73

MECHANICAL STRUCTURE

1 Apply the lithium grease to the bush of the front and rear brackets for assembly.

2 Screw and crimp the nut in the condition which the front bracket is set with slight backlash, none

excessive.

3 Apply the adhesives equivalent to Threebond #1782 to the breather pipe and press it.

4 Assembly of Pinion Shaft

1. Adjust the preload for pinion shaft within 0.39 to

1P^WRNJIFPWROEIIW`DWRLO

seal assembling) by tightening the nut.

Crimp the nut after adjustment.

2. Measure the distance H

and determine the thickness

of liners as follows.

Liner thickness = H-16mm {0.63in}

3. Placing direction of the oil seal for pinion shaft

shall be as shown in the figure. (Spring stays

inside.)

(Unit: mm {in})

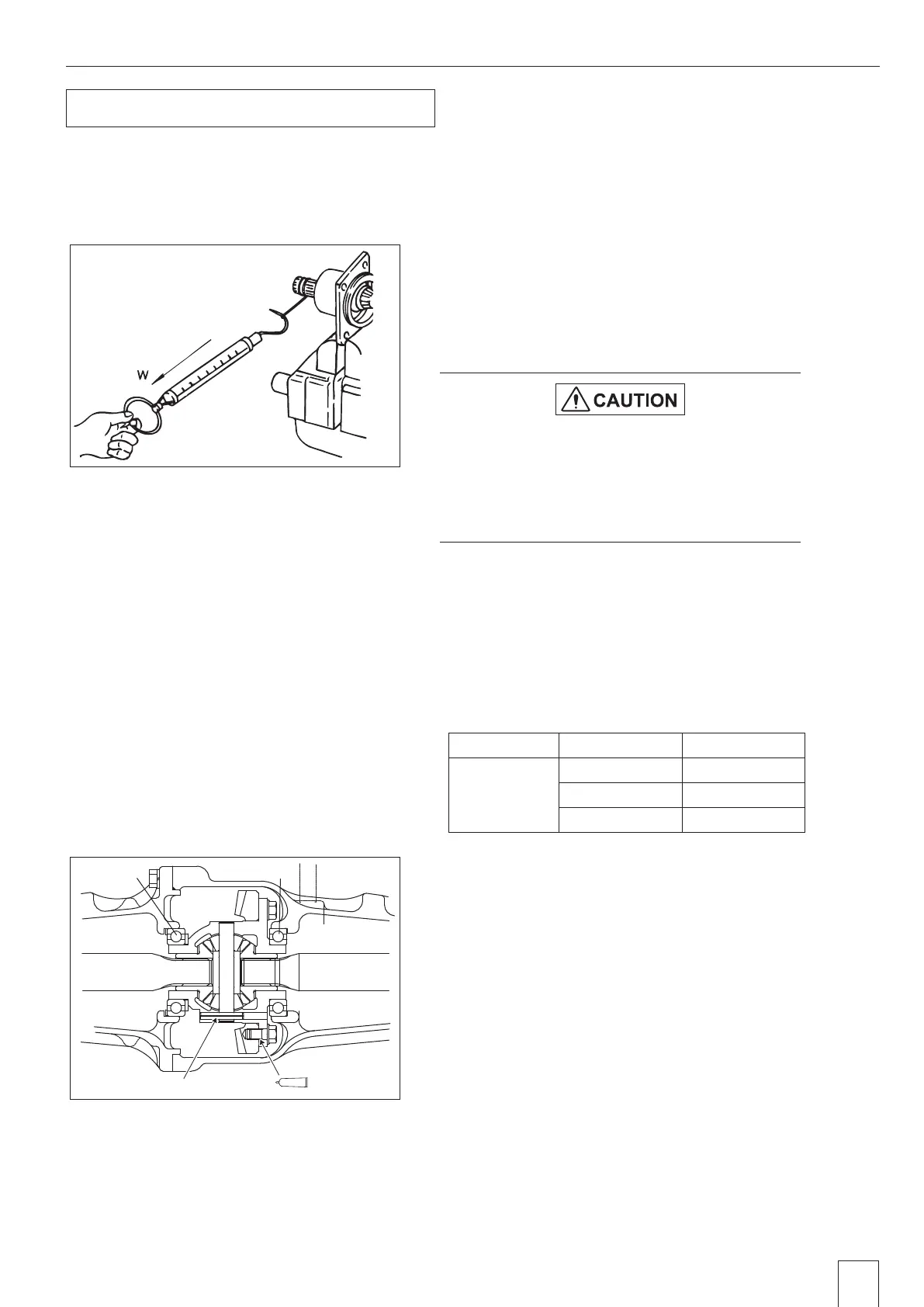

5 Assembly of Differential Case Assembly

1. Make sure the backlash for the pinion gear and side

gear is within 0.10 to 0.30mm {0.004 to 0.012in}.

