cover 7/93 – ST-155 507-A PRINTED IN USA

1997 MILLER Electric Mfg. Co.

Read and follow these instructions and all

safety blocks carefully.

Have only trained and qualified persons

install, operate, or service this unit.

Call your distributor if you do not understand

the directions.

Give this manual to the operator.

For help, call your distributor

or: MILLER ELECTRIC Mfg. Co., P.O. Box

1079, Appleton, WI 54912 414-734-9821

OWNER’S

MANUAL

October 1997 Form: OM-174 470B

Effective With Serial No. KH531011

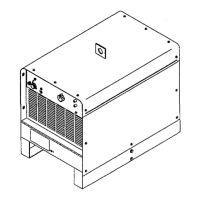

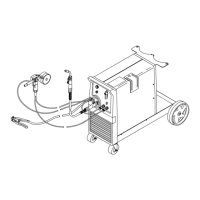

Gold Seal Model 420

CV/DC Welding Power Source/Wire Feeder

For FCAW And GMAW Welding

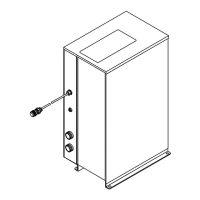

90 Amperes, 18 Volts At 20% Duty Cycle

Uses 115 Volts AC, Single-Phase Input Power

Overheating, Short-Circuit, And Motor Overload Protection

Usable Range Of 30 To 130 Amperes

Includes Gun, Welding Wire, And Gas Valve