Parts Requiring Angle Tightening

• When tightening the following parts, use an angle wrench (ST).

• Cylinder head bolt

Before assembly, verify that no grease/oil and dust are present

on the cylinder head, cylinder block mounting face, and head

gasket. Then apply antirust oil or engine oil to the threads and

head bottoms of the head bolts.

Caution with Use of Power Tools

• The use of power tools such as pneumatic air tools is only

allowed for disassembly. Do not use them for assembly.

Precautions for Liquid Gasket Application

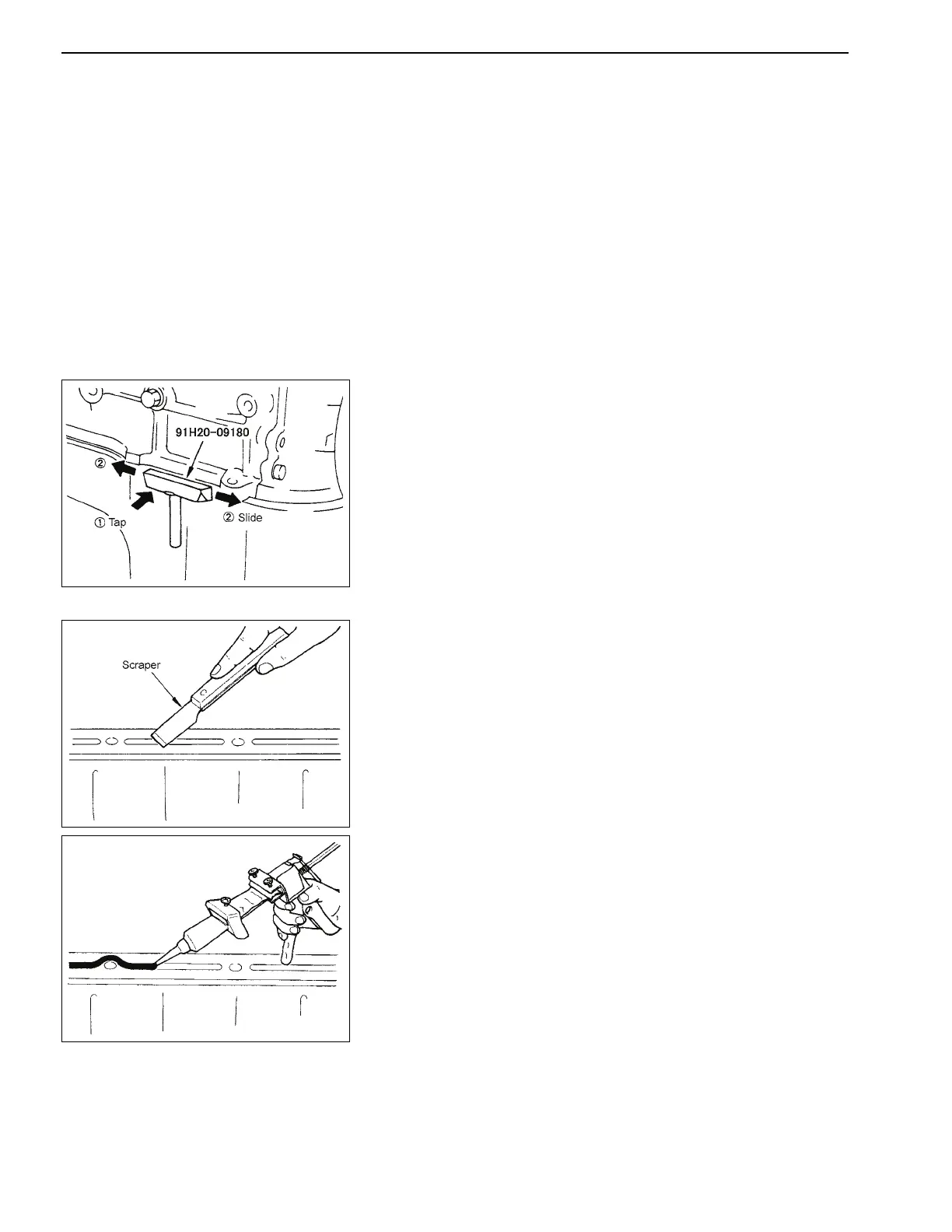

REMOVING PARTS ATTACHED WITH LIQUID GASKET

• Remove mounting nuts and bolts. Remove liquid gasket using a

seal cutter (ST).

Be careful not to damage the mating surfaces.

• In positions where a seal cutter is difficult to use, lightly tap with

a plastic hammer, and remove.

Be careful not to scratch the mating surfaces when using a

screwdriver.

