23.

INSPECTION AND MAIN'TEMNCE

23.3

Replacing

Pam

The inverter consists of a number of electronic component

parts

such

as

semiconductor

devices.

Due

to their

physical

properties,

it

is anticipated that the following component

patts

will deteriorate

with time,

kadw

to troubles or hered performance of the inverter. They should

be

rephced

at regular Intervals for preventive maintenance.

(1)

Cooling fan

A cooling fan is used to cool heat generating parts such as semiconductor devices in the

main circuit. Although the service life

of

the bearing used in the cooling fan is, under normal

operating conditions,

20,000

hours, it will vary in the range of

10,OOO

to

35,000

hours

depending on ambient temperatures.

Therefore, if the system

is

continuously operated, it is necessary to replace the cooling fan

assembly every

two

to three years. Beside this regular replacement, if abnormal noise or

vibration is detecled during inspection, the cooling fan assembly should

be

replaced imme-

diately.

A

large capacity aluminum electrolytic capacitor for smoothing the current is

used

in me direct

current circuit

in

the main circuit.

The

performance of the capacitor

is

degraded due to the

influence of ripple, etc. Although the service life

of

the capacitor varies depending on the am-

bient temperatures and operating conditions, the capacitor should be replaced every five

years assuming that the parameter unit is used within specified environmental limits.

Since the deterioration of a capacitor accelerates over lime, it should be checked at least

once a year. As it approaches the end of service life, it should be checked every six months

or at shorter intenals. The inspection items and defects which require the capacitor to be

replaced are summarized below.

1)

Case conditions: Expansion

of

the case at the side and bottom

2)

Sealing conditions: Excessive curvature or cracks

3)

Safety valve conditions: Excessive expansion

of

the valve or an actuated valve

4)

Others:

(2)

Smoothing

wpncltor

Check for cracks, discoloration, leakage, or other defects. Measure the capacity.

If

measured capacity is less than

85%

of rated, the capacitor should

be

replaced.

(3)

Relays

Relay contacts deteriorate with use. Relays should be replaced according to the total number

of

makebreak operations (service life).

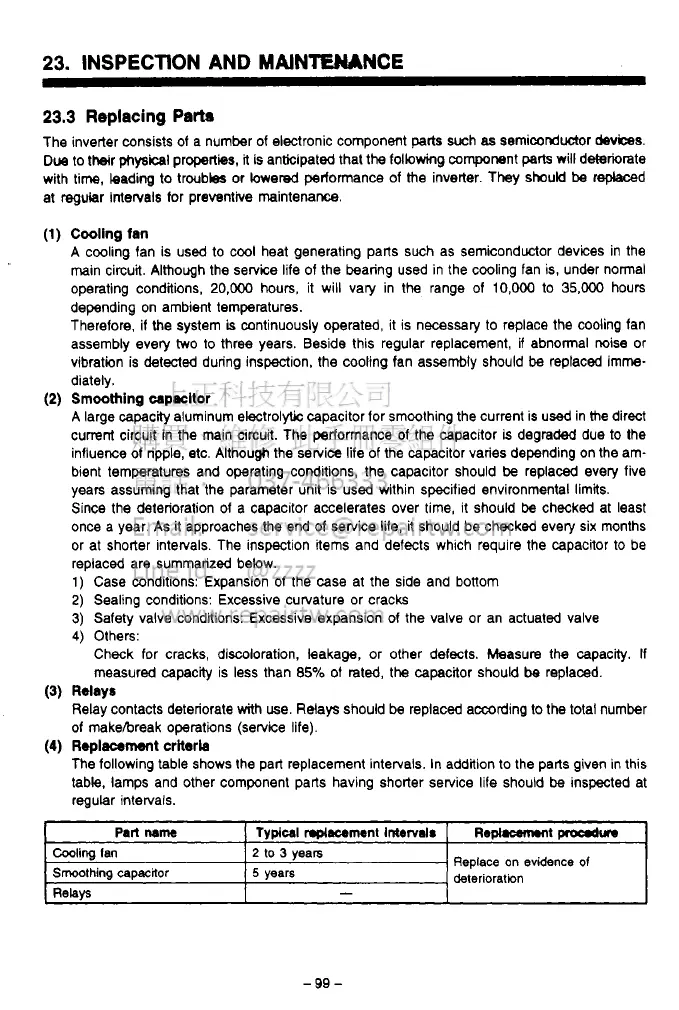

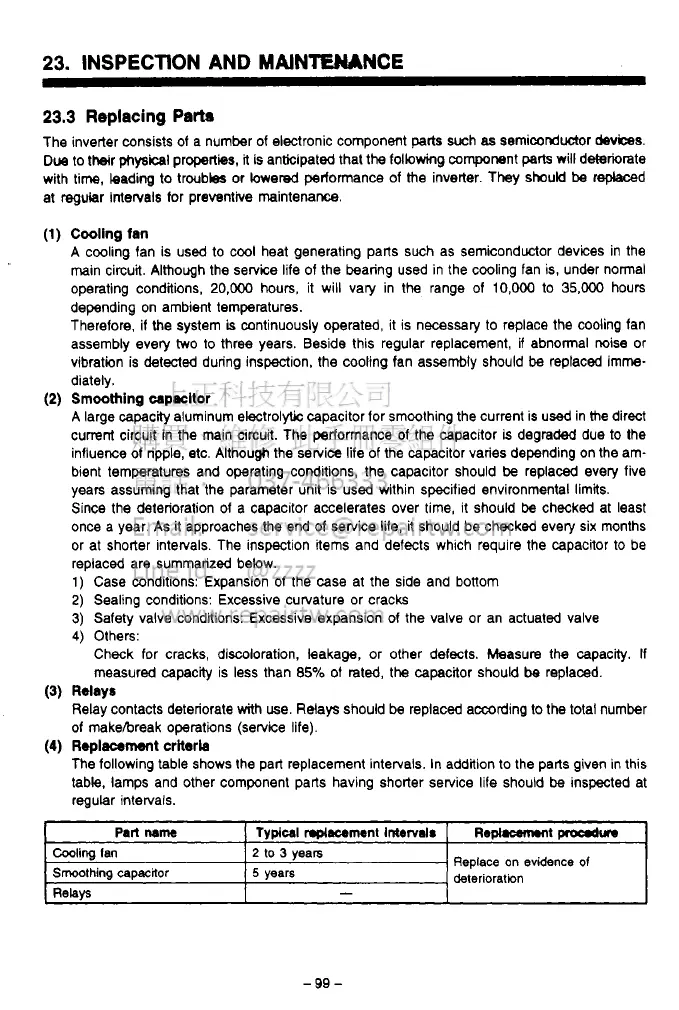

The following table shows the part replacement intervals. In addition to the parts given in this

table, lamps and other component parts having shorter service life should be inspected at

regular intervals.

(4)

Replacemsnt

criterb

I

Part

name

I

Typlcal

nplllcrment

Intervals

[

Ropl-t

proodur

Cooling

Ian

Smoothing

capacitor

2

to

3

years

-

RelaV5

Replace

on

evidence

of

deterioration

5

years

-99-

.

..

Loading...

Loading...