21

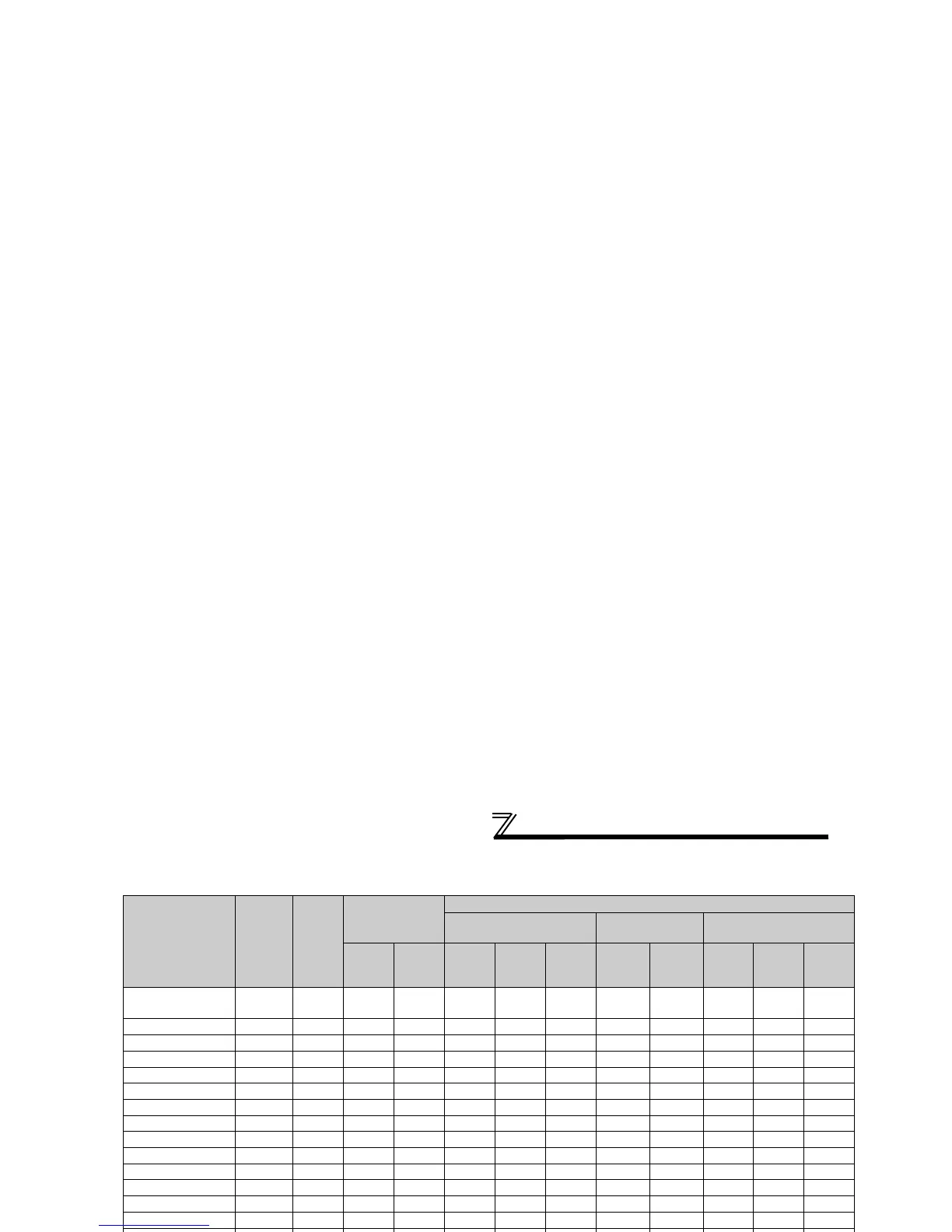

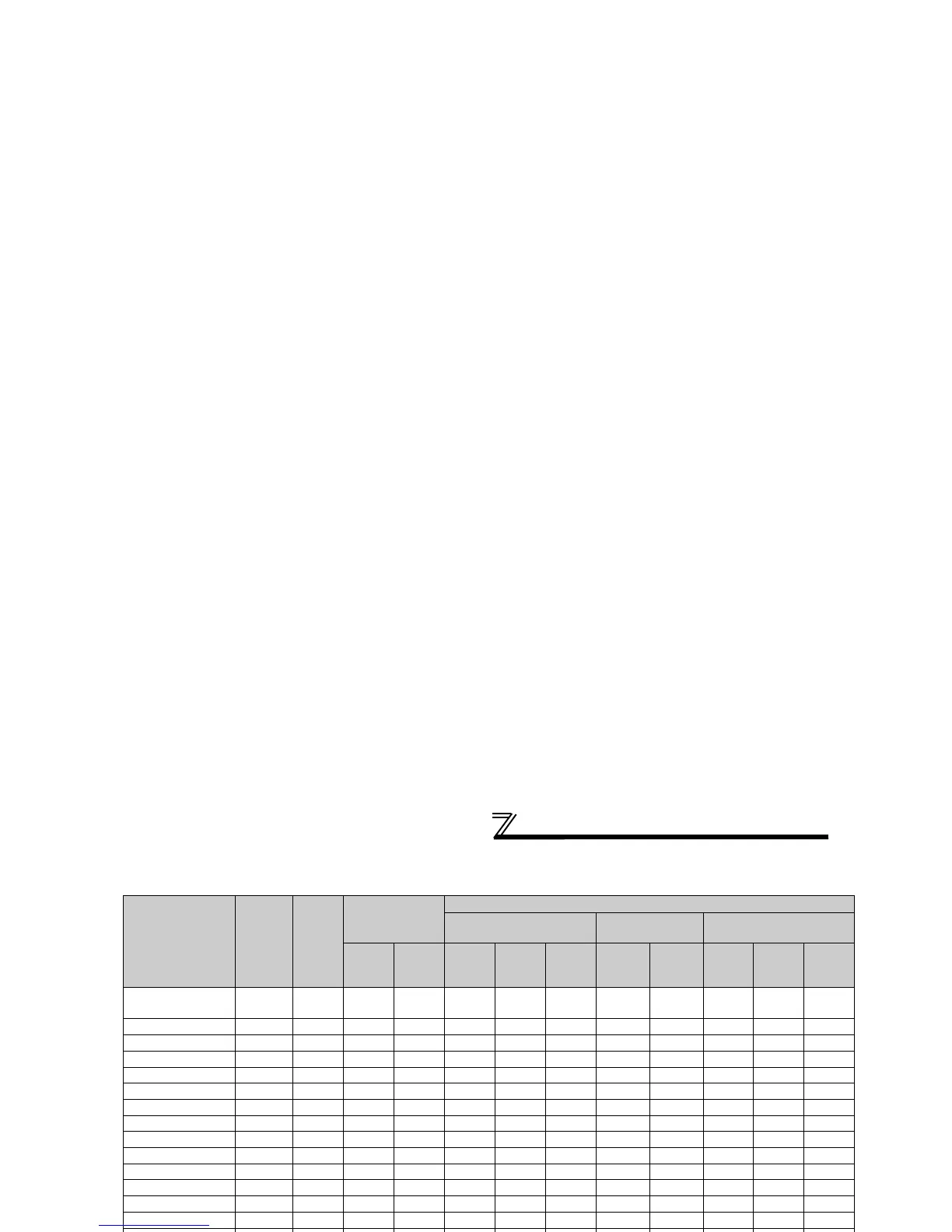

Main circuit terminal specifications

2

WIRING

400V class (when input power supply is 440V)

The line voltage drop can be calculated by the following formula:

line voltage drop [V]=

Use a larger diameter cable when the wiring distance is long or when it is desired to decrease the voltage drop

(torque reduction) in the low speed range.

Applicable

Inverter Type

Terminal

Screw

Size

*4

Tightening

Torque

N·m

Crimping

(Compression)

Terminal

Cable Sizes

HIV, etc. (mm

2

) *1

AWG/MCM *2

PVC, etc. (mm

2

) *3

R/L1, S/L2,

T/L3

U, V, W

R/L1, S/L2,

T/L3

U, V, W

Earth

(Ground)

cable

R/L1, S/L2,

T/L3

U, V, W

R/L1, S/L2,

T/L3

U, V, W

Earth

(Ground)

cable

FR-F740-0.75K to

3.7K

M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-F740-5.5K M4 1.5 2-4 2-4 2 2 3.5 12 14 2.5 2.5 4

