12 - 29

MELSEC-A

12 CONTROL AUXILIARY FUNCTIONS

(4) Setting the torque limit function

(a) To use the "torque limit function", set the "torque limit value" in the axis

control data or parameters indicated in the following table, and write them to

the AD75.

The data set to the axis control data is validated at the rising edge (OFF to

ON) of the PLC READY signal (Y1D) and at a start of the corresponding

control.

The data set to the parameters are validated at the rising edge (OFF to ON)

of the PLC READY signal (Y1D).

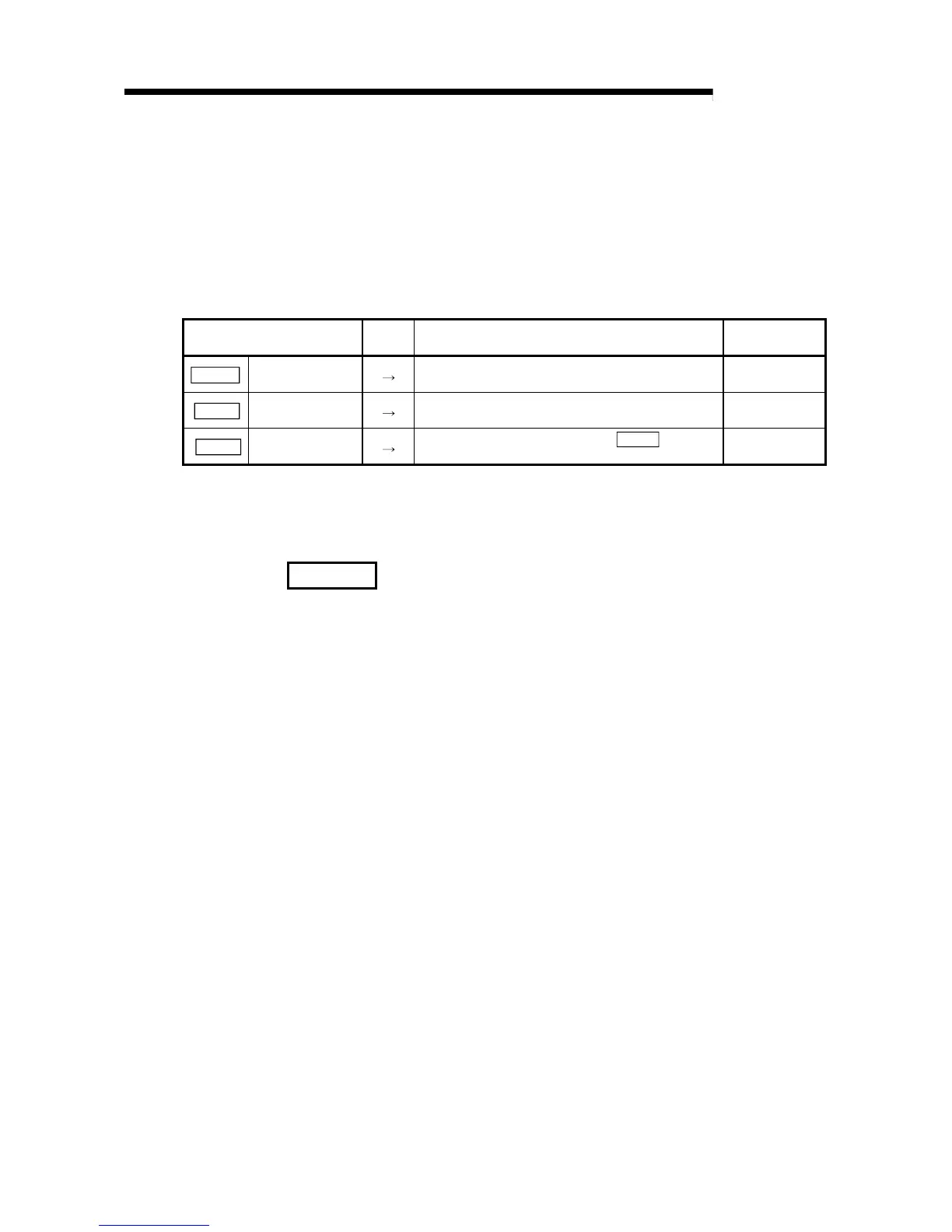

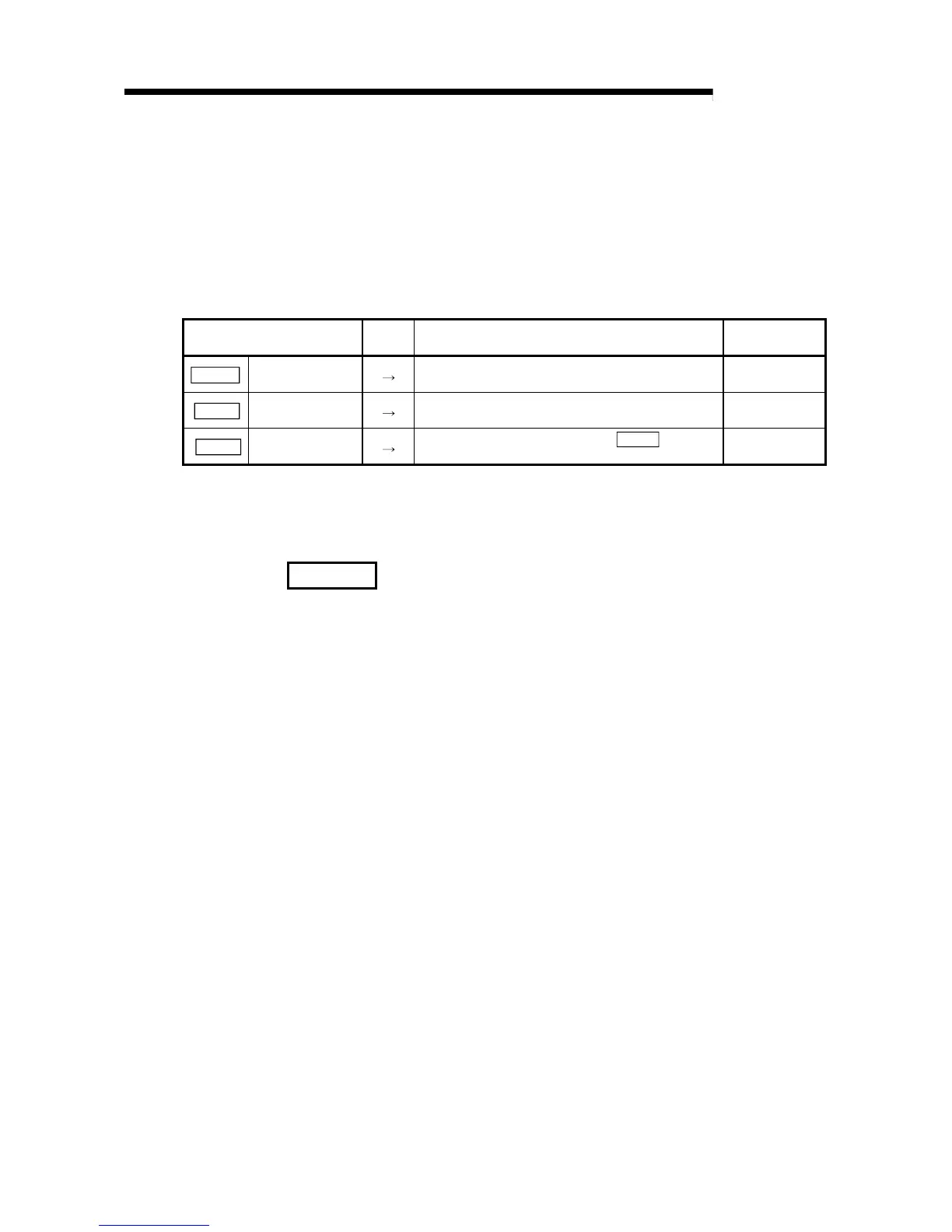

Setting item

Setting

value

Setting details

Factory-set

initial value

Cd.101

Torque output

setting value

Set the torque limit value to be output by the

servomotor in %.

0

Pr.18

Torque limit

setting value

Set the torque limit value as a percentage. 300

Pr.56

Zero point return

torque limit value

Set the torque limit value after the "

Pr.49

Creep

speed" is reached. Set as a percentage.

300

* Refer to section "5.2 List of parameters" and "5.7 List of control data" for setting details.

(b) The "torque limit value" set in the AD75 is transferred to the servo amplifier

at a start of the corresponding control to limit the torque.

REMARK

•

Parameters are set for each axis.

•

It is recommended that the parameters be set whenever possible with the AD75

software package. Execution by sequence program uses many sequence

programs and devices. The execution becomes complicated, and the scan times

will increase.

Loading...

Loading...