86

MECHANICAL STRUCTURE

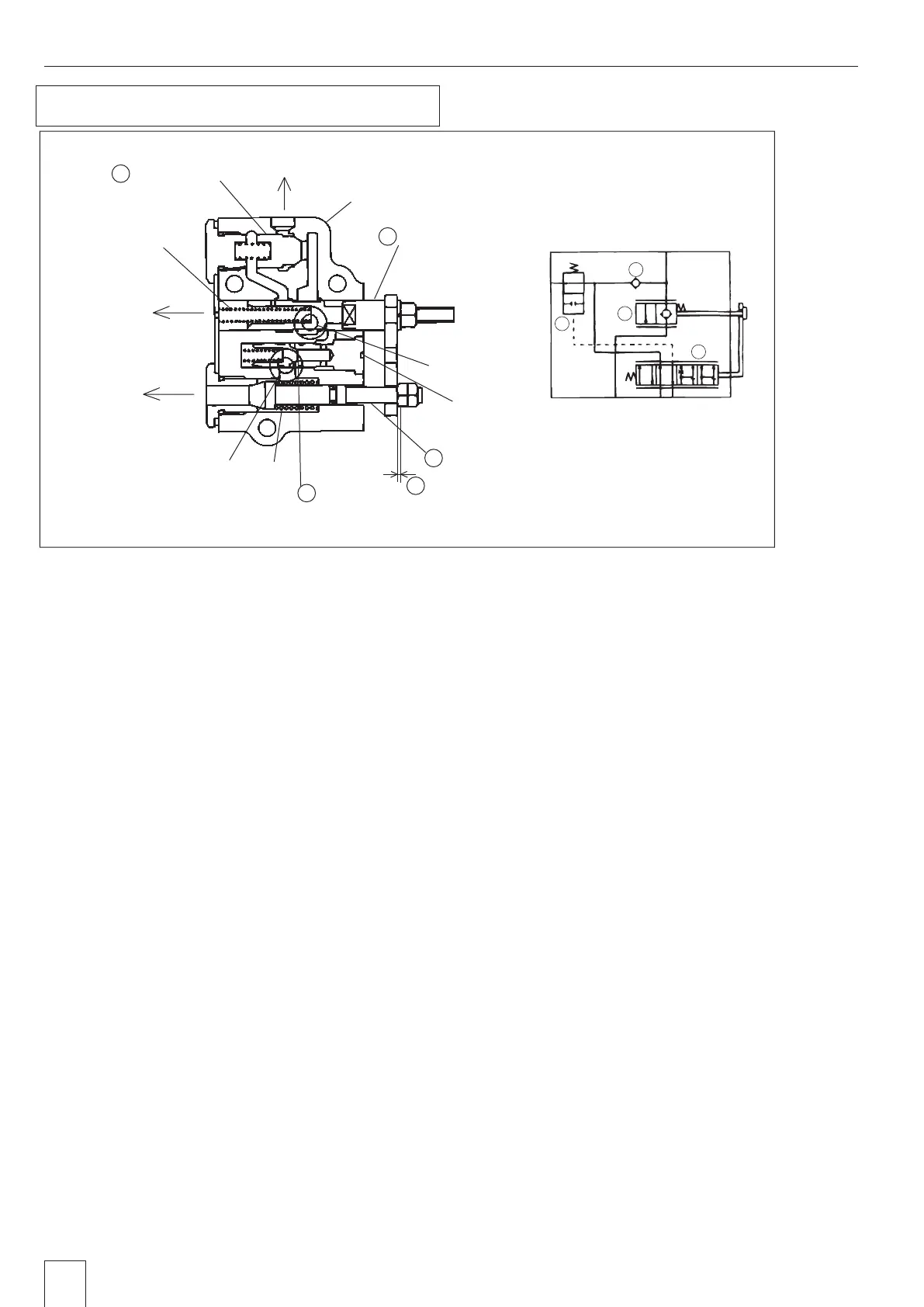

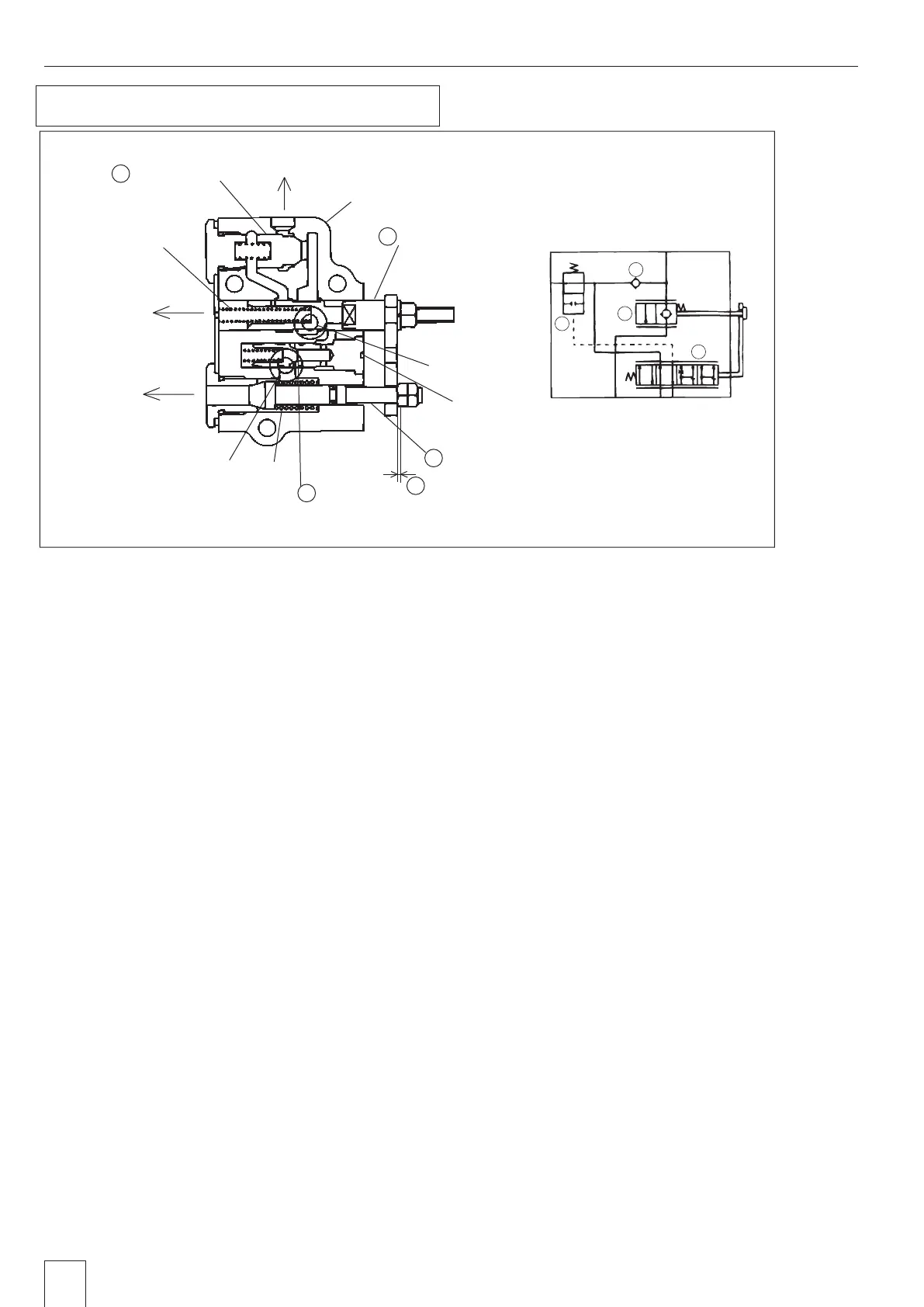

4 Assembly of Control Valve

1. Assembling Procedure

1) Line up all the parts disassembled and check the O-ring for scratches and wears. If any defects, change it.

2) Check the spool, movement of plunger, and sheet part for any

flaws

. If any flaws, smooth them with

oilstone.

3) Clean with cleaning fluid.

4) Make sure the assembling position and direction at assembly.

5) Apply some grease to O-ring when assembling it.

2. Adjusting Procedure

1) Remove the plug and the spring of unload valve.

2) The position, which changes the sound when moving the spool while blowing in the air from the

plug, is

the neutral position for the spool.

3) Set the clearance "T" with the nut connecting the plate and poppet within 0.3 to 0.6mm {0.012 to 0.024in}

in this position and lock.

Hydraulic

pressure signal

T

2

T1 P

C

T3

4

3

2

1

Neutral oil return

Valve body

Spool valve

Pump port

Poppet

Check valve

Poppet

spring

Cylinder port

Control Valve Sectional View

Cylinder return

Pilot oil return

Spool valve

spring

Unload valve

4

2

T 0.3 - 0.6mm

1

3

Sheet

GZ3W31-024A

4. Assembly of Control Valve

Loading...

Loading...