Do you have a question about the Migatronic PILOT 2400 and is the answer not in the manual?

Essential safety guidelines regarding electricity during welding operations.

Protective measures against eye and skin damage from arc emissions.

Health risks from inhaling welding fumes and necessary ventilation.

Steps to mitigate fire risks caused by welding sparks and radiation.

Instructions for connecting the welding machine to the main power supply.

Correct method for connecting welding cables and return current cable.

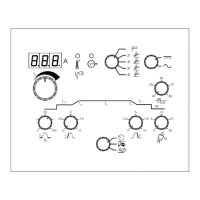

Using the control knob to set various welding parameters shown on the display.

Setting and displaying the welding current, with differences during and after welding.

Meaning of the overheating indicator and actions to take.

Indication of mains voltage issues (too high or too low).

Selecting the welding process, such as MMA electrode or TIG.

Deciding the start/stop method for TIG welding: two-times, four-times, or spot.

Selecting the method for establishing the required welding current.

Choosing between High-frequency (HF) and LIFTIG ignition methods.

Contact-free striking using HF ignition, arc starts with trigger, stops on release.

Contact-free striking using HF ignition, arc starts with trigger, stops on reactivation.

LIFTIG ignition method, arc starts by lifting torch, stops on trigger deactivation.

Interruption due to overheating and required cooling actions.

| Output Current Range | 5-240 A |

|---|---|

| Weight | 15.5 kg |

| Mains frequency | 50 / 60 Hz |

| Current range | 5-240 A |

| Protection class | IP23 |

| Enclosure class | IP23 |

| Current Range (TIG) | 5-240 A |

| Standard | EN/IEC 60974-1 |

| Welding Process | TIG / MMA |

| Max. Output | 240 A |

Loading...

Loading...