74

MECHANICAL STRUCTURE

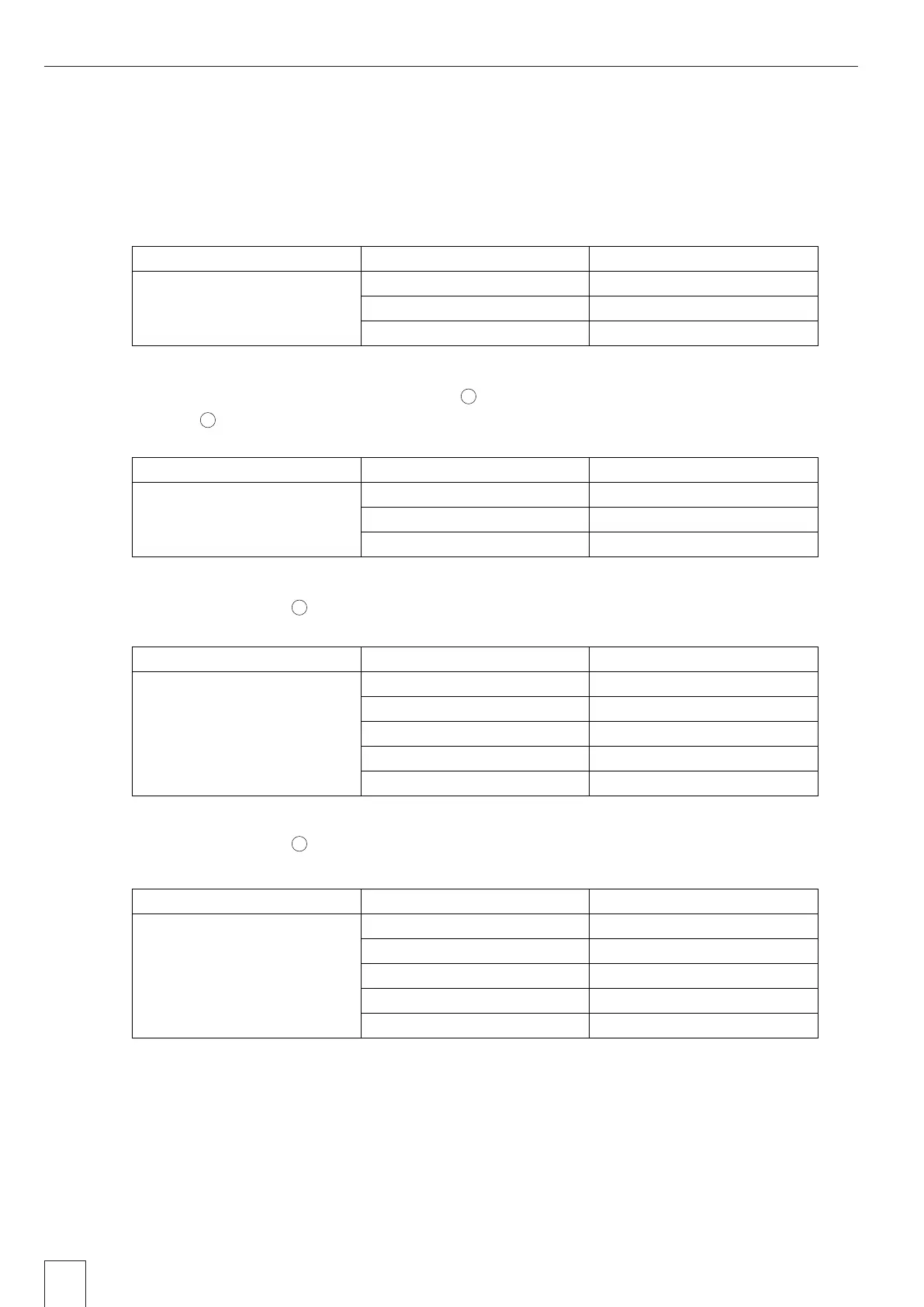

6 Installation of Differential Case Assembly

1. Adjust the backlash for pinion shaft and differential ring gear to be within 0.25 to 0.35mm {0.01 to 0.014in}

with the liner "A".

2. After adjusting the backlash, adjust the lateral backlash for differential case assembly to be within 0 to 0.10mm

{0 to 0.004in} with the liner "B".

(Unit: mm {in})