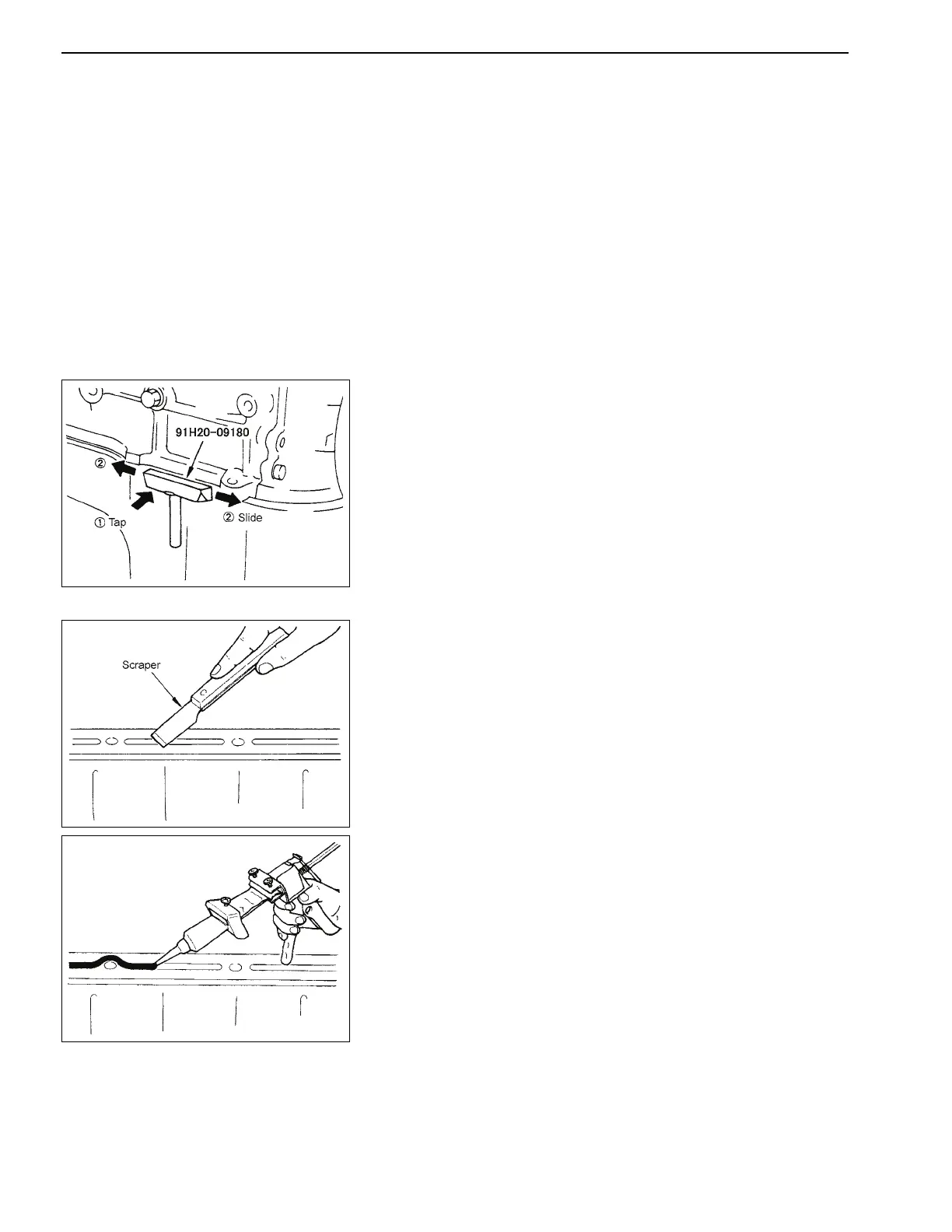

LIQUID GASKET APPLICATION INSTRUCTION

1. Remove any old liquid gasket remaining on the gasket

application surface and its mating surface using a scraper.

• Remove any old liquid gasket remaining in the gasket

application groove and on the threads of bolts and bolt

holes.

2. Wipe the gasket application surface and its mating surface

using Isozole or any equivalent thinner to remove any moisture,

oil, and foreign material.

3. Set genuine liquid gasket to tube presser (commercial service

tool).

4. Apply a continuous bead of liquid gasket to the specified

position at the specified diameter.

• Apply liquid gasket in the application groove.

• Apply liquid gasket inside bolt holes as a rule. Make sure to

carefully read the relevant instructions.

• Attaching should be done within 5 minutes after gasket

application.

• Immediately wipe off any protruding liquid gasket.

• Do not retighten nuts and bolts after installation.

• After finishing work, wait at least 30 minutes before refilling

engine oil and coolant.

Follow any directions specified in the text on the following

pages.

GI-6

PRECAUTIONS

Loading...

Loading...