PURY-HP-T(S)KMU,-Y(S)KMU (September 2014)

H2i-R2-5

© 2014 Mitsubishi Electric US, Inc.

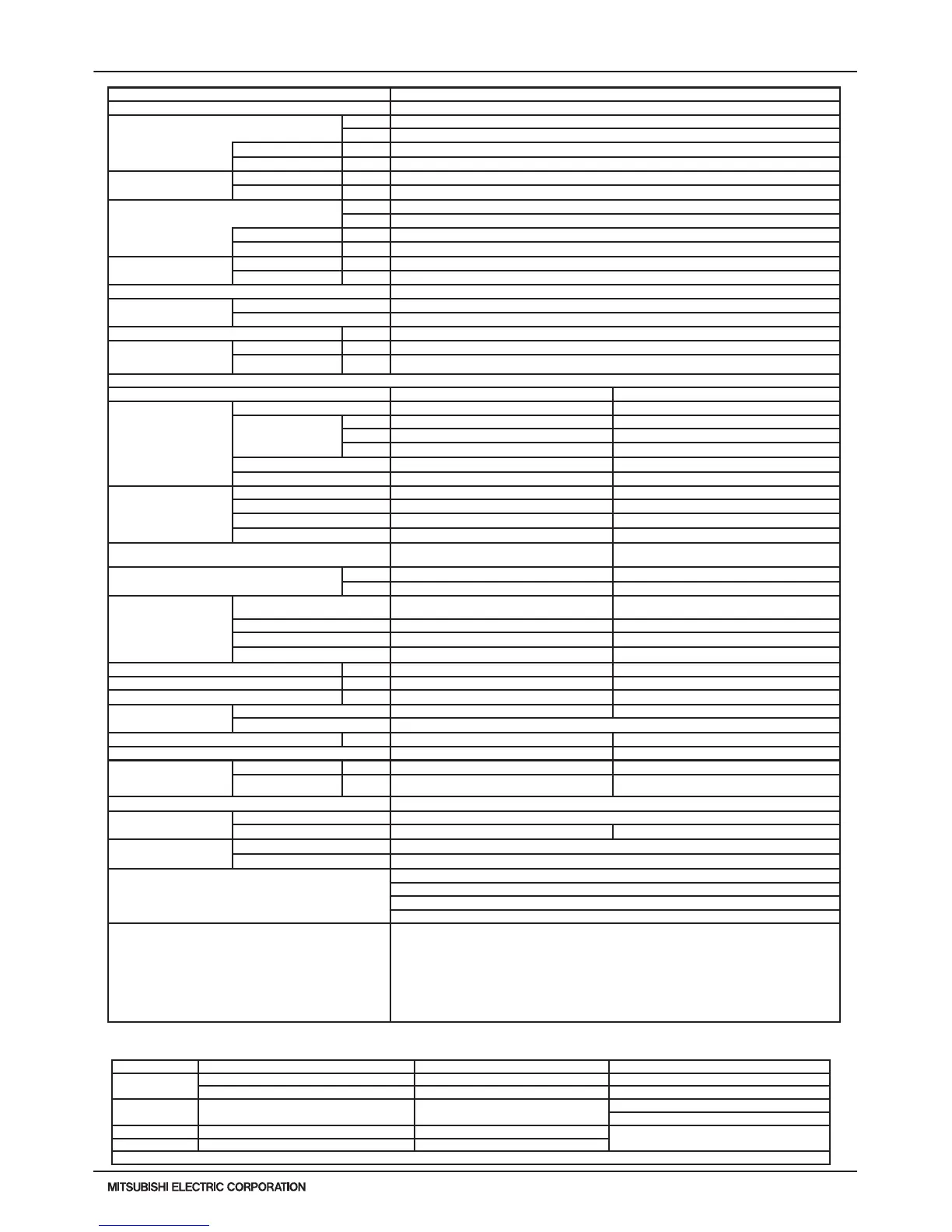

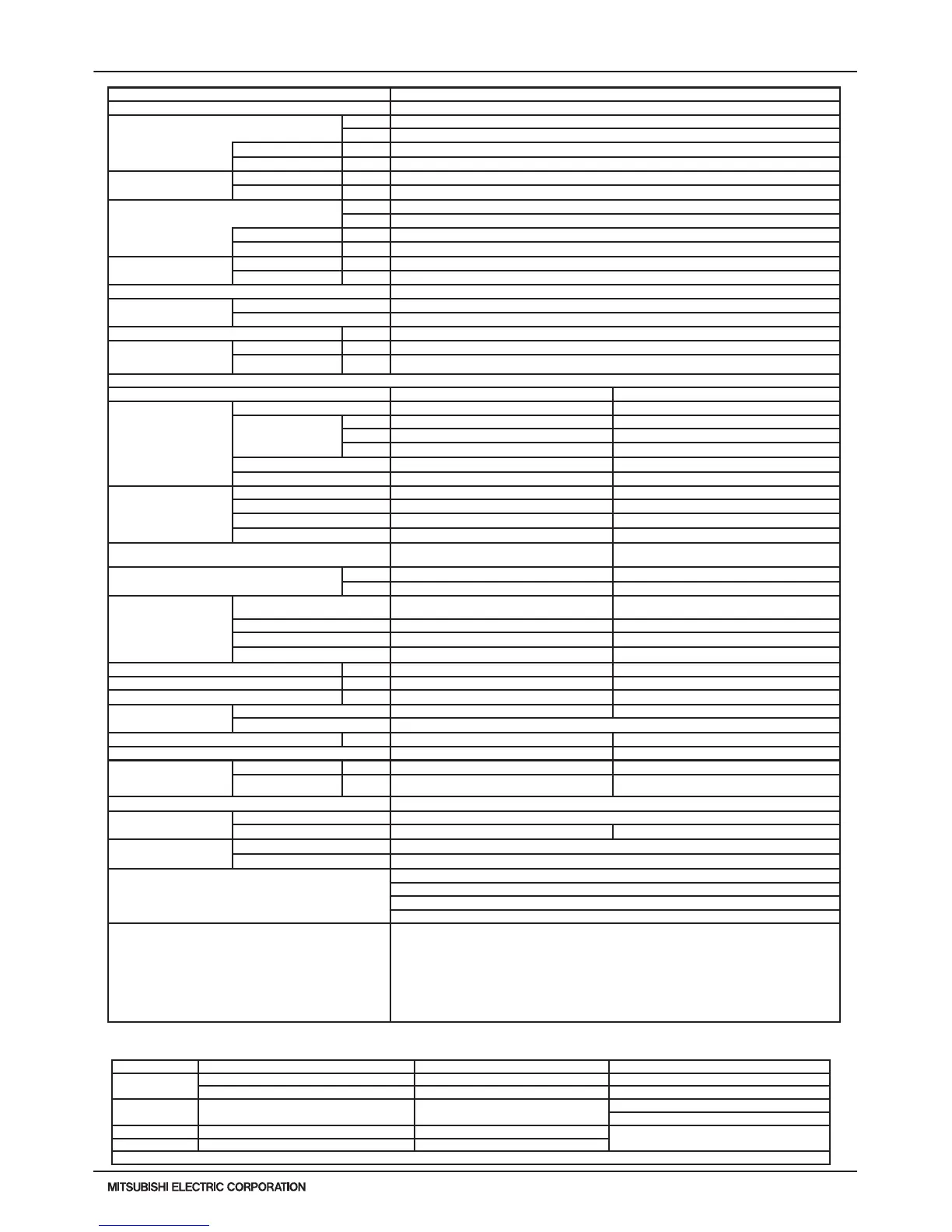

1. SPECIFICATIONS

Model PURY-HP144TSKMU-A-H

Power source 3-phase 3-wire 208 / 230V ±10% 60Hz

Cooling capacity (Nominal) *1 (208 / 230V)

Btu/h 144,000

kW 42.2

Power input

kW 10.85 *4

Current input

A 33.4 / 30.2 *4

Temp. range of cooling *3

Indoor

W.B. 59 ~ 75° F(15 ~ 24° C)

Outdoor

D.B. 23 ~ 115° F (-5 ~ +46° C) *5

Heating capacity (Nominal) *2 (208-230V)

Btu/h 160,000

kW 46.9

Power input

kW 13.16 *4

Current input

A 40.5 / 36.7 *4

Temp. range of heating *3

Indoor

D.B. 59~81°F(15~27°C)

Outdoor

W.B. -13~60°F(-25~15.5°C)

