6 - 23

MELSEC-A

6 SEQUENCE PROGRAM USED FOR POSITIONING CONTROL

6.5.3 Start program

This program is used to start the control with start commands.

The control can be started with the following two methods.

(1) Starting by inputting positioning start signal [Y10, Y11, Y12]

(2) Starting by inputting external start signal

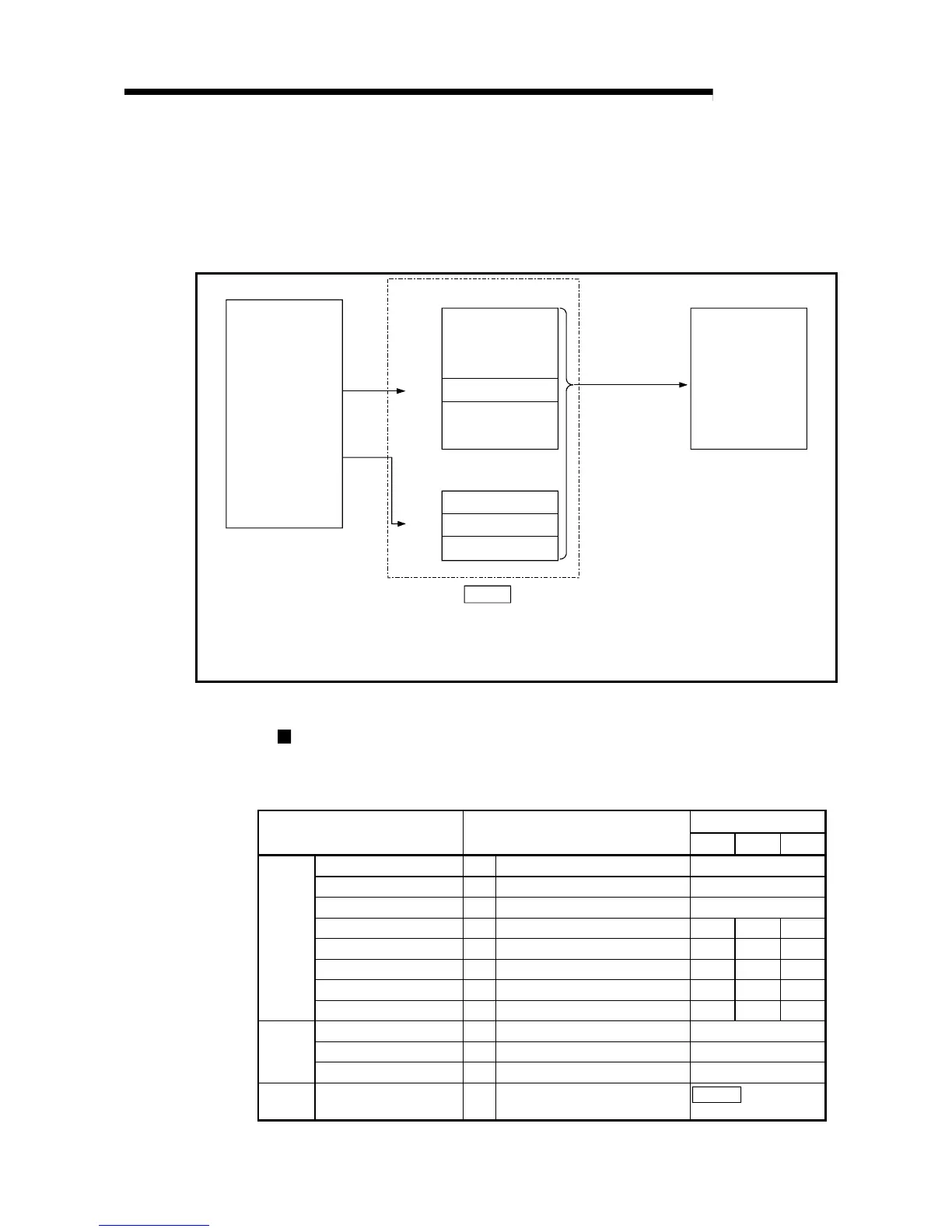

PLC CPU

Buffer memory

1150

Input/output signal

1

1)

ON

2)

Y10

Servo amplifier

Control with

positioning data

No. 1

3)

When starting positioning with the scan

after the completion of positioning,

insert X1 as an interlock so that

positioning is started after Y10 is turned

OFF and X1 is turned OFF.

*

1) Set the "positioning start No." in " Cd.11 Positioning start No." according to the control to

be started.

(In the above example, set positioning data No. "1".)

2) Input the positioning start signal [Y10, Y11, Y12] or the external start signal.

3) The positioning data No. "1" will start.

