14

EC DECLARATION OF CONFORMITY

MIGATRONIC A/S

Aggersundvej 33

9690 Fjerritslev

Denmark

hereby declare that our machine as stated below

Type: AUTOMIG

conforms to directives: 2014/35/EU

2014/30/EU

2011/65/EU

European standards: EN/IEC60974-1

EN/IEC60974-5

EN/IEC60974-10 (Class A)

Issued in Fjerritslev 17.05.2017

Niels Jørn Jakobsen

CEO

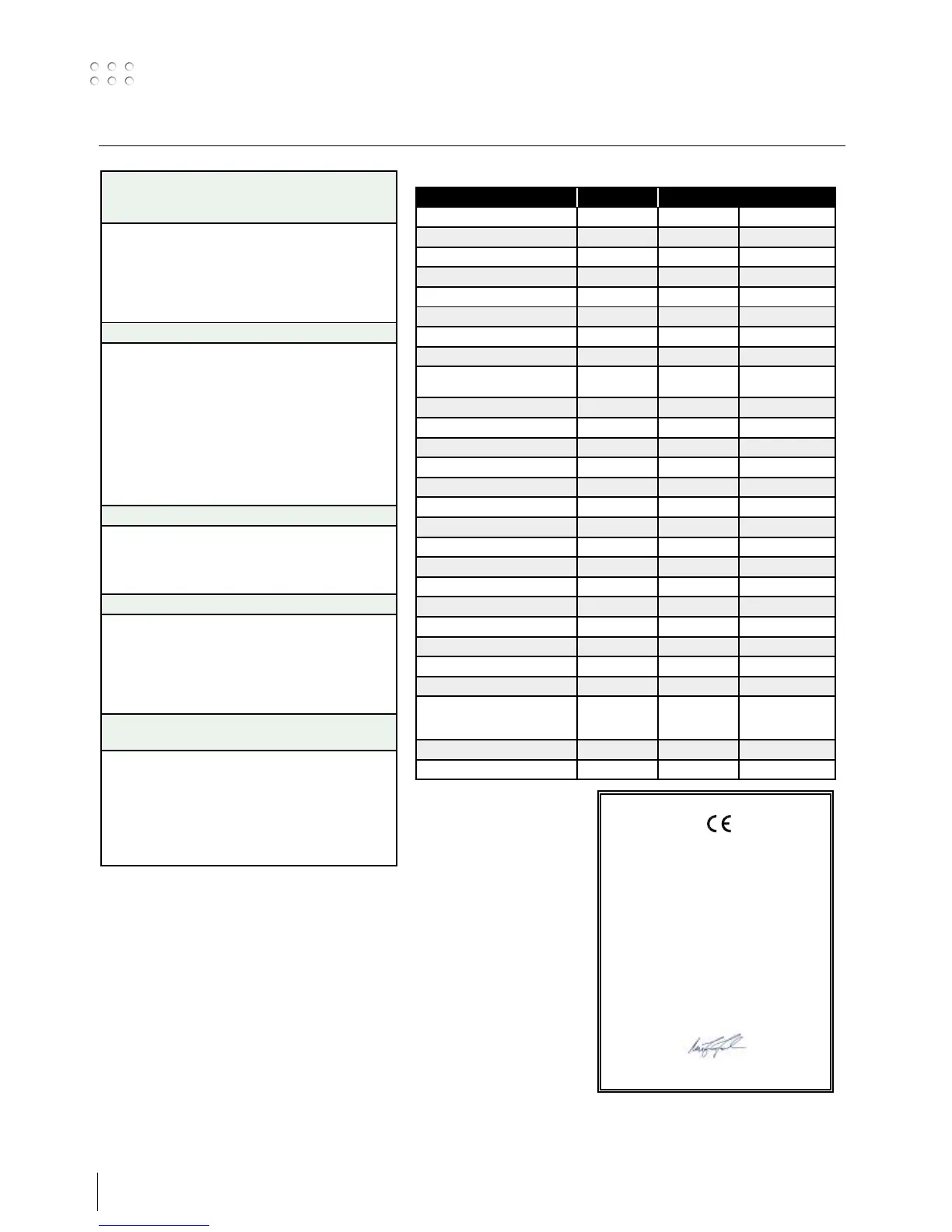

TYPE Automig 183 Automig 223 Automig 273

Current range, A 20-180 20-200 20-250

Minimum generator size, kVA 6 8 10

Voltage steps 7 10 10

Duty cycle 100% 40°C, A/V 65/17.3 105/19.3 140/21.0

Duty cycle, 60% 40°C, A/V 85/18.3 125/20.3 165/22.0

Duty cycle, 35% 40°C, A/V 110/19.5 150/21.5 200/24.0

Duty cycle, 30% 40°C, A/V - 155/21.8 -

Open circuit voltage, V 14-30 14-30 15-34

1

Mains voltage±15%, V 3x400 (3x230) 3x400

(3x200/3X230)

3x400/500

(3x200/230)

Fuse, A 10 10 10

Mains current, effective, A 2.5 (4.4) 4.0 (8.0/7.0) 5.9/4.7 (11.8/10.3)

Mains current, max., A 5.7 (9.9) 7.3 (14.6/12.7) 10.0/8.0 (20.0/17.4)

Power, 100%, kVA 1.8 2.8 4.1

Power, max., kVA 4.1 5.1 6.9

Power, open circuit, W <10 <10 <10

Power factor 0.85 0.85 0.85

Wire dimension, mm 0.6-1.0 0.6-1.2 0.6-1.2

Wire reel capacity, kg 5-15 5-15 5-15

Wire speed, m/min 2-12 2-14 2-15

1

Spot welding time, s 0.15-2.5 0.15-2.5 0.15-2.5

2

Stitch welding time, s 0.15-2.5 0.15-2.5 0.15-2.5

Burn back, s 0.05-0.5 0.05-0.5 0.05-0.5

3

Application class S S S

4

Protection class IP21 IP21 IP21

Standards EN/IEC60974-1.

EN/IEC60974-5.

EN/IEC60974-10

EN/IEC60974-1.

EN/IEC60974-5.

EN/IEC60974-10

EN/IEC60974-1.

EN/IEC60974-5.

EN/IEC60974-10

Dimensions, HxWxL, mm 700x380x720 700x380x720 700x380x720