System Compressor Operating Range Heating: 8-100%

Indoor unit

connectable

Total capacity 50~150 % of outdoor unit capacity

Model / Quantity P06~P96 / 1~36

Sound pressure level (measured in anechoic room) dB <A> 61.0

Refrigerant piping

diameter from Twinning

Kit to Indoor Units

Liquid (High Pressure) In. (mm) 7/8 (22.2) Brazed

Gas (Low Pressure) In. (mm) 1-1/8 (28.58) Brazed

Set Model

Model PURY-HP72TKMU-A-H PURY-HP72TKMU-A-H

Fan

Type x Quantity Propeller fan x 1 Propeller fan x 1

Airflow rate

CFM 6,200 6,200

m

3

/ min 175 175

L/s 2,920 2,920

Control , Driving mechanism Inverter-control, Brushless DC motor Inverter-control, Brushless DC motor

External static pressure *6 0 in.WG (0 Pa) *6 0 in.WG (0 Pa) *6

Compressor

Type x Quantity Inverter scroll hermetic compressor x 1 Inverter scroll hermetic compressor x 1

Manufacturer AC&R Works, MITSUBISHI ELECTRIC CORP. AC&R Works, MITSUBISHI ELECTRIC CORP.

Starting method Inverter Inverter

Lubricant MEL32 MEL32

External finish

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

Pre-coated galvanized steel sheet

<MUNSELL 5Y 8/1 or similar>

External dimension H x W x D

In. 64-31/32 x 48-1/16 x 29-15/16 64-31/32 x 48-1/16 x 29-15/16

mm 1,650 x 1,220 x 760 1,650 x 1,220 x 760

Protection

devices

High pressure protection

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

High pressure sensor, High pressure switch at

4.15MPa (601 psi)

Inverter circuit (COMP. / FAN)

Over-heat protection,Over-current protection Over-heat protection,Over-current protection

Compressor Over-heat protection Over-heat protection

Fan Motor Thermal switch Thermal switch

Minimum Circuit Ampacity (MCA) A 44 / 40 44 / 40

Recommended Fuse/Breaker Size A 50 50

Maximum Fuse Size A 60 60

Refrigerant

Type x original charge R410A x 26 lbs + 1 oz (11.8 kg) R410A x 26 lbs + 1 oz (11.8 kg)

Control LEV and HIC circuit

Net weight lbs (kg) 552 (250) 552 (250)

Heat exchanger Salt-resistant cross n & copper tube Salt-resistant cross n & copper tube

Refrigerant piping

diameter from Module to

Twinning Kit

Liquid (High Pressure) In. (mm) 5/8”(15.88)Brazed 5/8”(15.88)Brazed

Gas (Low Pressure) In. (mm) 3/4”(19.05)Brazed 3/4”(19.05)Brazed

Defrosting method Auto-defrost mode (Reversed refrigerant cycle)

Drawing

External KJ94G492

Wiring KE94C883 KE94C883

Standard attachment

Document Installation Manual

Accessory Details refer to External Drw

Optional parts

Outdoor Twinning kit: CMY-Y100CBK2

Joint: CMY-Y102SS-G2,CMY-Y102LS-G2,CMY-Y202S-G2,CMY-R160C-J

Main BC controller: CMB-P108,1010,1013,1016NU-GA,1016NU-HA

Sub BC controller: CMB-P104,108NU-GB,CMB-P1016NU-HB

Remark

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and

other items shall be referred to the Installation Manual.

*3 Harsh weather environments may demand performance enhancing equipment.

Ask your Mitsubishi Electric representative for more details on your region.

*4 For details on the electrical data needed for installing these units,

see the H2i R2-Series System Design section.

*5 For details on extended ambient cooling operation range down to -10°FDB (-23°CDB),

see Low Ambient Cooling Kit information.

*6 External static pressure is adjustable via dipswitch setting

(0.12 in.WG, 0.24 in.WG / 30Pa, 60Pa).

Note: *1 Nominal cooling conditions *2 Nominal heating conditions Unit converter

Indoor:

80degF D.B./ 67degF W.B. 70degF D.B. kcal =kW x 860

(26.7degC D.B./ 19.4degC W.B.) (21.1degC D.B.) BTU/h =kW x 3,412

Outdoor: 95degF D.B. (35degC D.B.)

47degF D.B./ 43degF W.B.

(8.3degC D.B./ 6.1degC W.B.)

cfm =m

3

/min x 35.31

lb =kg / 0.4536

Pipe length: 25ft.(7.6m) 25ft.(7.6m)

* Above specification data is subject to rounding

variation.

Level difference: 0ft.(0m) 0ft.(0m)

* Due to continuing improvement, above specifications may be subject to change without notice.

Loading...

Loading...