Troubleshooting

During troubleshooting, follow the instructions in this manual. A correct installation

is crucial to proper operation.

Before repair or service of the GMP Mixer, personnel must study and understand

the user guide.

Before performing maintenance on the GMP Mixer, make sure that the vessel is:

cooled down to below 25 °C (77 °F)•

emptied of liquid and hazardous gas•

free from traces of harmful products•

It is the customer’s responsibility to check the safety of the GMP Mixer used in a

new application according to:

External load•

Reaction forces and torque•

Corrosion, erosion, and fatigue•

Decomposing of unstable liquids•

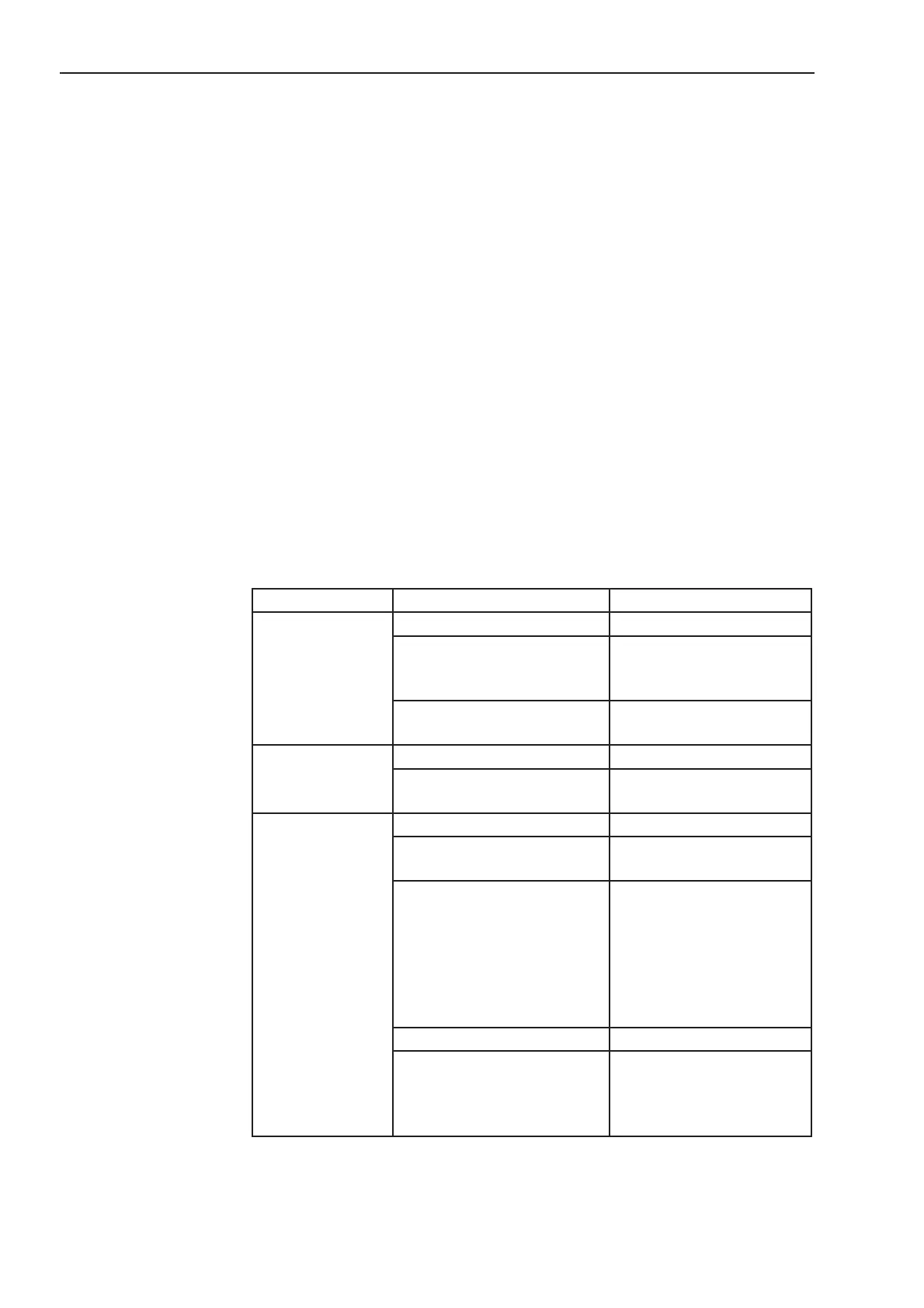

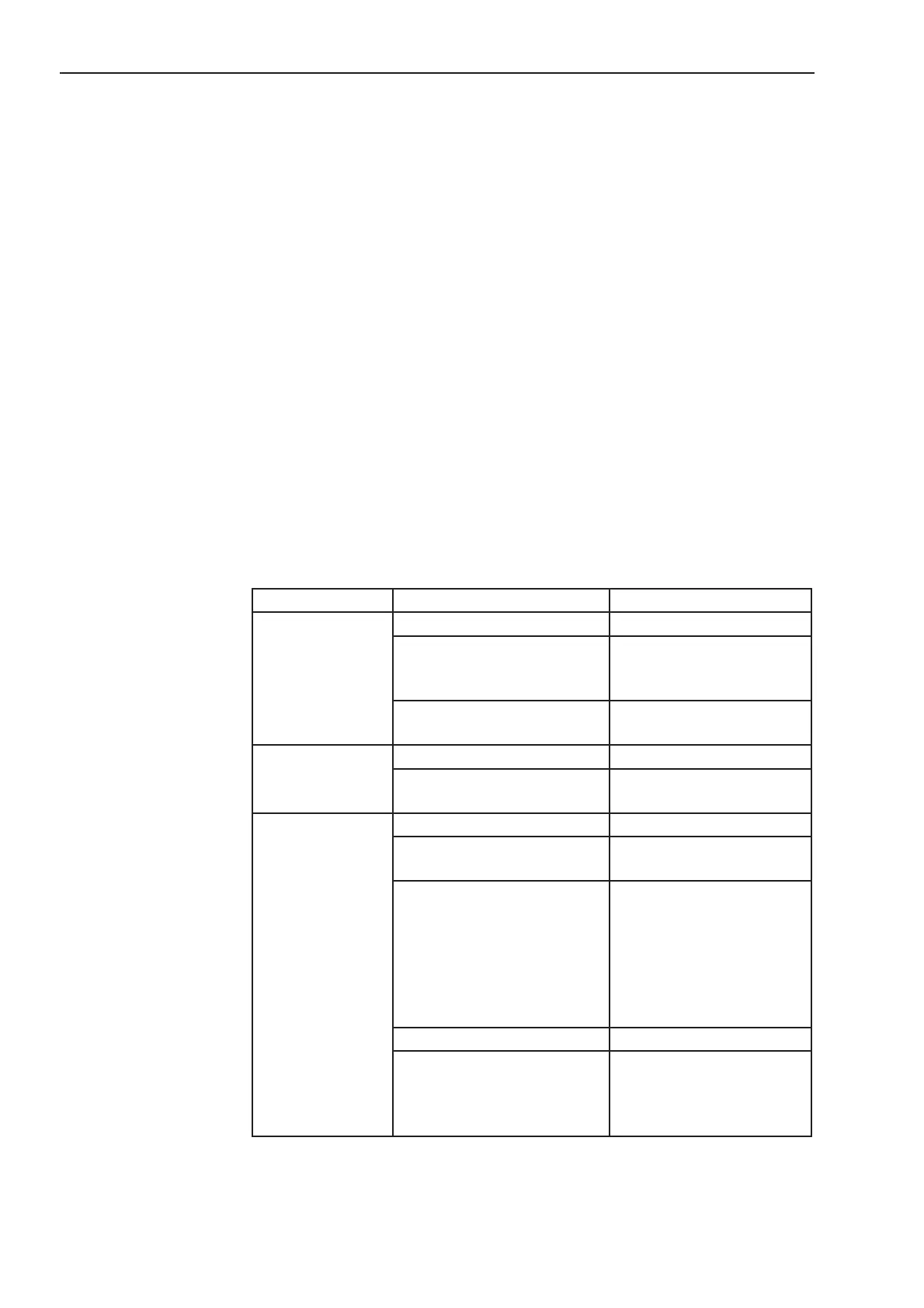

Problem Possible Causes Solutions

Motor/mixing

head does not

rotate

No power Inspect power supply

Overload protection tripped Check the setting amp

value and the ambient tem-

perature

Heavy load of particles stuck

to the magnets

Clean the unit

High amp value Ambient temperatre too high Chill the environment

Motor mechanically over-

loaded

Check all transmissions

Mixing head

scratches against

tank plate

Male bearing worn out Replace male bearing

Female bearing holder is

damaged

Repair mixing head

Loose male bearing Remove male bearing.

Inspect male bearing and

tank plate for damage. If it

is undamaged, reinstall the

bearing and check rotation

direction of the mixing

head.

Particles stuck to the magnets Remove particles.

Deformation after welding Review instructions for

welding the tank plate and

verify tolerances using ap-

propriate gauges.

36 www.millipore.com

Loading...

Loading...