Fig. 6.2 Procedures for starting control

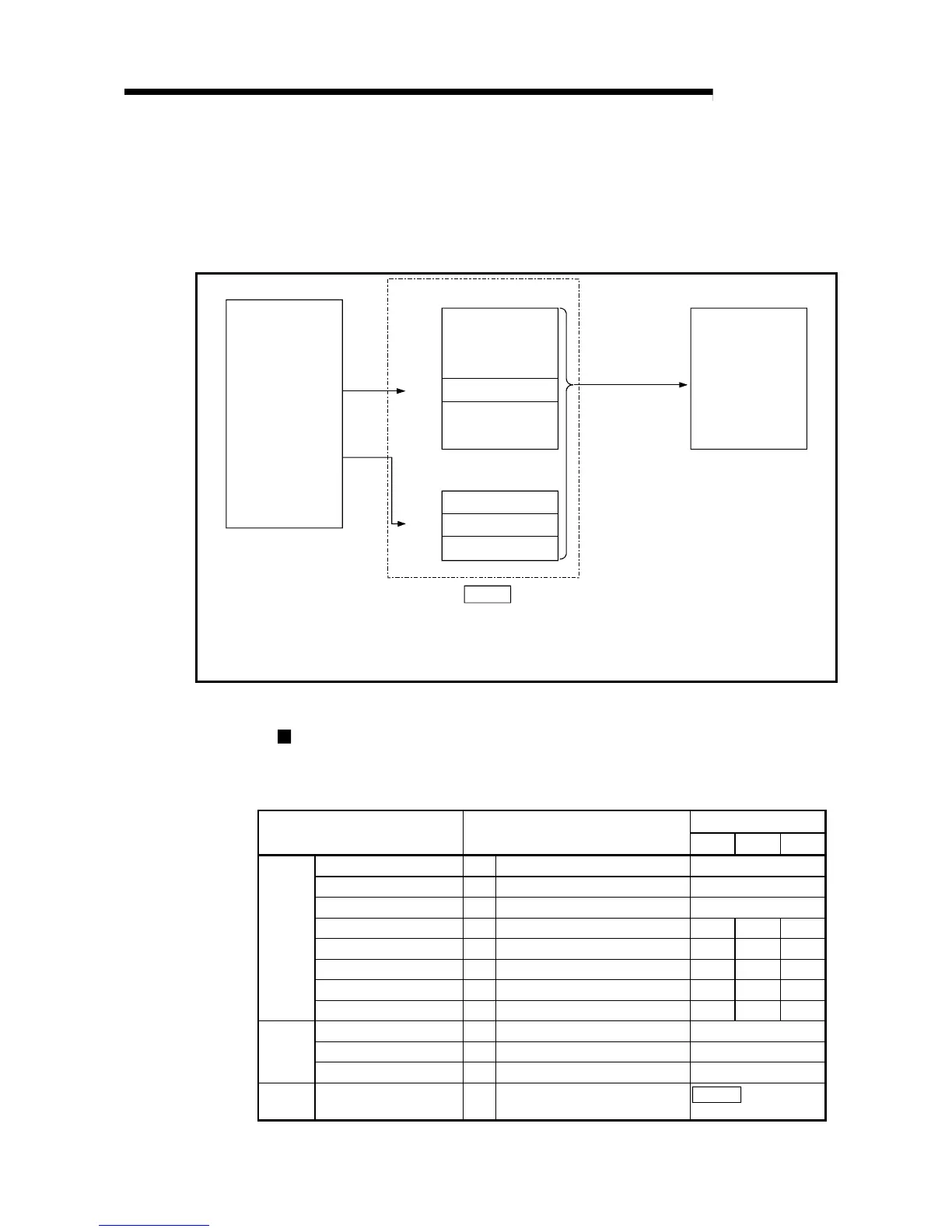

Starting conditions

When starting, the following conditions must be satisfied. The program must be

configured by adding the required conditions into the sequence program so that

the operation does not start until the conditions are satisfied.

Device

Signal name Signal state

Axis 1 Axis 2 Axis 3

All axes servo ON signal ON Servo operation possible Y15

PLC READY signal ON PLC CPU preparation completed Y1D

AD75 READY signal OFF AD75 preparation completed X0

Axis stop signal OFF Axis stop signal is OFF Y13 Y14 Y1C

Start complete signal OFF Start complete signal is OFF X1 X2 X3

BUSY signal OFF BUSY signal is OFF X4 X5 X6

Error detection signal OFF There is no error XA XB XC

Interface

signal

M code ON signal OFF M code ON signal is OFF XD XE XF

Stop signal OFF Stop signal is OFF –

Upper limit (FLS) ON Within limit range –

External

signal

Lower limit (RLS) ON Within limit range –

Monitor

data

Servo ON ON Servo ON is ON

Md.116

Servo status:

b1

Loading...

Loading...