PL-551 XPS 10/15 F Series Transducer Page 5

About the…

About Milltronics’ Transducers

The Echomax XPS F series of transducers operates in association with

Milltronics ultrasonic level monitoring products.

The transducer operates by converting electrical

pulses that are provided by the transceiver into

ultrasonic pulses. When transmitted, these

ultrasonic pulses reflect from the material surface

and echo back to the transducer. The echo is

converted back to an electrical signal, and is

interpreted by the Milltronics tranceiver using

our proven Sonic Intelligence™ algorithms.

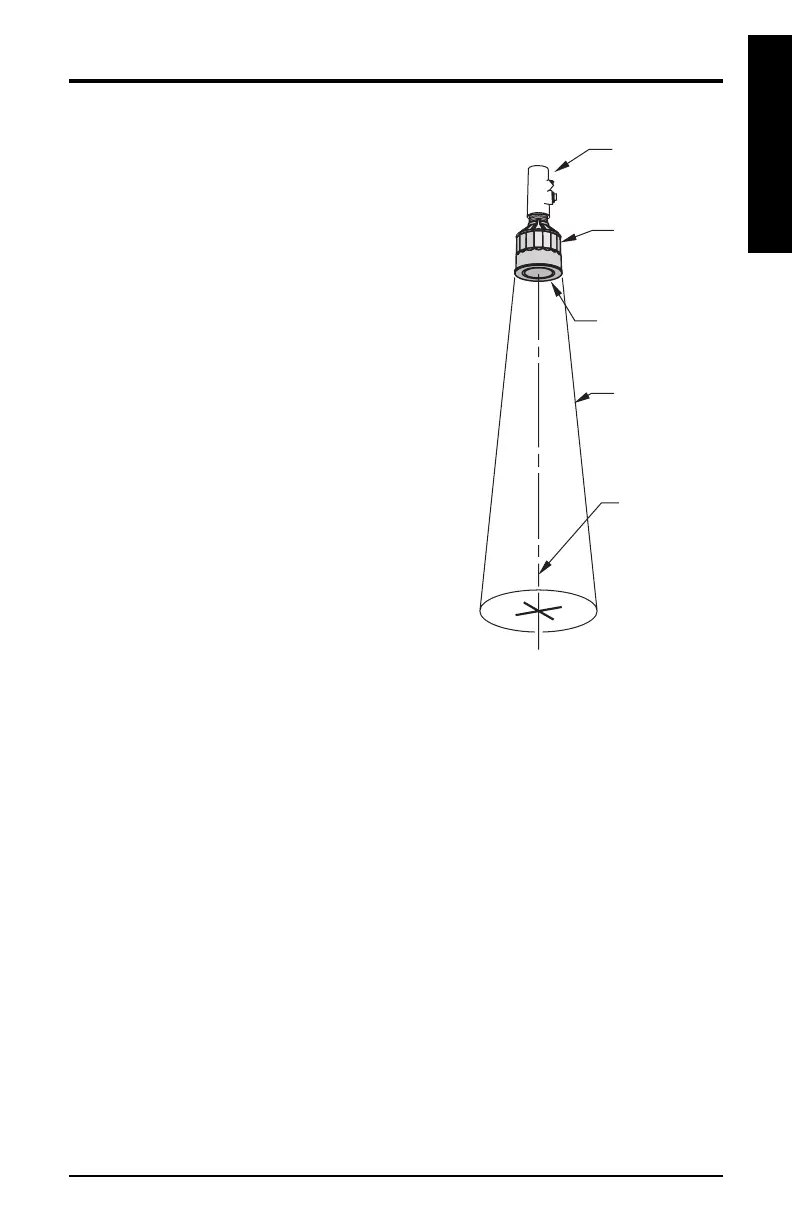

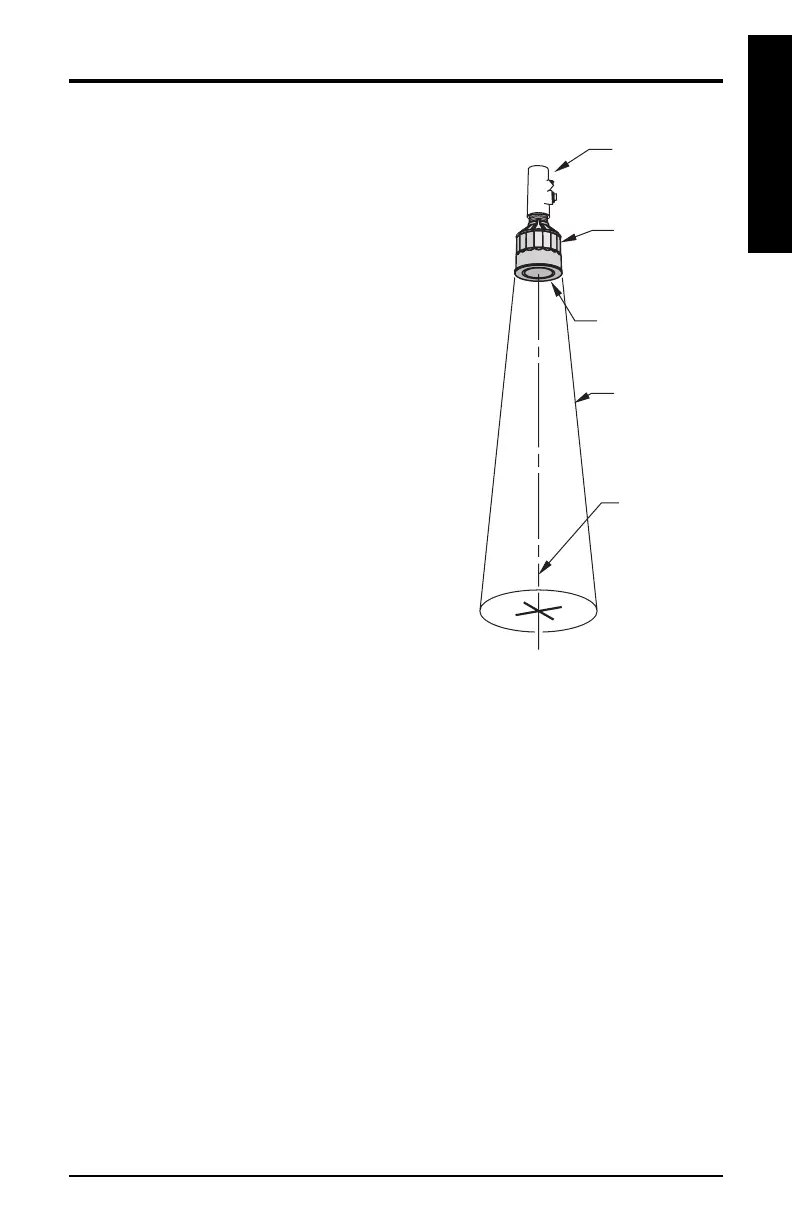

The effective acoustical energy is emitted from

the transducer face and radiated outward,

decreasing in amplitude at a rate inversely

proportional to the square of the distance.

Maximum power is radiated axially

(perpendicular) from the transducer face in a

line referred to as the axis of transmission.

Where power is reduced by half (– 3 dB), a

conical boundary defining the sound beam,

centered about the axis of transmission, is

established. The diametric measurement of

the cone in degrees defines the beam

angle. Impedance matching techniques are

used to optimize the transfer of power from the transducer into air and vice

versa.

The XPS F series transducers incorporate an integral temperature sensor

that reports the air temperature at the transducer to the transceiver. The

connection is transparent, in that both the ultrasonic and temperature

components of the transducer use the same leads.

Hazardous Area Applications

The Echomax XPS F series of transducers can be used in hazardous areas.

For the XPS 10 F series transducer, a hazardous seal must be used to suit

hazardous area classification. This seal is

not

supplied by Milltronics.

The XPS 15 F comes equipped with a stainless steel coupling suitable for

use in hazardous locations.

transducer

transducer face

-3db

boundary

axis of

transmission,

perpendicular

to transducer

face

hazardous seal

(XPS 10 F

series only)

Loading...

Loading...