Do you have a question about the Miller Electric SCP-200C and is the answer not in the manual?

Overview of safety practices and their importance in welding operations.

Essential precautions for preventing burns, toxic fumes, and fire hazards.

Safety guidelines and precautions specific to arc welding procedures.

List of industry standards and references for welding safety.

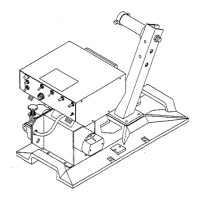

Provides context and purpose of the manual for personnel familiarization.

Instructions for inspecting and handling the equipment upon receipt.

Details about the single-phase welding power source and its intended use.

Highlights the importance of reading safety sections before operation.

Guidelines for selecting an appropriate installation site for the welding power source.

Detailed steps for making safe and correct electrical input connections.

Procedure for connecting welding cables to output terminals for optimal performance.

Instructions for connecting to the 115 VAC auxiliary power outlet.

Connecting a remote control station for contactor operation.

Describes the function and operation of the main power switch.

How to adjust the open-circuit voltage using the Voltage Control knob.

Explanation of the indicator displaying the selected open-circuit voltage.

Details on the receptacle for remote contactor control connections.

How to adjust the arc stabilizer for desired performance.

Understanding the welding power source's duty cycle and its importance.

Interpreting the volt-ampere curve for output voltage and current characteristics.

Step-by-step procedure for performing Gas Metal-Arc Welding.

Proper procedures for safely shutting down the welding power source.

Information regarding the fan motor and its maintenance requirements.

Recommendations for cleaning the transformer to ensure proper cooling.

Guidance on cleaning the rectifier for optimal cooling performance.

Details on fuses protecting the control circuit and the 115 VAC receptacle.

| Brand | Miller Electric |

|---|---|

| Model | SCP-200C |

| Category | Welding System |

| Language | English |