Weight, kg 57 64 66

1) Delivery for other mains voltages is possible

2) The functions 4-times, spot and stitch welding can only be found on some machine versions

3) Meets the demands made for machines which are to operate under special working conditions

4) This machine is designed for indoor operation and meets the requirements of protection class IP21

Troubleshooting and solution / Technical data

We reserve the right to changes

Too little welding effect.

The welding seam forms a bead standing proud of

the plate

1. One of the three fuses in the main switch is not

working. (This applies to three-phase machines

only).

2. The welding voltage is too low.

Switch one setting higher.

The wire feed is blocking

1. The inlet nozzle and the wire are not in

alignment with each other.

2. The reel of wire is too taut, the wire must come

off the reel evenly.

3. The inlet or contact tip has worn out or is

blocked up.

4. The welding wire is not clean or it is rusty. It

could also be of an inferior quality.

5. The pressure roller has to be tightened.

Spatter

1. The wire feed is too fast for the voltage setting.

2. Worn out contact tip.

Porous weld. A cone is formed when spot welding

1. Insufficient gas - too little pressure or the bottle

is empty.

2. Contact tip is blocked up.

3. Leakage air is pumped in and mixes with the

shielding gas.

The wire keeps sticking in the contact tip and feeds

at slow speed

1. The damaged wire should be cut off, pulled

out and replaced. The pressure on the wire

feed roller should be checked and adjusted if

necessary.

2. Worn out contact tip.

3. Wire feed speed may need increasing.

Loading...

Loading...