Appendix - 43

MELSEC-A

APPENDICES

POSITIONING START

This refers the act of designating a target data

No. and starting the positioning.

The operation after the positioning is complete

for that data No. is determined by the data

No.'s positioning pattern.

PTP Control (Point To Point Control)

This is a type of positioning control. With this

control method, the points to be passed are

designated at random locations on the path.

Movement only to a given target positioning is

requested. Path control is not required during

movement from a given point to the next value.

PU (Programming Unit)

This is the abbreviation for "programming unit".

PULSE

The turning ON and OFF of the current

(voltage) for short periods. A pulse train is a

series of pulses.

REAL-TIME AUTO TUNING (Real-time

Automatic Tuning)

Refer to "AUTO TUNING".

REFERENCE AXIS SPEED

This is the speed of the reference axis during

interpolation operations.

axis speed

(interpolation axis)

X axis speed

(reference axis)

Reference axis speed

REGENERATIVE BRAKE OPTION

This function is an option. It is used when

carrying out highly repetitive

acceleration/deceleration.

Refer to "EXTERNAL REGENERATIVE

RESISTOR".

RLS SIGNAL (Reverse Limit Signal)

This is the input signal that notifies the user

that the limit switch (b contact configuration,

normally continuity) installed at the lower limit

of the positioning control enabled range was

activated.

The positioning operation stops when the RLS

signal turns OFF (non-continuity).

ROTARY TABLE

A round table on which the workpiece is

placed. Positioning control is carried out while

rotating the workpiece in a 360

°

range.

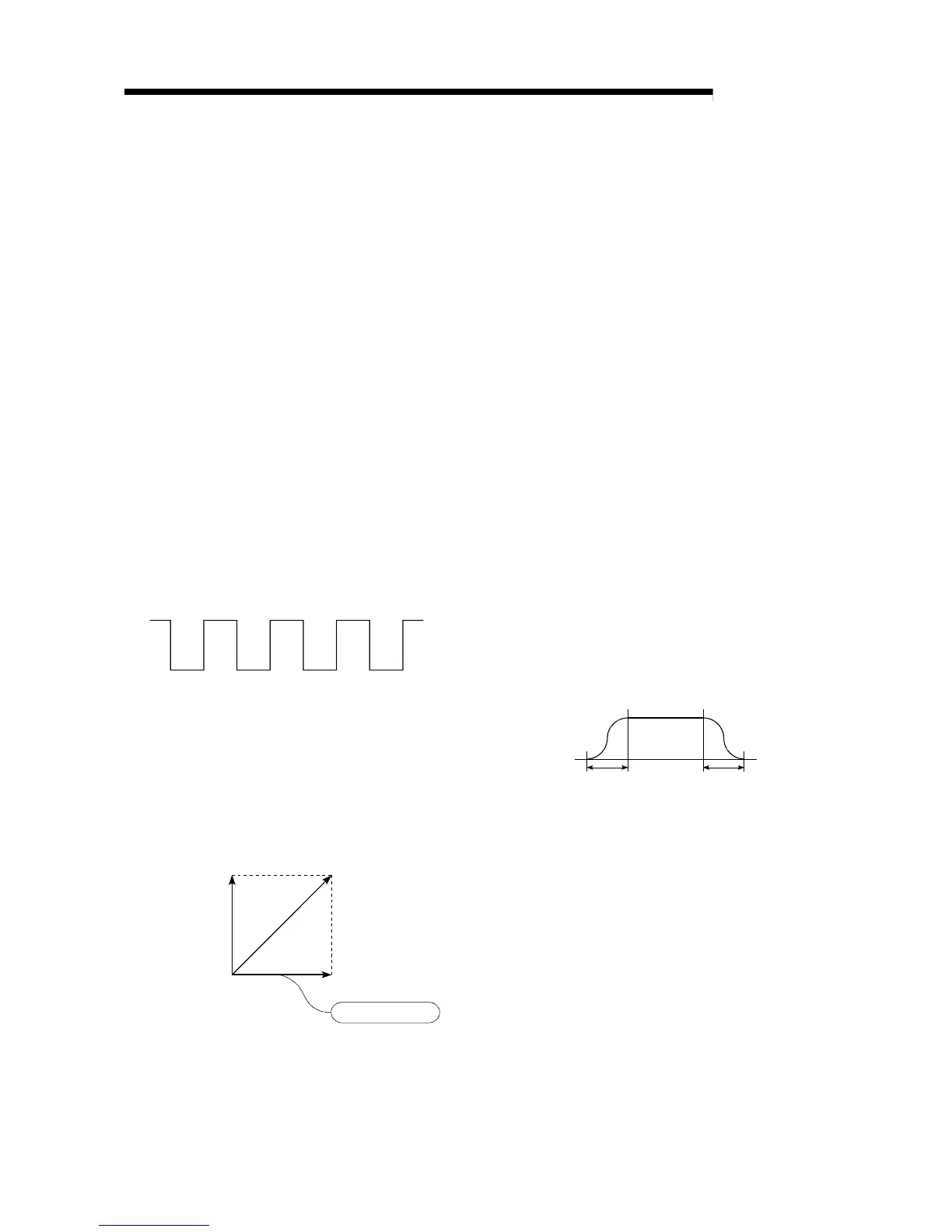

S-PATTERN

ACCELERATION/DECELERATION

In this pattern, the acceleration and

deceleration follow a sine curve, and the

movement is smooth. The S-pattern proportion

can be set from 1 to 100%.

Loading...

Loading...