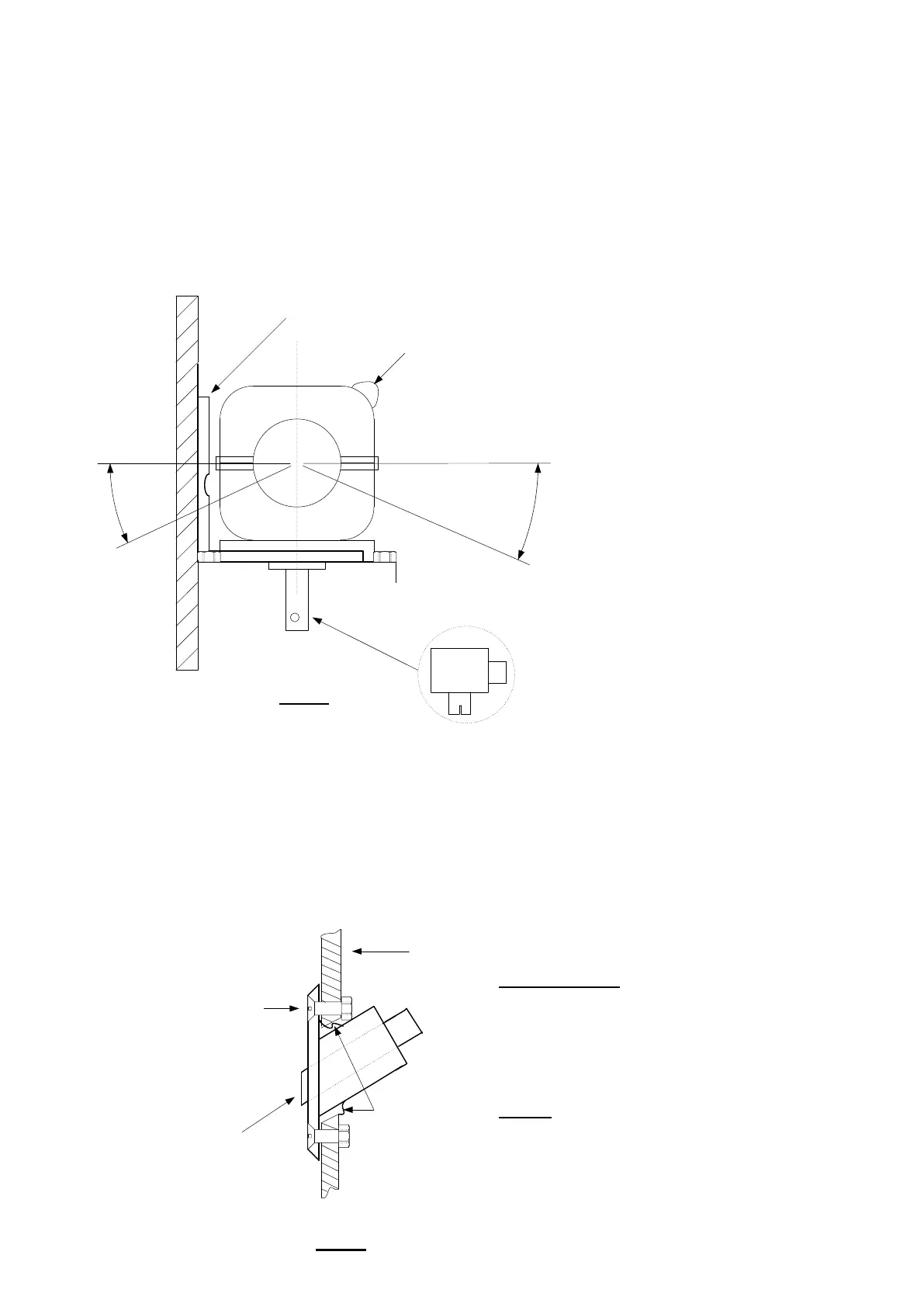

The heater is supplied with a stainless

steel

'L

'

shaped mounting bracket which is

designed to be fitted on a vertical

bulkhead with the heater sat in it

(

see dia

1

.)

The heater has to be mounted in this

way for correct operation

.

22

0

22

o

Examine the chosen mounting place

carefully to make sure that it has enough

strength to support the heater and that it is

free from excessive vibration while the

boat is in use

.

MY

16

:

Fix the mounting bracket to the bulkhead

using the

4

x

3/4

"

No

10

self tapping

screws provided

.

The heater can now be

fitted in place either way round

(

whichever

is the most convenient for the ducting run

)

with the

4

x s

/

s M

6

x

20

set screws

provided

.

MY

30

:

Fix the mounting bracket to the bulkhead

using the

6

x

3/4

"

No

10

self tapping

screws provided and mount the heater

using the

4

x s

/

s M

8

x

20

set screws

.

Now screw the s

/

s exhaust stub into the

bottom of the heat exchanger

,

and slide

the combustion air manifold

'A

'

over the

top

.

1.

Mounting the heater

.

The heater should be mounted in a well ventilated locker which should be dry and within

2

metres of a suitable site

for the exhaust skin fitting

.

It should also give consideration to servicing and access to cleaning the glow plug

.

The

heater should be mounted in such a way that the axis through the hot air outlet and fresh air inlet is horizontal

.

Bulkhead

s/

s exhaust stub

.

s/

s mounting bracket

glow plug

Permissible inclination angles

.

Dia

1.

2

.

Exhaust and combustion air system

:

The exhaust skin fitting needs to be fitted as far above the water line as possible to prevent any ingress of water into

the

heater

.

