. A complete Parts List is available at www.MillerWelds.com

OM-264259 Page 26

Ref. 803 640-A / 801 400-B / Ref. 254 087-A

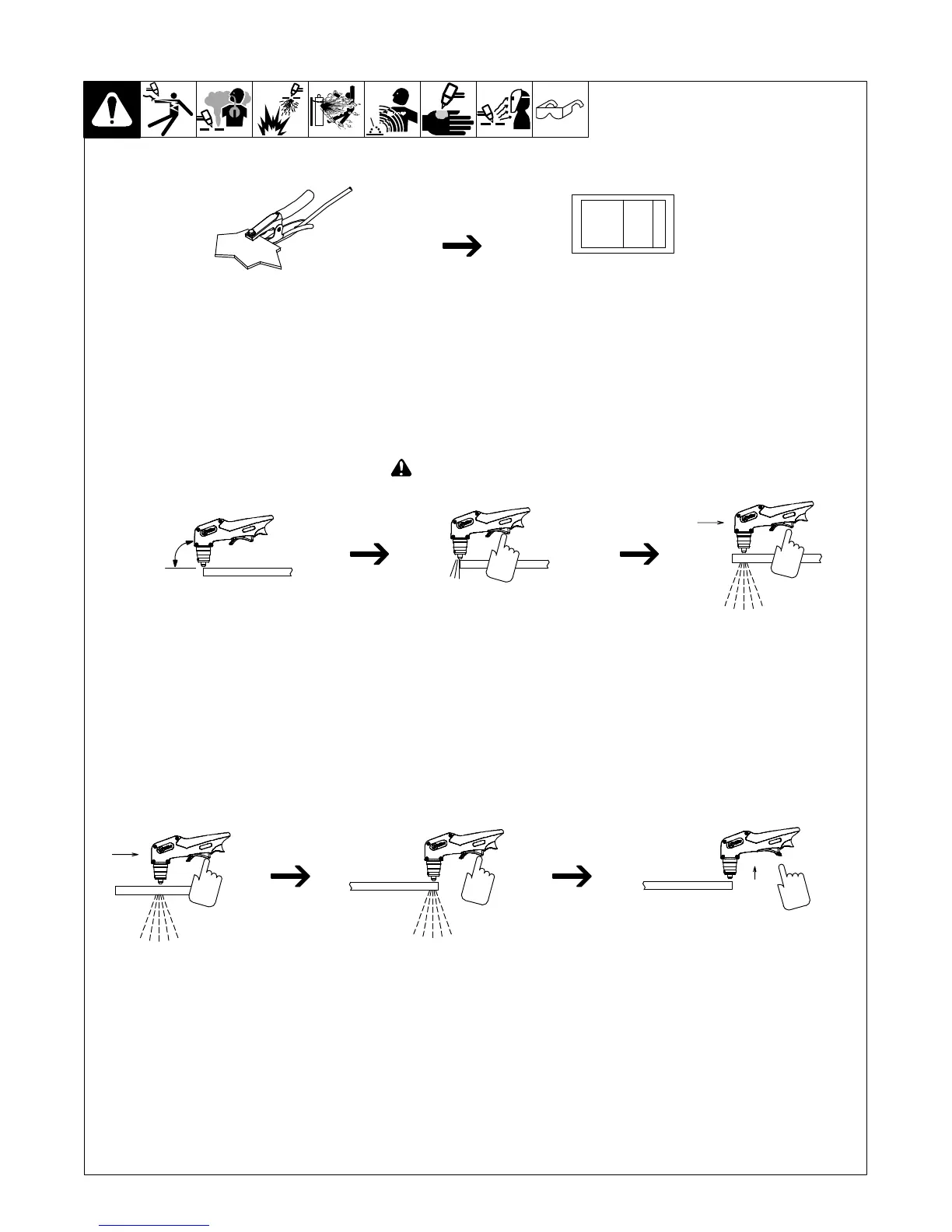

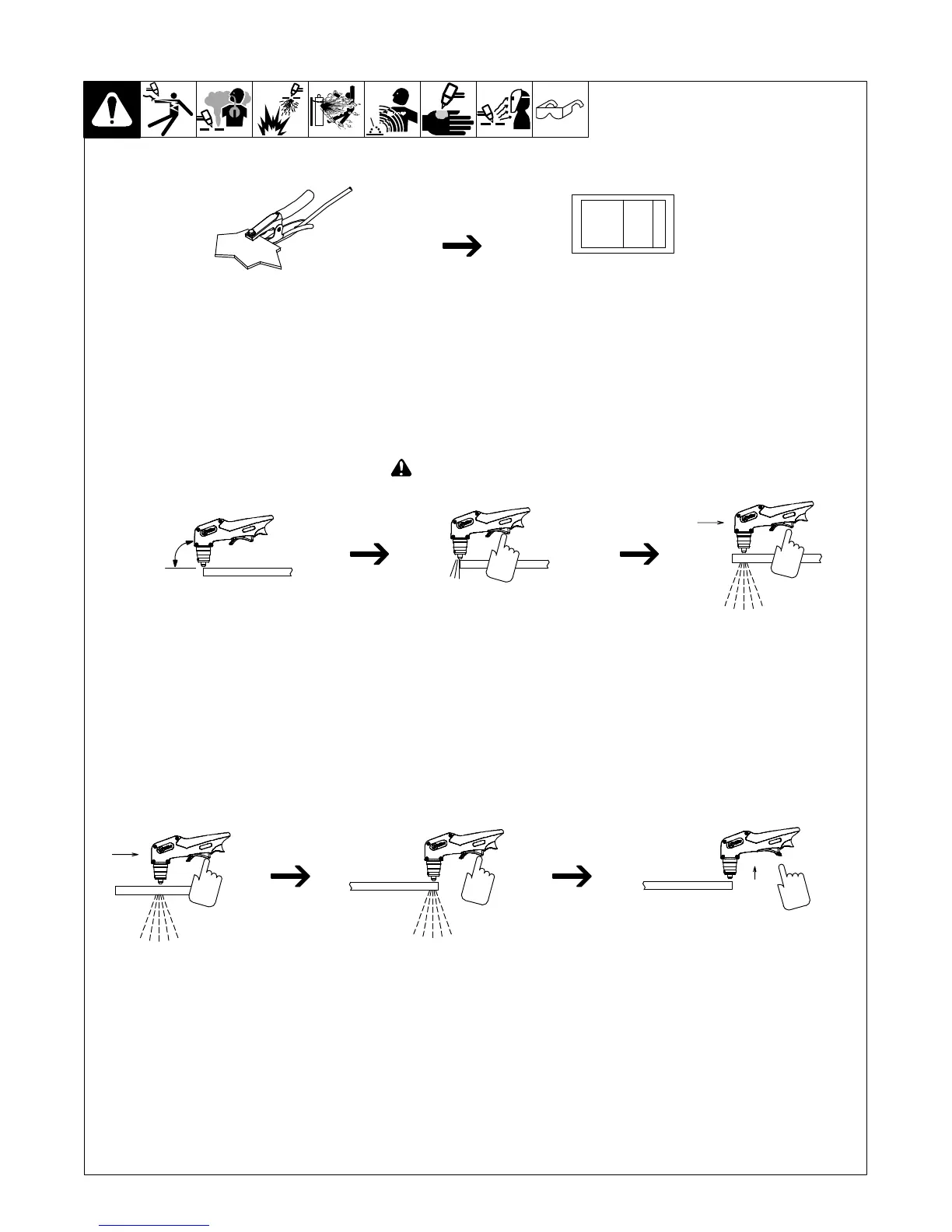

6-5. Sequence Of Cutting Operation

! The pilot arc starts immediately

when trigger is pressed.

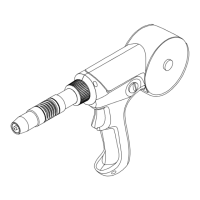

Connect work clamp to a clean, paint-free

location on workpiece, as close to cutting

area as possible.

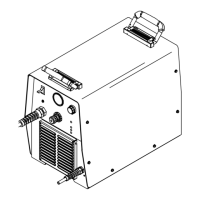

. Unit automatically regulates pressure to 75 psi

(517 kPa) for cutting.

CUT GOUGE

. Connect work clamp to portion of workpiece

that does not fall away after being cut.

. For more information, go to MillerWelds.com.

For standard (shielded) cutting, place drag shield

on edge of metal. For extended (non-shielded)

cutting, use 1/8 in. (3.2 mm) standoff distance

(dragging tip will reduce tip life).

90°

out bottom of cut.

After cutting arc starts, slowly

start moving torch across metal.

Adjust torch speed so

sparks go thru metal and

Pause briefly at end of

cut before releasing trigger.

Raise trigger lock and press

trigger. Pilot arc starts.

Postflow continues for approx. 20 seconds

after releasing trigger; cutting arc can be

instantly restarted during postflow by raising

trigger lock and pressing trigger.

Loading...

Loading...