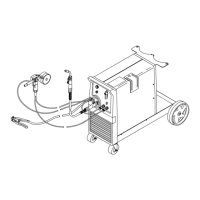

Why does the arc go out while cutting with my Miller Welding System?

- JJason WhitakerSep 9, 2025

The arc may go out while cutting due to several reasons: * Ensure the work clamp is securely attached to a clean, paint-free, rust-free workpiece. * Make sure the drag shield is on the workpiece or the extended tip is 1/8 in. (3.2 mm) from workpiece while cutting. * If working with thin metal, maintain a constant travel speed. * Verify that the compressed air is clean, dry, and oil-free, using filter kit 300491 or 228926 if necessary. * Check the retaining cup, ensuring it is hand-tightened only and not over-tightened. * Clean or replace worn consumables.