FR-F740-7.5K M4 1.5 5.5-4 5.5-4 3.5 3.5 3.5 12 12 4 4 4

FR-F740-11K M4 1.5 5.5-4 5.5-4 5.5 5.5 8 10 10 6 6 10

FR-F740-15K M5 2.5 8-5 8-5 8 8 8 8 8 10 10 10

FR-F740-18.5K M5 2.5 14-5 8-5 14 8 14 6 8 16 10 16

FR-F740-22K M6 4.4 14-6 14-6 14 14 14 6 6 16 16 16

FR-F740-30K M6 4.4 22-6 22-6 22 22 14 4 4 25 25 16

FR-F740-37K M6 4.4 22-6 22-6 22 22 14 4 4 25 25 16

FR-F740-45K M8 7.8 38-8 38-8 38 38 22 1 2 50 50 25

FR-F740-55K M8 7.8 60-8 60-8 60 60 22 1/0 1/0 50 50 25

FR-F740-75K M8 7.8 60-8 60-8 60 60 38 1/0 1/0 50 50 25

FR-F740-90K M10 14.7 60-10 60-10 60 60 38 3/0 3/0 50 50 25

FR-F740-110K M10 14.7 80-10 80-10 80 80 38 3/0 3/0 70 70 35

FR-F740-132K M10 14.7 100-10 150-10 100 125 38 4/0 4/0 95 95 50

FR-F740-160K M10 14.7 150-10 150-10 125 125 38 250 250 120 120 70

FR-F740-185K M12-M10 24.5 150-12 150-12 150 150 38 300 300 150 150 95

FR-F740-220K M12-M10 24.5 100-12 100-12 2×100 2×100 38 2×4/0 2×4/0 2×95 2×95 95

FR-F740-250K M12-M10 24.5 100-12 100-12 2×100 2×100 38 2×4/0 2×4/0 2×95 2×95 95

FR-F740-280K M12-M10 24.5 150-12 150-12 2×125 2×125 38 2×250 2×250 2×120 2×120 120

FR-F740-315K M12-M10 24.5 150-12 150-12 2×150 2×150 38 2×300 2×300 2×150 2×150 150

FR-F740-355K M12-M10 24.5 200-12 200-12 2×200 2×200 60 2×350 2×350 2×185 2×185 2×95

FR-F740-400K M12-M10 24.5 C2-200 C2-200 2×200 2×200 60 2×400 2×400 2×185 2×185 2×95

FR-F740-450K M12-M10 24.5 C2-250 C2-250 2×250 2×250 60 2×500 2×500 2×240 2×240 2×120

FR-F740-500K M12-M10 24.5 C2-250 C2-250 2×250 2×250 100 2×500 2×500 2×240 2×240 2×120

FR-F740-560K M12-M10 24.5 C2-200 C2-200 3×200 3×200 100 3×350 3×350 3×185 3×185 2×150

*1 For the FR-F740-55K or less, the recommended cable size is that of the cable (e.g. HIV cable (600V class 2 vinyl-insulated cable)) with continuous

maximum permissible temperature of 75°C. Assumes that the ambient temperature is 50°C or less and the wiring distance is 20m or less.

For the FR-F740-75K or more, the recommended cable size is that of the cable (e.g. LMFC (heat resistant flexible cross-linked polyethylene insulated

cable)) with continuous maximum permissible temperature of 90°C. Assumes that the ambient temperature is 50°C or less and wiring is performed in an

enclosure.

*2 For the FR-F740-45K or less, the recommended cable size is that of the cable (THHW cable) with continuous maximum permissible temperature of 75°C.

Assumes that the ambient temperature is 40°C or less and the wiring distance is 20m or less.

For the FR-F740-55K or more, the recommended cable size is that of the cable (THHN cable) with continuous maximum permissible temperature of 90°C.

Assumes that the ambient temperature is 40°C or less and wiring is performed in an enclosure.

(Selection example for use mainly in the United States.)

*3 For the FR-F740-45K or less, the recommended cable size is that of the cable (PVC cable) with continuous maximum permissible temperature of 70°C.

Assumes that the ambient temperature is 40°C or less and the wiring distance is 20m or less.

For the FR-F740-55K or more, the recommended cable size is that of the cable (XLPE cable) with continuous maximum permissible temperature of 90°C.

Assumes that the ambient temperature is 40°C or less and wiring is performed in an enclosure.

(Selection example for use mainly in the Europe.)

*4 The terminal screw size indicates the terminal size for R/L1, S/L2, T/L3, U, V, W, and a screw for earthing (grounding).

For the 185K or more, screw sizes are different. (<R/L1, S/L2, T/L3, U, V, W> - <a screw for earthing (grounding)>)

CAUTION

· Tighten the terminal screw to the specified torque.

A screw that has been tighten too loosely can cause a short circuit or malfunction.

A screw that has been tighten too tightly can cause a short circuit or malfunction due to the unit breakage.

· Use crimping terminals with insulation sleeve to wire the power supply and motor.

3 × wire resistance[mΩ/m] × wiring distance[m] × current[A]

1000

Loading...

Loading...