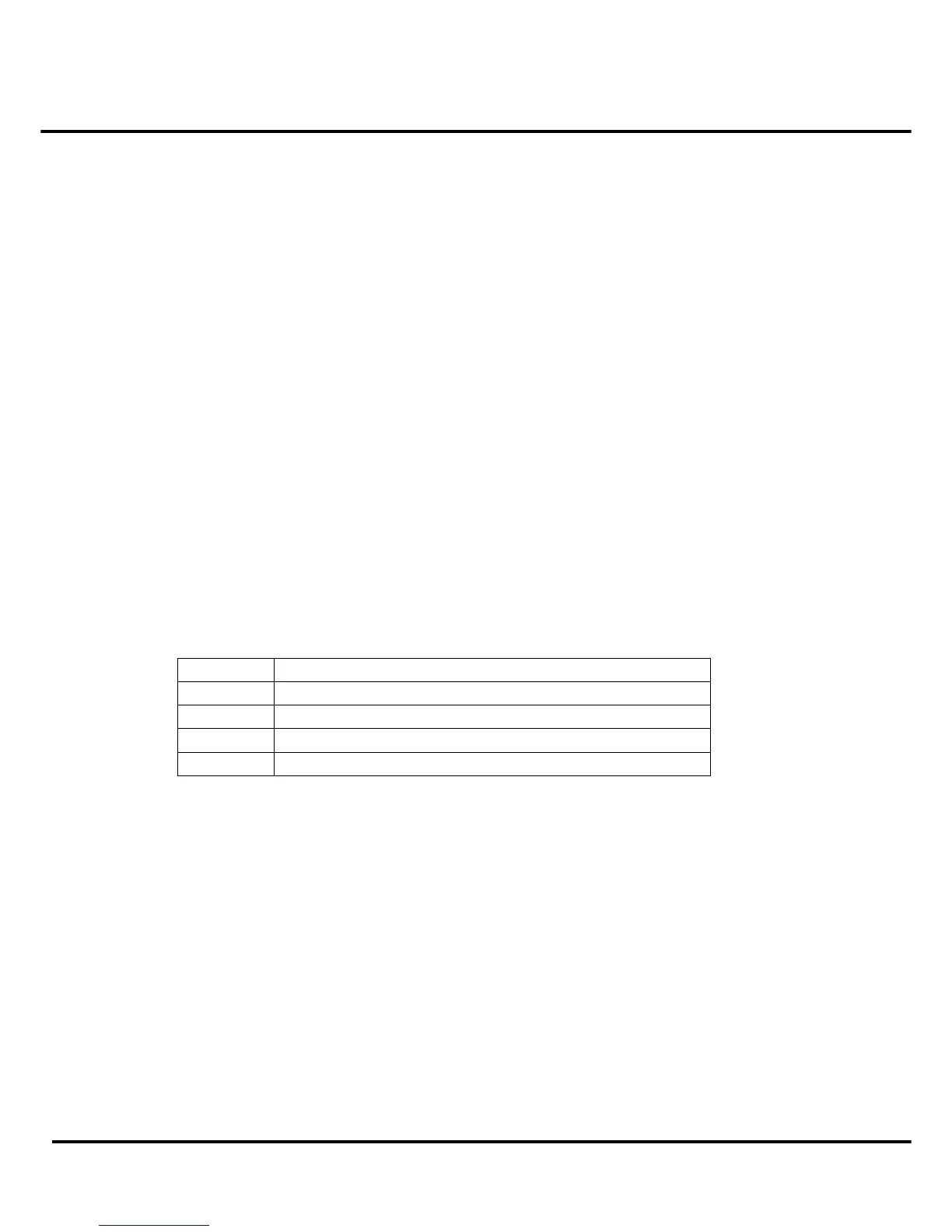

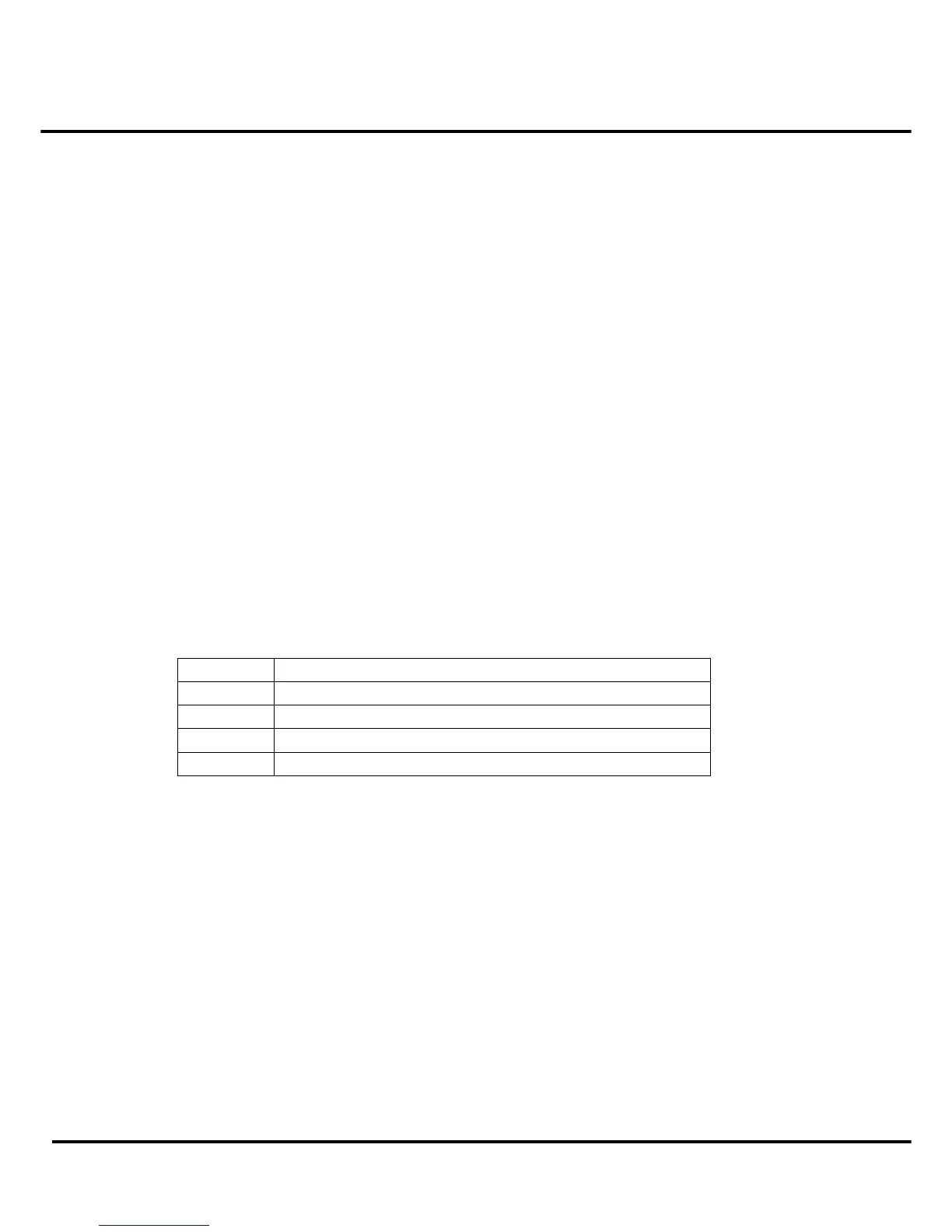

Tubing size Torque

9.52 3270~3990N.cm(333~407kgf.cm)

12.7 4950~6030N.cm(504~616kgf.cm)

16 6180~7540N.cm(630~770kgf.cm)

19 9720~11860N.cm(990~12106kgf.cm)

6.3.3 Air Purging

When Using the Vacuum Pump

(For method of using a manifold valve, refer to its operation manual.)

a.

Completely tighten the flare nuts, A, B, C, D, connect the manifold valve charge hose to a

charge port of the low-pressure valve on the gas pipe side.

b. Connect the charge hose connection to the vacuum pump.

c. Fully open the handle Lo of the manifold valve.

d. Operate the vacuum pump to evacuate. After starting evacuation, slightly loose the flare nut of

the Lo valve on the gas pipe side and check that the air is entering.(Operation noise of the

vacuum pump changes and a compound meter indicates 0 instead of minus)

e. After the evacuation is complete, fully close the handle Lo of the manifold valve and stop the

operation of the vacuum pump. Make evacuation for 15 minutes or more and check that the

compound meter indicates -76cmHg (-10x106Pa).

Loading...

Loading...