20

However, after slope-down the machine does not

switch directly to post-flow but to pilot arc again. It

is now possible to continue with a new welding pro-

cess by a lengthy activation of the torch trigger (>

0.3 seconds), or to extinguish the pilot arc by a brief

activation (< 0.3 seconds) of the torch trigger.

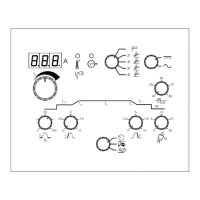

The welding process

for TIG welding

The parameters can be

both selected and ad-

justed during welding

Pre-flow

Pre-flow is the period of time for which gas flows

after the torch switch is pressed and before the HF

arc is established, or until the torch is lifted away

from the workpiece in the LIFTIG process. Variable

0-60 secs.

Start Amp

Immediately after the arc has been

established, the machine regulates the welding cur-

rent to the value stated in the Start Amp parameter.

Start Amp is set as a percentage of the required

welding current and is variable between 0-100% of

the welding current with a minimum value of 5 A.

Slope-up

Once the arc has been established, the wel-

ding process enters a slope-up stage during which

the welding current is increased in linear fashion

from the value stated in the Start Amp parameter to

the required welding current. The duration of this

slope-up time is variable 0-10 secs.

Slope-down

When welding has stopped by activating the

trigger, the machine enters a slope-down stage.

During this stage current is reduced from welding

current to Stop Amp over a period of time called the

slope-down time and variable 0-10 secs.

Stop Amp

The slope-down stage is completed when

the current level has fallen to the value stated in the

Stop Amp parameter. Stop Amp is stated as a per-

centage of the required welding current and is

variable between 0-100% of the welding current

with a minimum value of 5 A.

Post-flow

Post-flow is the period of time for which gas

flows after the arc is extinguished and is variable 3-

20 secs.

Loading...

Loading...