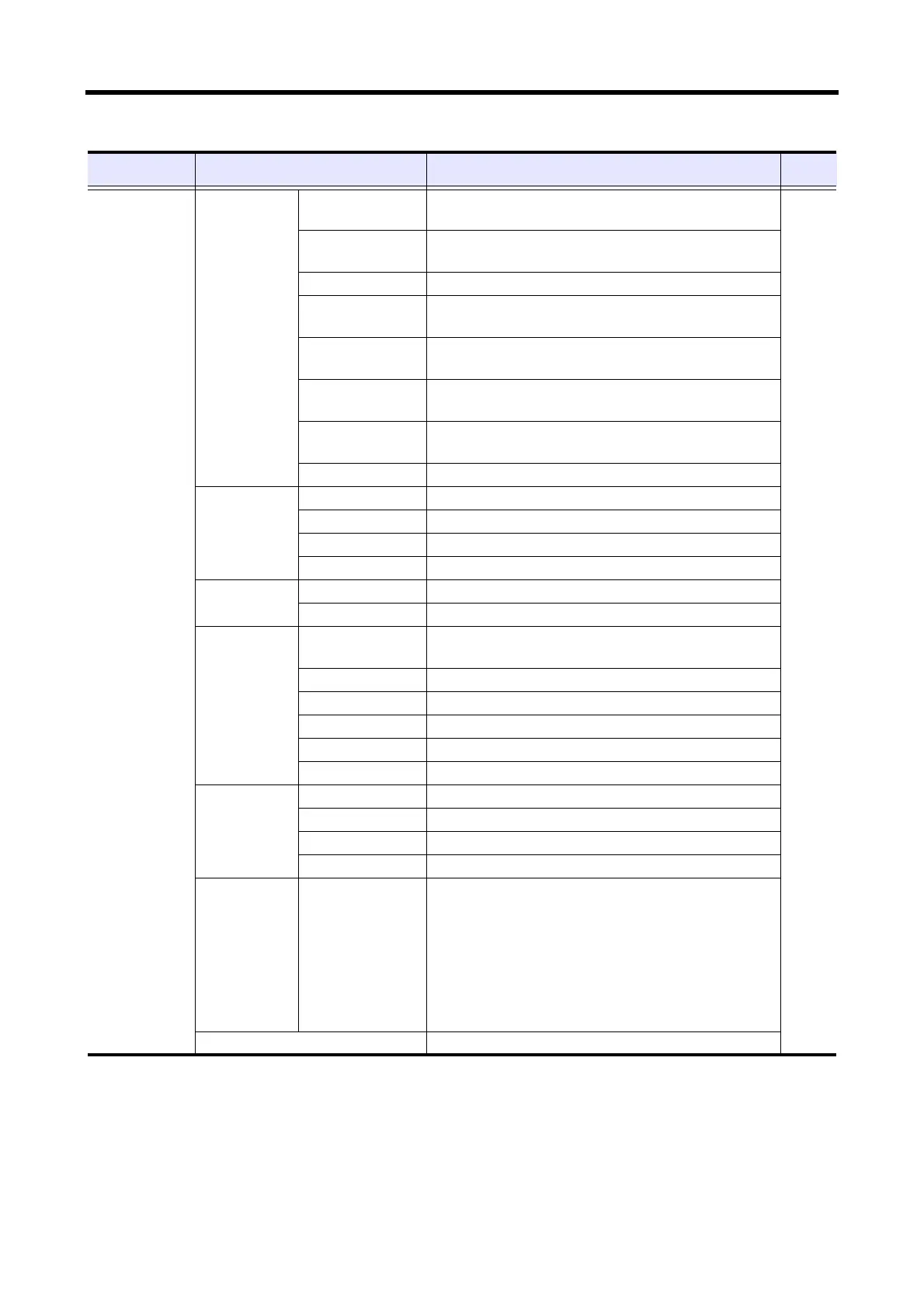

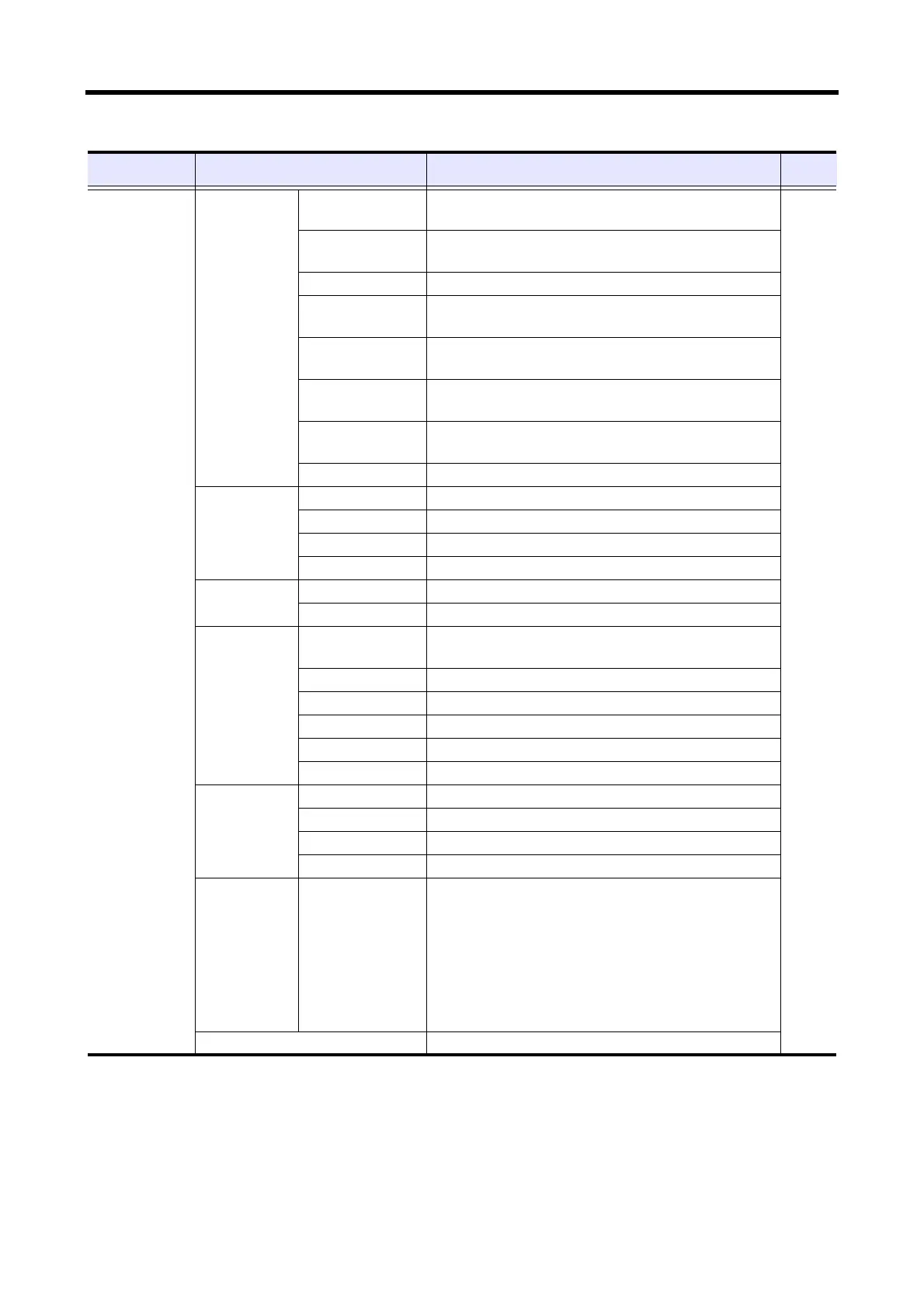

Chapter 5 PERIODIC MAINTENANCE CHART

5-6

Every 12000

service

hours

Fuel system

Fuel control

linkage

Change ball joints and ball bearings.

½

Fuel injection

pump

Disassembe and maintain, and change deflec-

tors and O-rings.

Fuel feed pump Change oil seals and O-rings.

Fuel injection

pipes

Change.

Fuel injection

timing

Inspect and adjust.

Fuel pressure

regulator valve

Inspect.

Fuel system

accumulator

Change.

Fuel pipes Change O-rings and sealing washers.

Lubricating

system

Oil pump Change bushings.

Oil cooler Inspect and clean element.

Regulator valve Disassemble and maintain.

Oil pipes Change O-rings and gaskets.

Cooling

system

Water pump Change bearings.

Coolant pipes Change O-rings.

Inlet and

exhaust

systems

Turbocharger

Remove carbon deposits and change seal rings,

bearings and expendable parts.

Air cooler Clean element.

Air cooler cover Change gaskets.

Air inlet pipes Change O-rings.

Exhaust pipes Change gaskets, bolts and nuts.

Exhaust duct Change V-clamps.

Air starter

system

Starting valve Inspect, lap and change O-rings and gaskets.

Air pipes Change gaskets.

Air tank Inspect safety valve operation.

Distributor Change valve, shaft, bushings, pins and gaskets.

Protection

device

Increasing cool-

ant tempera-

ture,

decreasing oil

pressure, over-

speed and

emergency

stop device

Inspect operation.

Flexible hoses Change.

Table 5-1 Periodic maintenance chart for engine in regular use (4 / 5)

Service

interval

Service item Service contents Page

Loading...

Loading...