17

INITIAL INSTRUCTIONS

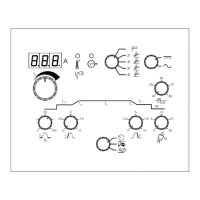

All "parameters" are set by the use of only one

control knob. These parameters include current,

pulse time, slope-up time, etc.

This control knob is positioned below a digital

display which shows the value of the parameter

being set. The unit of measurement of the para-

meter is shown at the right hand side of the digital

display.

As above, selection of a function, e.g. HF-TIG or

LIFTIG, is by means of the keypad in the relevant

section. The function selected is indicated by a

bright indication light.

Storage of parameters

The machine memorises all settings when the mains

input voltage is switced off, thus ensuring that the

same machine settings are available when the

machine is switched on again.

The exact adjustments in the two welding processes

(MMA electrode and TIG) are stored as well, so

that shifting from one welding process to another

does not require a new current setting.

Setting of the machine

The following describes in detail the operation of the

machine.

Welding current

On pressing this keypad the control knob can

be used to set the welding current unless however

that, the machine has been set to external

adjustment. After the welding process has stopped,

the adjusted current is shown on the display, during

welding, however, the actual welding current is

shown.

During pulse welding an average welding current is

automatically shown when shifting between welding

current and base current becomes faster than

possible viewing.

Setting of welding jobs

This function enables storage of often used

machine settings and shift from one complete

setting to another. By pressing the keypad the

display shows a "P" and a number: "1", "2" etc.

Each number is a setting of all parameters and

functions of the machine. It is therefore possible to

have one setting for each welding job for which the

machine is used. The control knob is used for

shifting between these settings. During shifting it is

possible to see both process and the other on/off-

functions in each setting. Change of setting is not

possible during the welding process. The setting

selected is effected by releasing the keypad.

Welding voltage

The welding voltage indicator is illuminated for

reasons of safety and in order to show if there is

voltage on the electrode or the TIG torch.

Units of measurement of the parameter

Units of measurement of the parameter

shown in the digital display.

Overheating

The overheating indicator is illuminated if weld-

ing is interrupted due to overheating of the machine.

The indicator remains illuminated 5 seconds after

the overheating error is removed. Please read

chapter conc. "fault indification".

Loading...

Loading...