6 - 70

MELSEC-Q

6 SEQUENCE PROGRAM USED FOR POSITIONING CONTROL

6.5.6 Stop program

The axis stop signal [Y4, Y5, Y6, Y7] or a stop signal from an external source is used

to stop the control.

Create a program to turn ON the axis stop signal [Y4, Y5, Y6, Y7] as the stop program.

The process for stopping control is explained below.

Each control is stopped in the following cases.

(1) When each control is completed normally.

(2) When the Servo READY signal is turned OFF.

(3) When the PLC READY signal is turned OFF.

(When a stop error such as "parameter error" or "watch dog timer error" occurs in

PLC CPU.)

(4) When an error occurs in QD75.

(5) When control is intentionally stopped

(Stop signal from PLC CPU turned ON, stop signal from peripheral devices)

The stop process for the above cases is shown below.

(Excluding item (1) above "When each control is completed normally".)

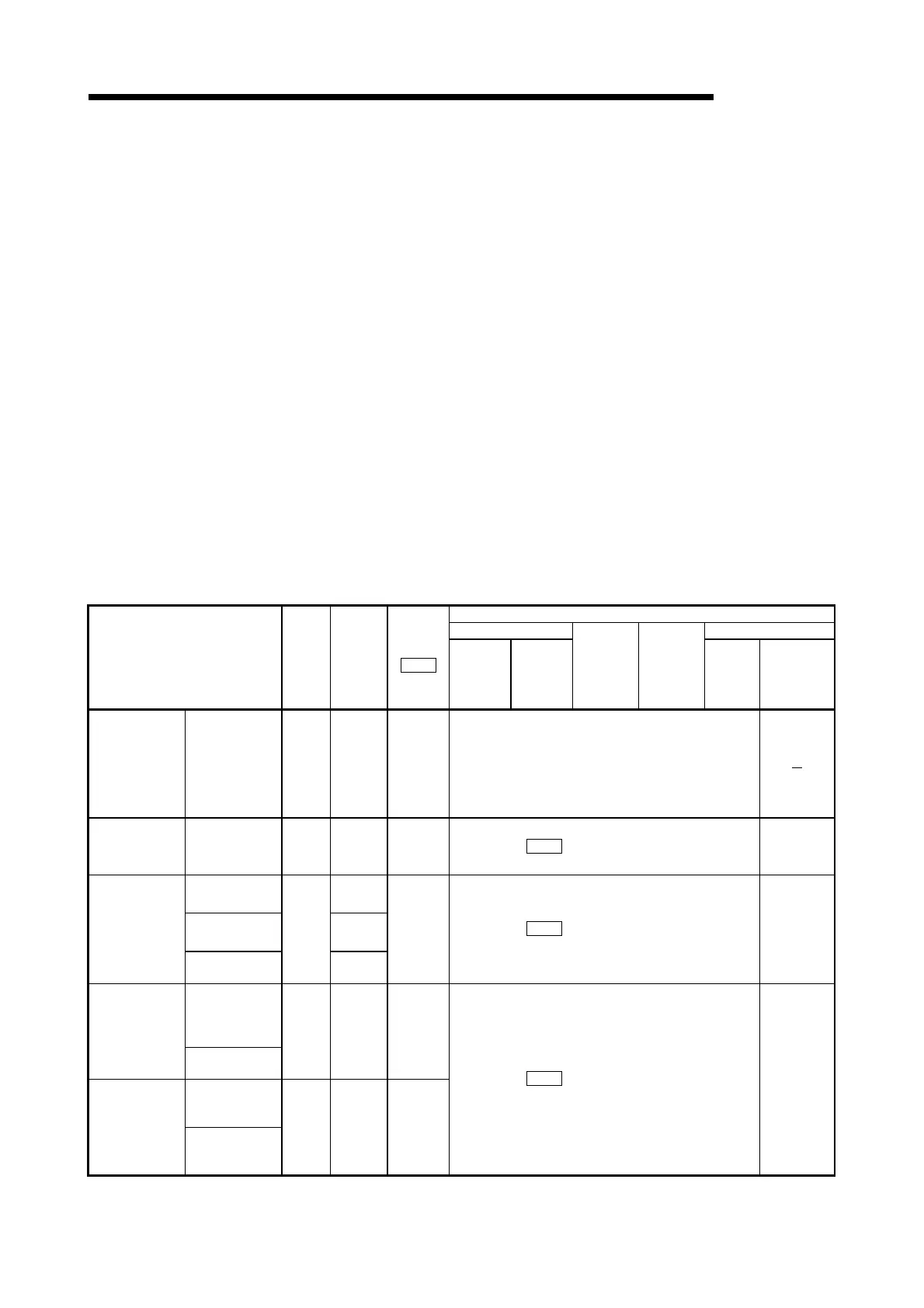

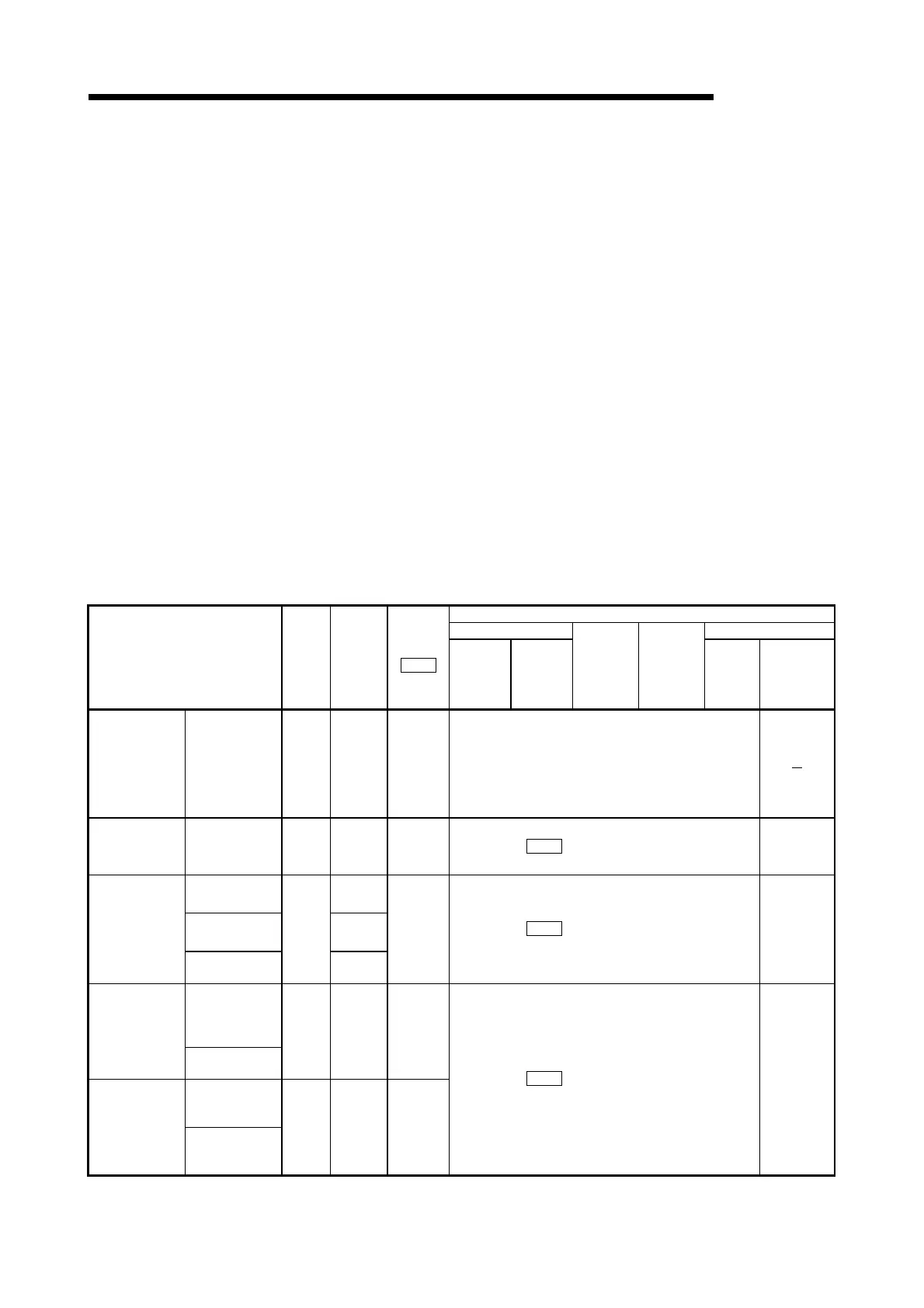

[1] Stop process

Stop process

OPR control Manual control

Stop cause

Stop

axis

M code

ON

signal

after stop

Axis

operation

status

(

Md.26

)

after

stopping

Machine

OPR

control

Fast OPR

control

Major

positioning

control

High-level

positioning