2. Apply the adhesives equivalent to Threebond #1374

thto

to

e locking bolt for the ring gear and tighten with

WRUTXHDWWR1P^WR NJIFP

OEIIW`

3. Place the spring pin with the slit toward as shown in

the figure. (Vertical to the shaft)

4.

Apply the lubricant (MOS

2

) to the gears and assemble

it.

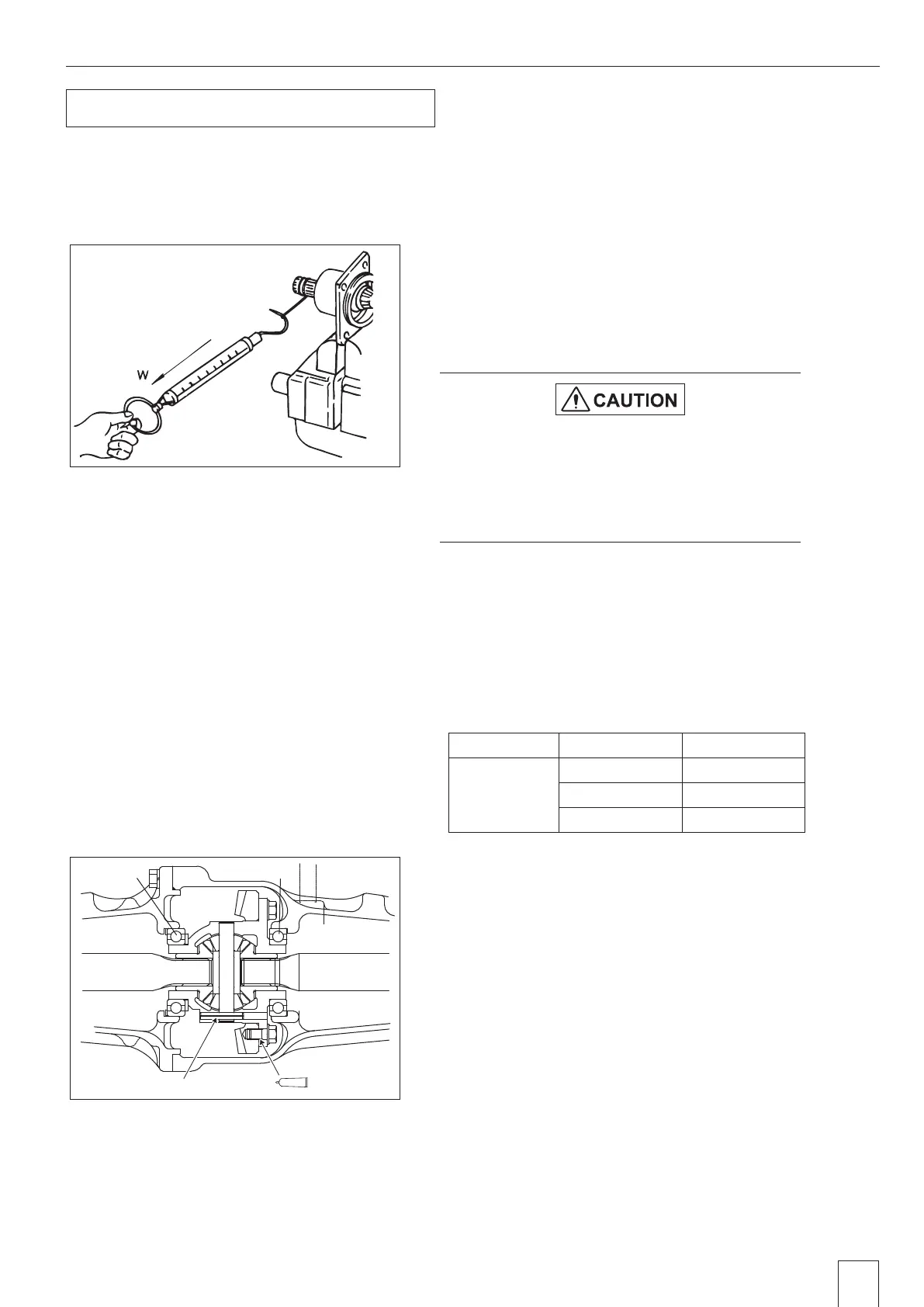

As an easier method for measuring the preload,

after temporarily tightening the nut, wind the shaft

of pinion shaft with rope and pull with spring

balance. (F = 39.2 to 58.8N {4.0 to 6.0kgf, 8.8 to

13.2lbf})

Item Thickness Usable Limit

Liner "J"

0.10 {0.004} 1023 2136 001

0.20 {0.008} 1023 2137 001

0.40 {0.016} 1023 2138 001

GS7W3-167

Spring pin

Bond

GZ3W26-021

6010

6010

1. Assembly of Front Axle

Loading...

Loading...