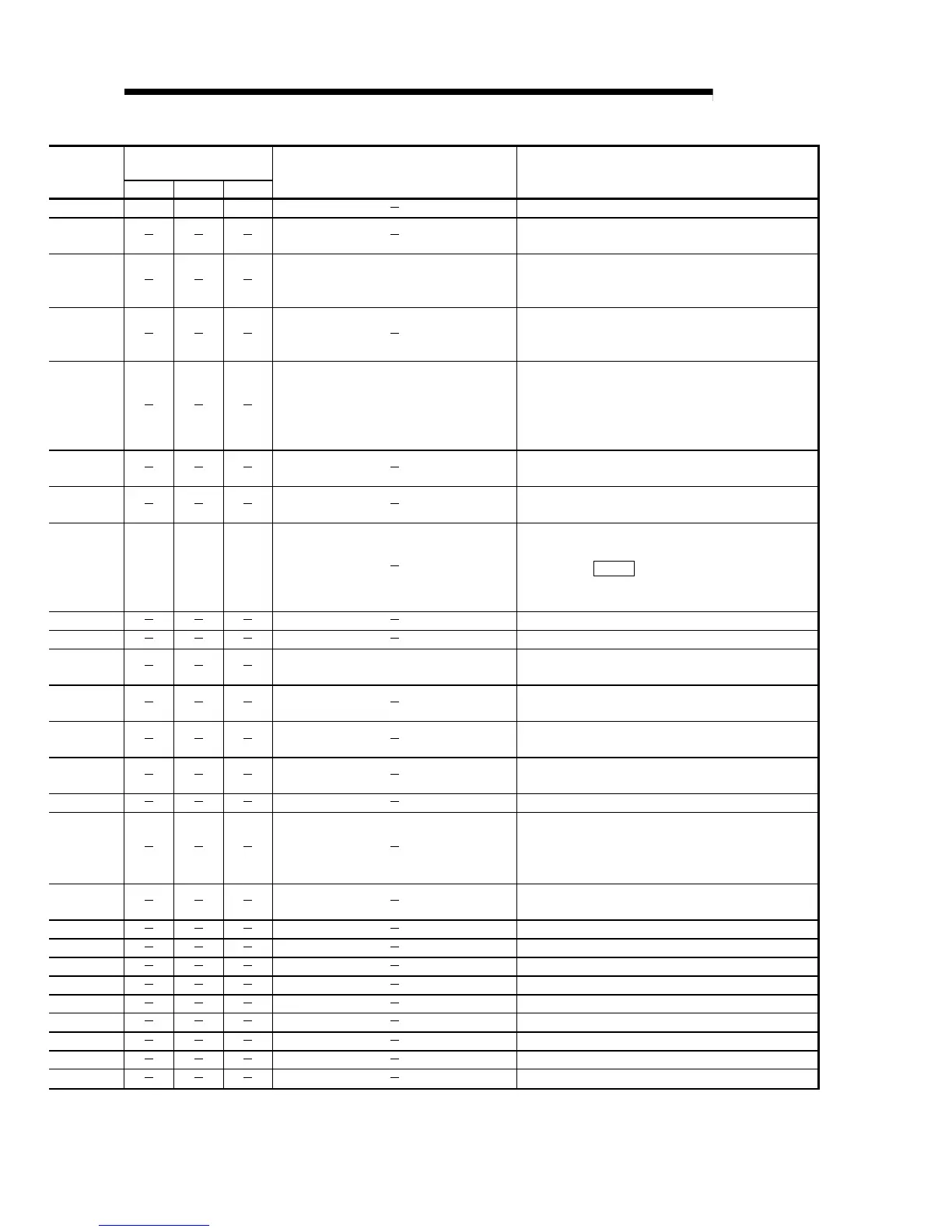

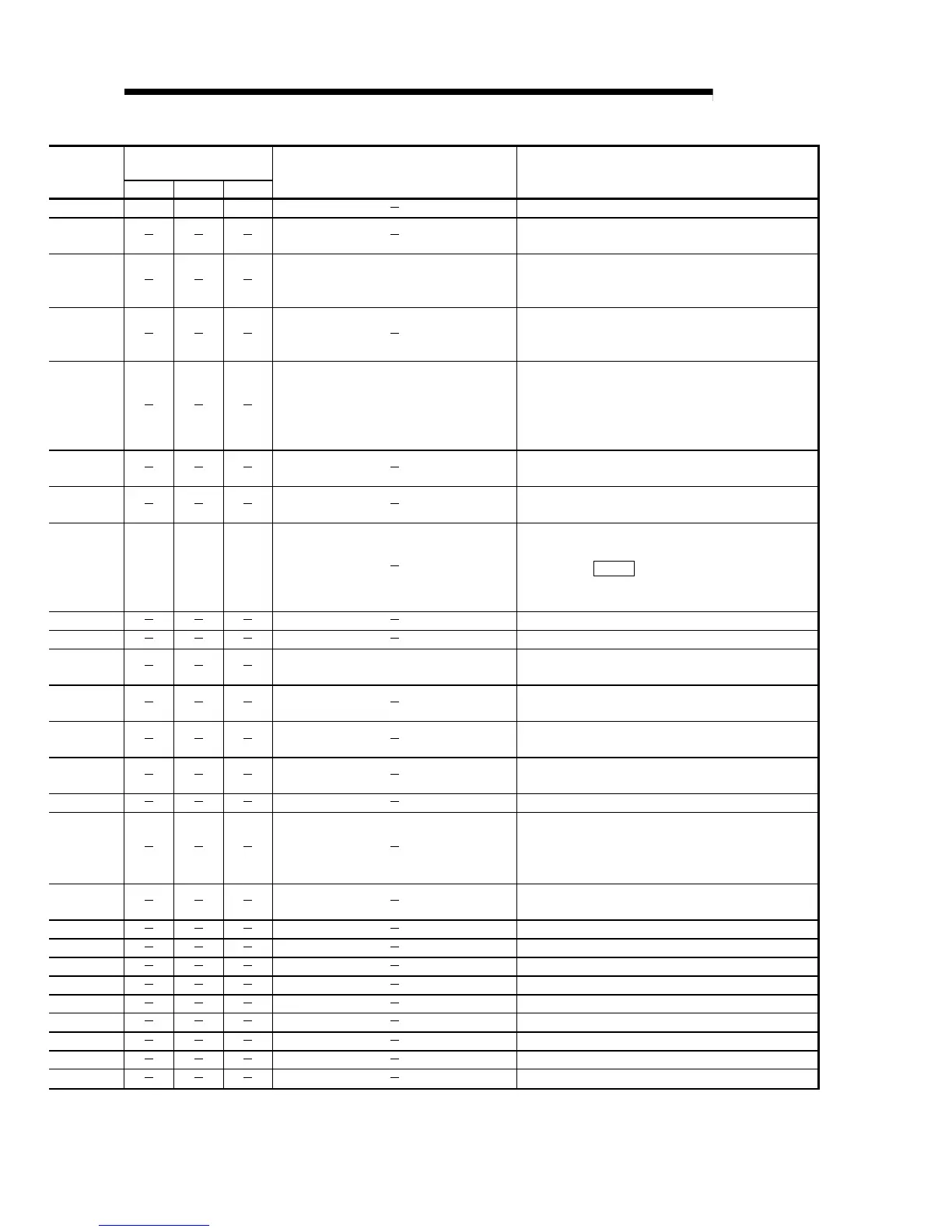

14 - 53

MELSEC-A

14 TROUBLESHOOTING

Relevant buffer memory

addresses

Axis 1 Axis 2 Axis 3

Checking method Remedy

102 252 402 Set correctly.

Connect correctly.

Call the status display and check the

regenerative load ratio.

1. Reduce the frequency of positioning.

2. Use the regenerative brake option of larger capacity.

3. Reduce the load.

Review the power supply.

1) The regenerative brake option has

overheated abnormally.

2) Error occurs even after removal of the built-

in regenerative brake resistor or

regenerative brake option.

Change the servo amplifier.

Change the servo amplifier or regenerative brake option.

Increase acceleration/deceleration time constant.

112 262 412

1. Re-set servo gain to proper value.

2. If servo gain cannot be set to proper value:

1) Reduce " Pr.112 Load inertia ratio" (load inertia

moment ratio); or

2) Reexamine acceleration/deceleration time constant.

Change the servomotor.

Correct the wiring.

Error code 2032 occurs if power is switched

ON after U, V and W are disconnected.

Change the servo amplifier.

Correct the wiring.

Take noise suppression measures.

1. Change lead.

2. Connect correctly.

Change the servo amplifier.

1. For wire breakage of built-in regenerative brake

resistor, change servo amplifier.

2. For wire breakage of regenerative brake option, change

regenerative brake option.

Add regenerative brake option or increase capacity.

Review the power supply.

Connect correctly.

Change the cable.

Take noise suppression measures.

Connect correctly.

Set correctly.

Review the operation program.

Take noise suppression measures.

Change the AD75.

Loading...

Loading...