-

,

_.

,.l.l

._

.

..-

..

-

.

.

.

.

.

.

.I.

..

..

..

.

,..”..

.

,

,

22.

PARAMETERS

Pr.70

-

Pr.72

0

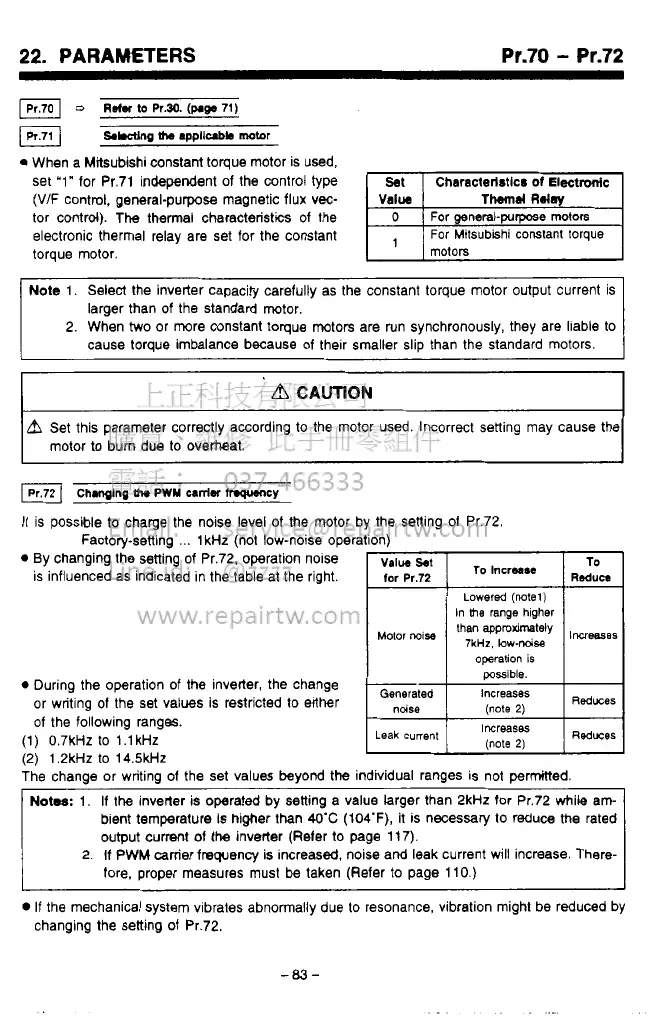

When a Mitsubishi constant torque motor is used,

set ‘1” for Pr.71 independent of the control type

(V/F control, general-purpose magnetic flux vec-

tor control). The thermal characteristics of the

electronic thermal relay are set for the constant

torque motor.

Note 1. Select the inverter capacity carefully as the constant torque motor output current is

larger than

of

the standard motor.

2. When

two

or more constant toque motors are run synchronously, they are liable to

cause torque imbalance because of their smaller slip than the standard motors.

__

d

CAUTION

A

Set this parameter correctly according to the motor used. Incorrect setting may cause the

motor to burn due to overtteat.

Chmglng

th.

PWY

=niW

hWUlCY

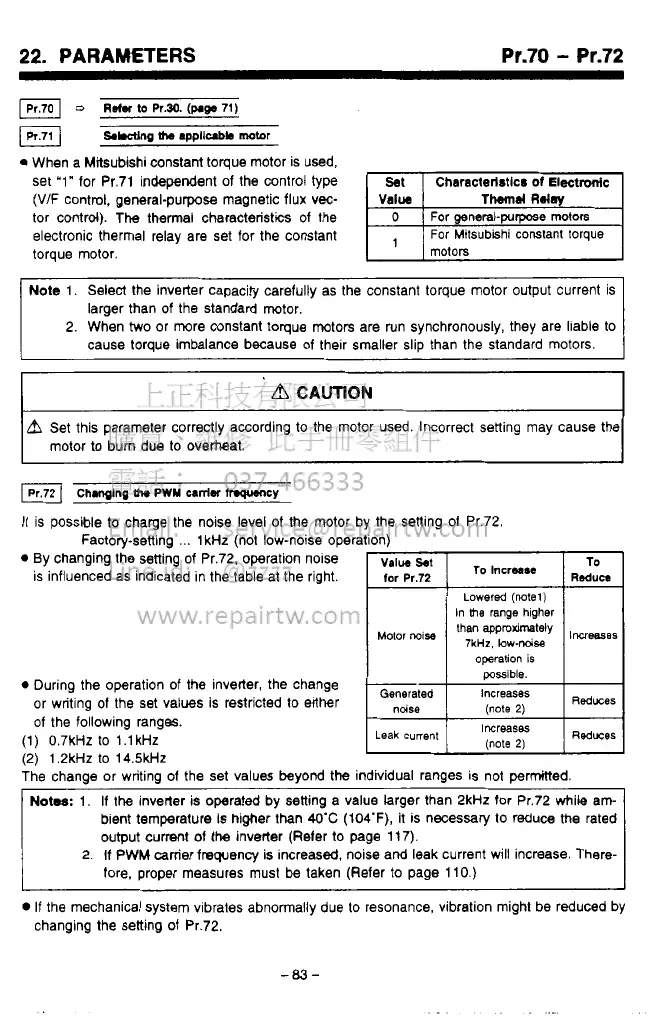

It is possible to charge the noise level

of

the motor b

Factory-setting

...

1kHz (not low-noise opera

0

By changing the setting

of

Pr.72, operation nolse

is influenced as indicated in the table at the right.

0

During the operation of the inverter, the change

or writing

of

the set values is restricted to either

of

the following ranges.

(1) 0.7kHZ to l.lkHz

f2)

1.2kHz to 14.5kJ-k

the setting

of

Pr.72.

possible.

The chanae or writing of the set values

beyond

the individual ranges is not permitted.

\,

Notes:

1.

If

the inverler is operated by setting a value larger than 2kHz for Pr.72 while am-

bient temperature

is

higher than

WC

(104‘F),

it is necessary to reduce

the

rated

output

current

of

the inverter (Refer to page 11 7).

2.

If

PWM carrier frequency is increasd, noise and leak current will increase. There-

fore, proper measures must

be

taken (Refer

to

page 110.)

0

If

the mechanical system vibrates abnormally due to resonance, vibration might be reduced by

changing the setting

of

Pr.72.

-03-

Loading...

Loading...