17. FULLY CLOSED LOOP SYSTEM

17 - 13

(5) Setting of feedback pulse electronic gear

POINT

If an incorrect value is set in the feedback pulse electronic gear ([Pr. PE04], [Pr.

PE05], [Pr. PE34], and [Pr. PE35]), [AL. 37 Parameter error] and an abnormal

operation may occur. Also, it may cause [AL. 42.8 Fully closed loop control error

by position deviation] during the positioning operation.

The numerator ([Pr. PE04] and [Pr. PE34]) and denominator ([Pr. PE05] and [Pr. PE35]) of the electronic

gear are set to the servo motor-side encoder pulse. Set the electronic gear so that the number of servo

motor encoder pulses per servo motor revolution is converted to the number of load-side encoder

pulses. The relational expression is shown below.

[Pr. PE04] × [Pr. PE34]

[Pr. PE05] × [Pr. PE35]

Number of motor encoder pulses per servo motor revolution

Number of load side encoder pulses per servo motor revolution

=

Select the load-side encoder so that the number of load-side encoder pulses per servo motor revolution

is within the following range.

4096(2

12

) ≤ Number of load-side encoder pulses per servo motor revolution ≤ 67108864 (2

26

)

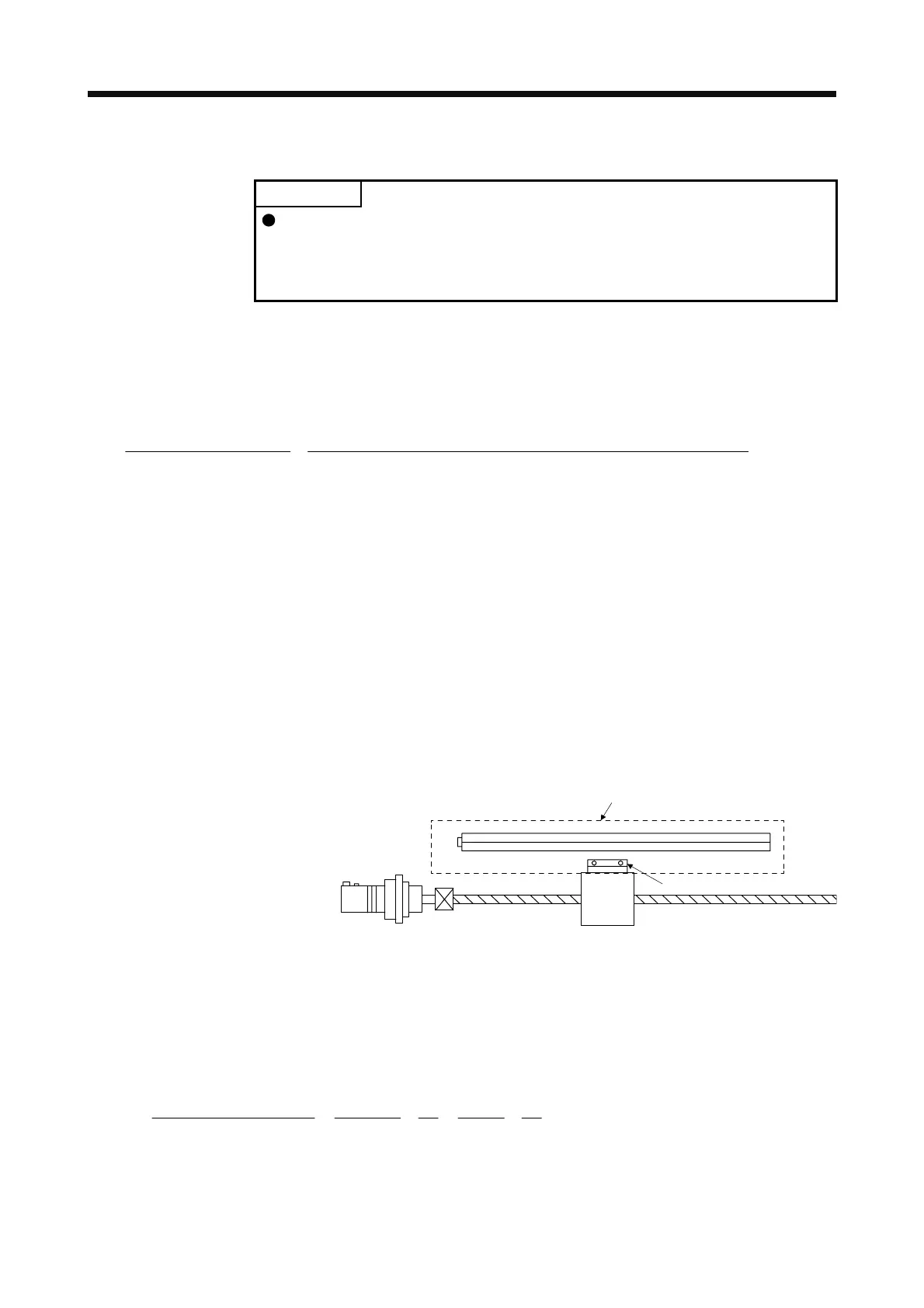

(a) When the servo motor is directly coupled with a ball screw and the linear encoder resolution is 0.05

μm

Conditions

Servo motor resolution: 4194304 pulses/rev

Servo motor reduction ratio: 1/11

Ball screw lead: 20 mm

Linear encoder resolution: 0.05 µm

Geared servo motor

Table

Linear encode

Linear encoder head

Calculate the number of linear encoder pulses per ball screw revolution.

Number of linear encoder pulses per ball screw revolution

= Ball screw lead/linear encoder resolution

= 20 mm/0.05 µm = 400000 pulses

[Pr. PE04] × [Pr. PE34]

[Pr. PE05] × [Pr. PE35]

400000

4194304

3125

32768

1

11

=

1

11

=××

Loading...

Loading...