control

JOG/

Inching

operation

Manual

pulse

generator

operation

Forced stop

Servo READY OFF

• Servo amplifier

power supply

OFF

• Servo alarm

• Emergency stop

of PLC CPU

Each

axis

No

change

During

error

Servo OFF or free run

Fatal stop

(Stop group 1)

Hardware stroke

limit signal ON

Each

axis

No

change

During

error

Deceleration stop/sudden stop

(Select with "

Pr.37

Sudden stop group 1 sudden stop

selection".

Deceleration

stop

Error occurs in

PLC CPU

No

change

PLC READY

signal OFF

Turns

OFF

Emergency stop

(Stop group 2)

Error in test

mode

All axes

No

change

During

error

Delegation stop/sudden stop

(Select with "

Pr.38

Sudden stop group 2 sudden stop

selection".

Deceleration

stop

Axis error

detection (Error

other than stop

group 1 or 2)

Relatively safe

stop

(Stop group 3)

"Stop" input from

peripheral device

Each

axis

No

change

During

error

"Stop signal" ON

from external

source

Intentional stop

(Stop group 3)

"Axis stop signal"

ON from PLC

CPU

Each

axis

No

change

During

stop

(during

standing

by)

Deceleration stop/sudden stop

(Select with "

Pr.39

Sudden stop group 3 sudden stop

selection".

Deceleration

stop

Loading...

Loading...