M thermal Mono

44 202005

Midea M thermal Mono Engineering Data Book

Hold the pipe end downwards when removing burrs

Cover the pipe end when inserting it through a wall to prevent dust and dirt entering.

Use a good thread sealant for sealing the connections. The sealing must be able to withstand the pressures and

temperatures of the system.

When using non-copper metallic piping, be sure to insulate the two kind of materials from each other to prevent

galvanic corrosion.

For copper is a soft material, use appropriate tools for connecting the water circuit. Inappropriate tools will cause

damage to the pipes

3.4 Water Circuit Anti-freeze Protection

Ice formation can cause damage to the hydronic system. As the outdoor unit may be exposed to sub-zero temperatures,

care must be taken to prevent freezing of the system. All internal hydronic parts are insulated to reduce heat loss.

Insulation must also be added to the field piping.

The software contains special functions using the heat pump to protect the entire system against freezing.

When the temperature of the water flow in the system drops to a certain value, the unit will heat the water, either

using the heat pump, the electric heating tap, or the backup heater. The freeze protection function will turn off only

when the temperature increases to a certain value.

In event of a power failure, the above features would not protect the unit from freezing.

Since a power failure could happen when the unit is unattended, the supplier recommends use anti-freeze fluid to

the water system or install freeze protection valves which can drain the water from the system before it can freeze.

Anti-freeze fluid

Depending on the expected lowest outdoor temperature, make sure the water system is filled with a concentration

of glycol as mentioned in the table below. If the system contains a domestic hot water tank, then only propylene

glycol is suitable. If the system does NOT contain a domestic hot water tank, then either propylene glycol or ethylene

glycol is OK. When glycol is added to the system, the performance of the unit will be affected. The correction factor

of the unit capacity, flow rate and pressure drop of the system is listed in the table 3-3.2 and 3-3.3.

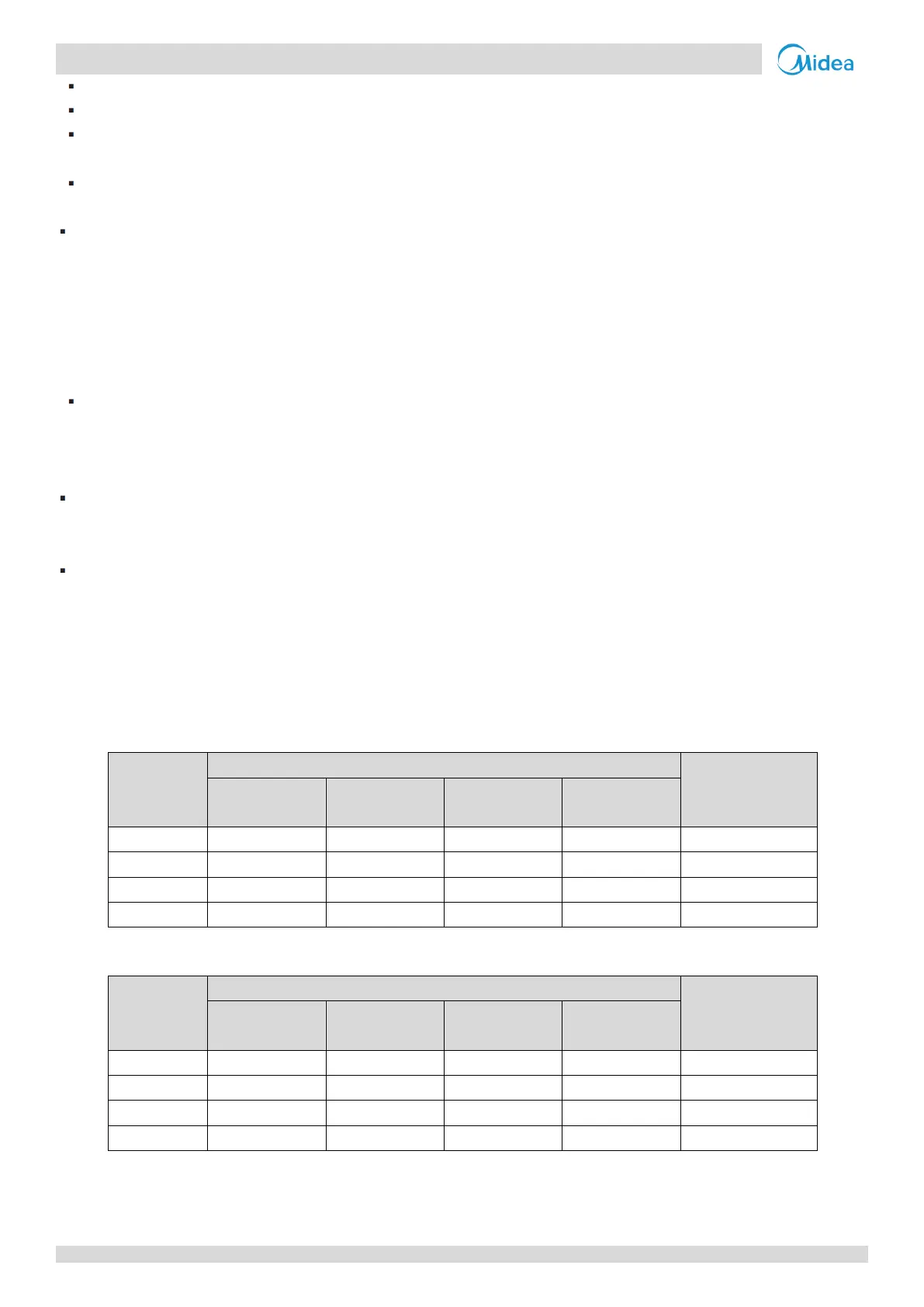

Table 3-3.2: Ethylene Glycol

Concentration

of ethylene

glycol (%)

Minimum outdoor

temperature(° C )

Cooling capacity

modification

Table 3-3.3: Propylene Glycol (including the necessary inhibitors, classified as Category III according to EN1717)

Concentration

of propylene

glycol (%)

Minimum outdoor

temperature (° C )

Cooling capacity

modification

Uninhibited glycol will turn acidic under the influence of oxygen. This process is accelerated by presence of copper

and at higher temperatures. The acidic uninhibited glycol attacks metal surfaces and forms galvanic corrosion cells

that cause severe damage to the system. It is of extreme importance:

Loading...

Loading...