OM-1216 Page 12

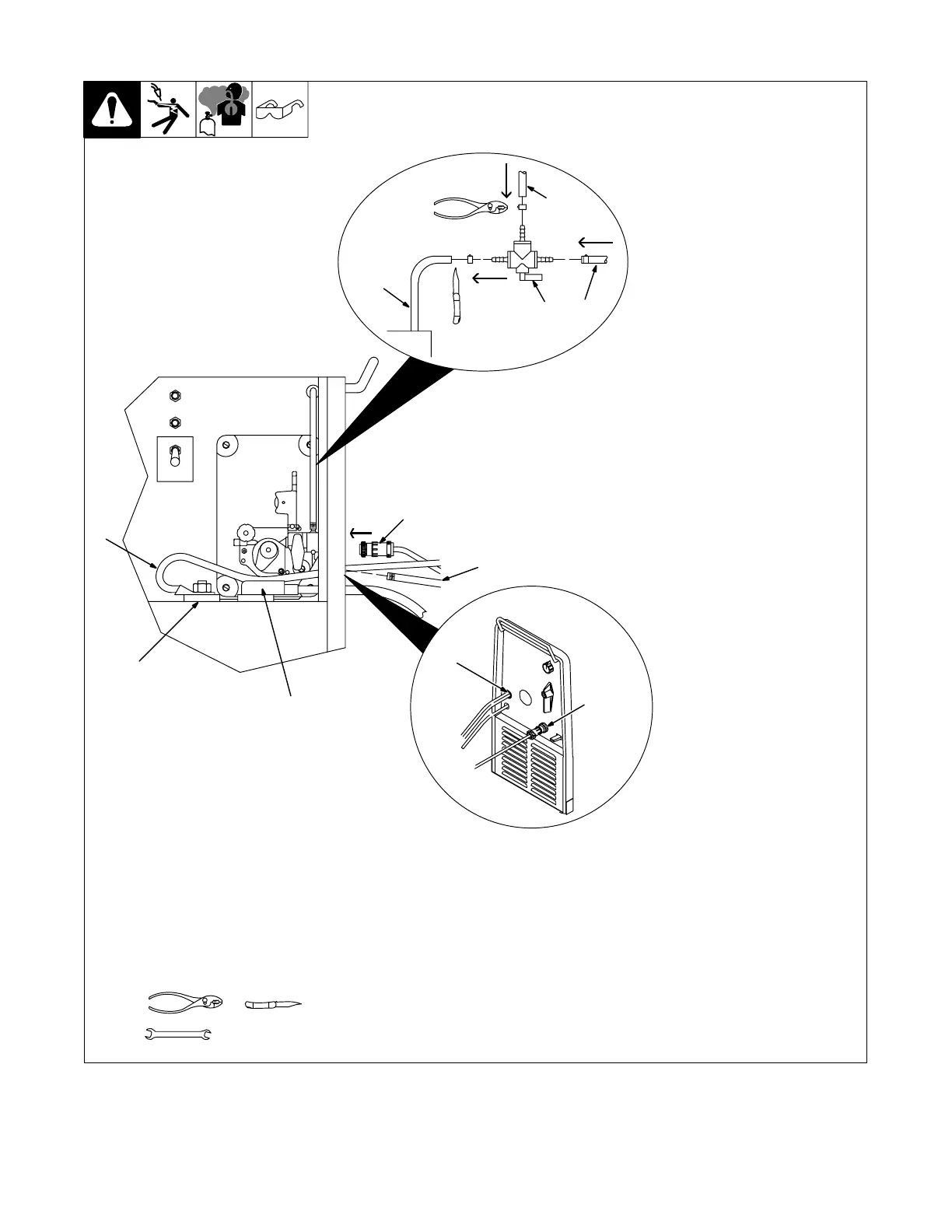

2-6. Connecting Spoolgun To Millermatic 185

Ref. 801 890-A

Tools Needed:

Y Turn Off unit.

Disconnect and remove MIG

(GMAW) welding gun, if applicable.

1 Front Panel Opening

2 Spoolgun Weld Cable

Route weld cable through front pan-

el opening.

3 Positive (+) Output Terminal

Connect spoolgun weld cable to

positive (+) output terminal.

4 Work Clamp Lead

Work clamp lead should be

connected to negative (–) output

terminal.

5 Existing Gas Hose

6 Spoolgun Gas Hose

7 Gas Diverter Valve

To install diverter valve, cut existing

gas hose above barbed fitting at

wire drive housing.

Install supplied hose clamp onto

end of hose at wire drive housing,

and insert either of the two output

barbed ends of diverter valve into

hose. Secure with hose clamp.

Install another supplied hose clamp

onto end of hose from gas supply,

and insert input barbed end of

diverter valve into hose. Secure

with hose clamp.

Slide hose clamp down gas hose

from gun, and cut barbed fitting off

hose. Route gas hose through front

panel opening, and insert

remaining output barbed end of

diverter valve into hose. Secure

with hose clamp.

8 Trigger Control Plug

Insert plug into receptacle, and

tighten threaded collar.

Close welding power source door.

3/4 in

2

3

4

8

1

8

5

7

6

5

6

Loading...

Loading...