Do you have a question about the Mitsubishi Ecodan and is the answer not in the manual?

Details specifications like weight, dimensions, electrical data, and performance metrics for cylinder units.

Identifies and labels internal components of cylinder units using diagrams.

Provides dimensional and connection layout drawings for the cylinder units.

Lists compatible outdoor unit models for various cylinder unit configurations.

Illustrates internal water pipework and component connections within the cylinder units.

Shows integration into external heating/cooling systems, including zone control.

Guidelines for selecting installation location, transportation, handling, and positioning the unit.

Outlines water quality requirements, system flushing, and addition of inhibitors and antifreeze.

Details procedures for connecting hot and cold water pipework, including expansion vessel sizing.

Refers to outdoor unit manual for refrigerant pipework connection and adapter requirements.

Explains UK Building Regulation requirements for safety device discharge pipework installation.

Provides detailed instructions for connecting power supplies and wiring for single and three-phase systems.

Explains the purpose and default settings of the DIP switches on the FTC4 control board.

Details wiring specifications for signal inputs, thermistors, and outputs on the FTC4 control board.

Guides wiring for 2-zone temperature control systems, including pumps, switches, and thermistors.

Describes options for connecting remote controllers or thermostats for system control.

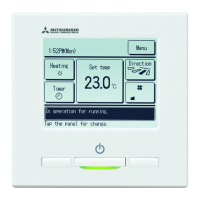

Details the process for removing and remotely installing the main controller unit.

Provides instructions and precautions for using an SD memory card for settings and data storage.

Explains main controller functions, screen icons, and navigation menus.

Provides access to installer/service engineer functions, protected by password.

Outlines initial steps for preparing potable and DHW circuits before commissioning.

A checklist of essential checks to ensure the cylinder unit system is ready for commissioning.

Lists common faults, causes, and recommended solutions for cylinder unit issues.

Details specific error codes displayed on the controller and the corresponding actions to take.

Provides a schedule and guide for performing annual servicing of the cylinder unit and its components.

Refers to the outdoor unit manual for details on refrigerant collection procedures.

Explains how the boiler functions as a backup heat source for the system.

| Type | Air Source Heat Pump |

|---|---|

| Refrigerant | R32 |

| Noise Level | 45 - 60 dB |

| Operating Temperature Range (Cooling) | 46°C |

| Energy Efficiency Ratio (Heating) | A+++ |

| Energy Efficiency Ratio (Cooling) | A++ |

| COP | Up to 4.9 (depending on model and conditions) |

Loading...

Loading...