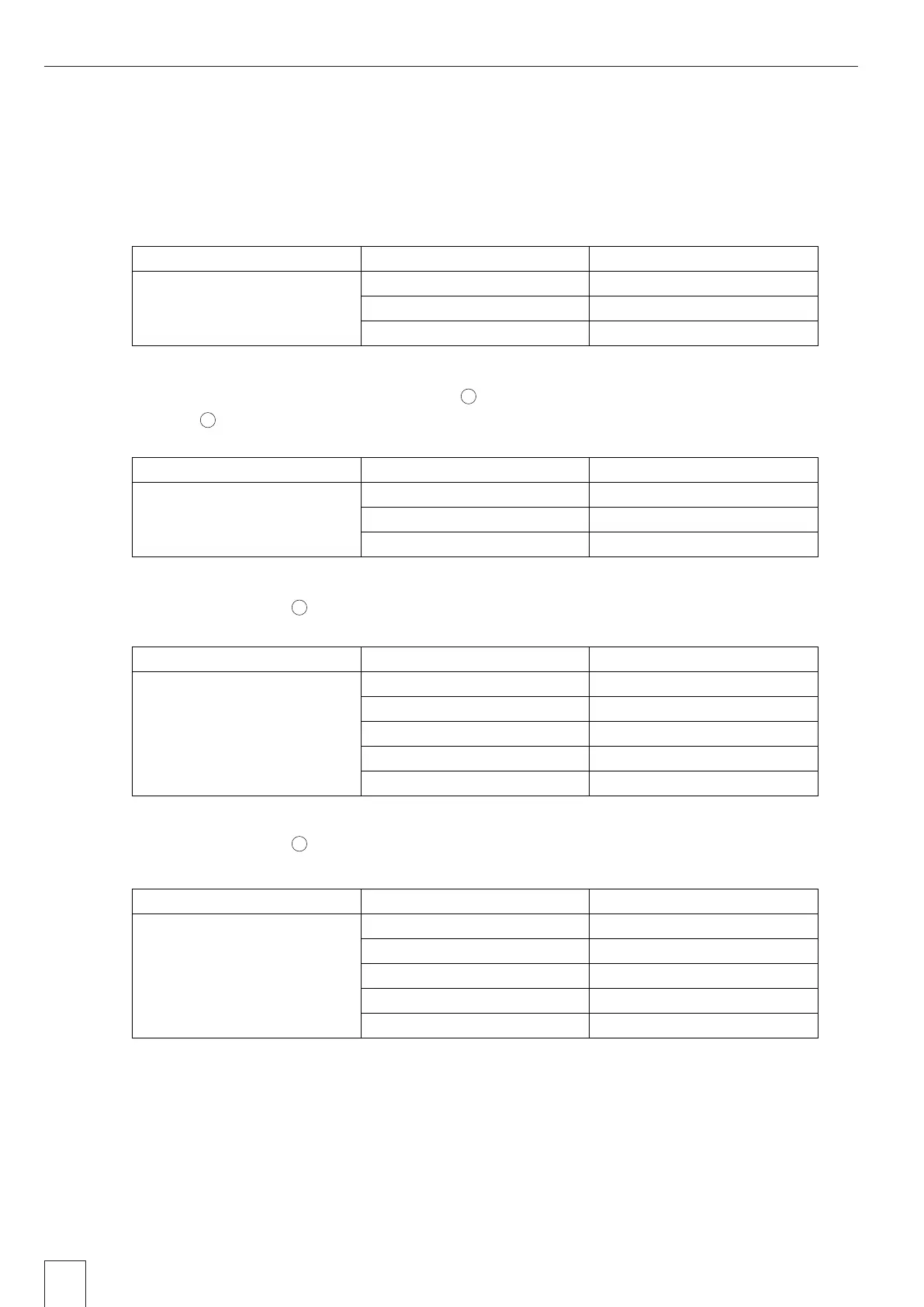

7 Assembly of Kingpin

1. Determine the thickness of liner "G" that dimension becomes 11.0±0.05mm{0.433±0.002 in} on top and

dimension becomes 17.9±0.05mm{0.705±0.002 in} on bottom.

(Unit: mm {in})

2. Assemble with caution not to turn over the lip of the oil seal.

3. Adjust so that dimension may become 25±0.5mm {0.98±0.002 in} by inserting or removing the liner "C".

(Unit: mm {in})

8 Assembly of Axle Shaft

(Unit: mm {in})

2. Adjust the lateral clearance "E" for axle shaft to be within 0 to 0.20mm {0 to 0.008in} with the liner "E".

3. Apply the liquid packing (Threebond #1208D) to the holder and cover. Wrap the mounting bolt with seal

tape and tighten.

Item Thickness Usable Limit

Liner "A" and "B"

0.10 {0.004} 1007 0618 000

0.20 {0.008} 1007 0618 100

0.40 {0.016} 1007 0618 200

Item Thickness Usable Limit

Liner "G"

0.15 {0.006} 0730 0005 201

0.20 {0.008} 0730 0005 202

0.30 {0.012} 0730 0005 203

Item Thickness Usable Limit

Liner "C"

0.075 {0.003} 67700-30300

0.40 {0.016} 0731 0003 004

0.80 {0.031} 0731 0003 008

1.00 {0.039} 0731 0003 010

1.20 {0.047} 0731 0003 012

Item Thickness Usable Limit

Liner "D"

0.15 {0.006} 0731 0003 001

0.40 {0.016} 0731 0003 004

0.80 {0.031} 0731 0003 008

1.00 {0.039} 0731 0003 010

1.20 {0.047} 0731 0003 012

A

C

1. Adjust so that dimension may become 3±0.5mm {0.12±0.002 in} by inserting or removing the liner "D".

D

B

Loading...

Loading...