An ideal place for the skin fitting is on the transom

.

Once you have planned the siting

,

drill a

4

mm pilot hole as guidance for the pilot drill on the hole saw arbour

.

Now

drill the correct size hole

:

MY

16/

MY

30

=

42

mm

.

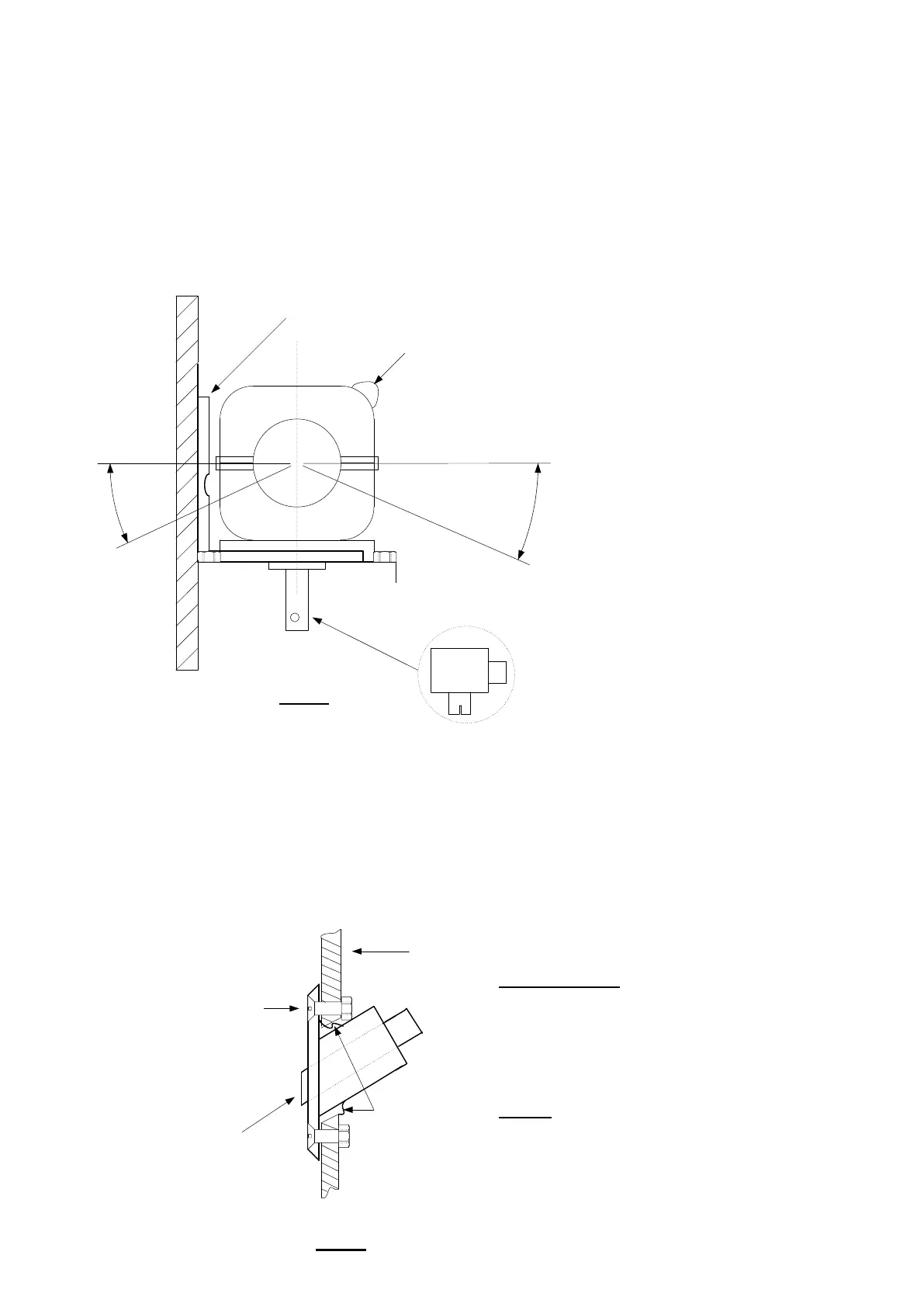

When you have completed this re

-

drill the hole at an angle at a slow

speed

(

see dia

2

)

to allow the skin fitting to fit in a snug hole

.

Now drill

4

x

5

mm holes for the fixing bolts

,

apply

silicon to the rear of the face and secure in place with the

4

x M

5

x

40

button head s

/

s screws provided

.

Drill with hole saw at angle

after you have drilled the

perpendicular hole

.

BE CAREFUL

!

Transom

4

x fixing screws

Dia

2.

Fix the s

/

s exhaust to the skin fitting and secure with

the heavy duty clamp

.

Cut the exhaust at a

convenient place to insert the silencer

,

(

MY

30

Only

)

and secure with a tridon hose clip

.

IMPORTANT TIP

: (

MY

30

Only

.)

Put an exhaust clamp

on one end of the remaining exhaust

,

now take the

combustion air manifold and insert the split spigot into

the end

.

Push this assembly onto the exhaust spigot

of the heater making sure that it slides home over the

heat exchanger casting

,

and tighten the clamp

.

The MY

16

does not require an exhaust silencer

.

NOTE

:

THE EXHAUST DOES GET HOT

-

DO NOT

CLAMP IT TO ANY COMBUSTIBLE MATERIALS

.

The exhaust lagging should now be wrapped around

the full length of the exhaust pipe and secured at each

end with the hose clips supplied

.

Silicon sealant

-

2

-

'A'

Loading...

Loading...