18

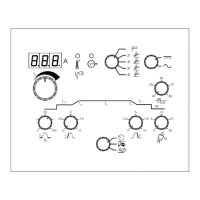

Mains error

The mains error indicator is illuminated if the mains

voltage is too high or low. The indicator remains

illuminated 5 seconds after the mains error is

corrected/removed.

Welding process

This display is used to select

the welding process, e.g. MMA electrode or TIG.

The function is fixed during welding, and shift from

TIG to MMA is not possible before the post-flow

has been finished.

MMA electrode

MMA electrode welding has been selected.

TIG

TIG welding has been selected.

Function of the torch trigger

(The trigger method)

This display is used to decide whether the start/stop

method of the TIG welding process is to be two-

times, four-times (latching), or spot. Welding

process means the phases: pre-flow, slope-up,

welding with adjusted current, if necessary, reduced

current, slope-down and post-flow. It is not possible

to change trigger method during the welding

process.

Two-times

The welding process begins by pressing the torch

trigger. Welding continues until the trigger is re-

leased again which effects the slope-down period.

Four-times

The welding process begins by pressing the torch

trigger. Releasing the torch trigger during gas pre-

flow activates the slope-up period. If the torch

trigger is released during the slope-up period

welding continues with the adjusted welding current.

In order to stop the welding process the trigger

must be pressed again after which the slope-down

period begins. The slope-down period can be

stopped by releasing the trigger.

Set we lding

current

slope-up

slope-down

trig down ( ) / up ( )

time

mp

Spot

The welding process begins by pressing the torch

trigger. Welding stops automatically, depending on

the time set in spot time.

Amp setting function

The AMP keypad is used to

select the method by which the required welding

current shall be established. This welding current is

then shown in the display and cannot be changed

during the welding process.

Internal adjustment

The control knob positioned below the digital

display is used to set the current.

External adjustment

Current setting to be by means of a

Migatronic remote control unit. The remote control

unit is connected to a plug positioned on the rear of

the machine (not standard equipment).

Torch adjustment

Current setting to be by means of the current

control knob located in the handle of a Migatronic

dialog torch, if a dialog torch is used. The maximum

current is set with the control knob on the front

panel. The torch control is used to reduce the

current from the maximum set current to the

minimum current.

Ignition of TIG welding

It is possible to choose be-

tween two different methods of ignition for TIG

welding: High-frequency (HF) and LIFTIG ignition.

The method of ignition cannot be changed during the

welding process.

Two-stroke

This symbol means contact-free striking.

The arc is established in the following way:

1) The torch is placed so that the Tungsten elec-

trode is quite close to the welding spot (1 or 2

mm).

2) The torch trigger is activated, and the high

voltage generator of the machine will produce a

voltage impulse that ignites the arc. The welding

process has started. The welding process will

stop when the torch trigger is deactivated. The

arc will extinguish after the period of slope-down

time. The torch is held at the welding spot until

after the period of gas post-flow time in order to

protect the welding spot against oxidation.

Four-stroke

This symbol means contact-free striking.

The arc is established in the following way:

1) The torch is placed so that the Tungsten elec-

trode is quite close to the welding spot (1 or 2

mm).

2) The torch trigger is activated, and the high

voltage generator of the machine will produce a

voltage impulse that ignites the arc. The torch

trigger is deactivated. The welding process will

stop when the torch trigger is reactivated.

Loading...

Loading...