Do you have a question about the Miller Spectrum 2050 and is the answer not in the manual?

Explains hazard symbols and general safety rules for operating the plasma cutter.

Covers electrical shock, fire, explosion, sparks, fumes, and arc rays during plasma cutting operations.

Addresses risks from exploding parts, flying sparks, arc rays, noise, fumes, plasma arc, and gas cylinders.

Details hazards related to installation, EMF, falling equipment, interference, and specific warnings.

Covers California Proposition 65 warnings, principal safety standards, and EMF information.

Explains symbols and their meanings found on the equipment's nameplate and rating label.

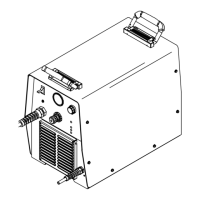

Covers unit specifications, location selection, and serial number identification for proper setup.

Explains duty cycle, overheating, and cutting speed guidelines for optimal operation.

Indicates serial number location and provides guidance on selecting an operating location.

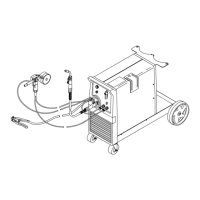

Details electrical service requirements, work clamp, gas/air supply, and fuse ratings for setup.

Provides data on recommended extension cord sizes and maximum lengths based on input voltage and phase.

Illustrates how to safely connect the input power to the plasma cutter, including grounding procedures.

Explains how to wire an optional 240 Volt plug for connecting to auxiliary power sources.

Details how to connect and set up the plasma cutter when using a generator as a power source.

Continues guidance on generator connection and control settings for specific Miller models.

Further instructions on generator connection and control settings for different Miller models like Trailblazer.

Identifies and describes the main controls on the plasma cutter, including pressure, output, and pilot arc settings.

Guides the user on how to set the correct gas/air pressure for optimal cutting performance.

Refers to wiring and control settings for powering the unit with a generator.

Provides a step-by-step guide for performing a typical plasma cutting operation.

Outlines a schedule for checking, changing, and cleaning various parts for regular maintenance.

Explains the function of the pressure, cup, and temperature trouble lights and their troubleshooting meanings.

Describes how to check the shield cup shutdown system and its proper function.

Details the procedure for checking and replacing the torch tip, electrode, retaining cup, and other parts.

Lists common problems, their causes, and recommended remedies for troubleshooting the unit.

Presents the main circuit diagram for the plasma cutting power source.

Shows detailed internal circuit diagrams including control, driver, and torch connections.

Lists and illustrates the main assembly components of the plasma cutter with part numbers.

Provides a detailed list of parts for the main assembly, including quantities and descriptions.

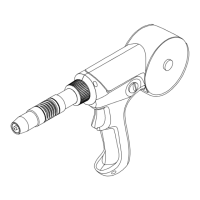

Lists and illustrates the parts for the torch assembly, including part numbers.

Details consumable parts for the torch, such as tips, electrodes, and shields, with part numbers.

Outlines the terms and conditions of the limited warranty, including coverage periods and exclusions.

Provides space for recording model name, serial number, purchase date, and distributor information.

Instructs on how to contact distributors or service agencies for parts, repair, and training.

| Input Voltage | 208/230/460 V |

|---|---|

| Weight | 70 lbs (31.8 kg) |

| Dimensions | 20.5 in. x 12.5 in. x 13.5 in. |

| Duty Cycle | 60% at 55 Amps |

| Input Phase | 1-Phase |

| Input Hz | 50/60 Hz |

| Input Power | 208/230/460 V |

| Processes | Plasma Cutting |