Lid

Te

rminal cover

The screw of the lid

is tightened securely.

○Perform wiring, please take care of connecting the

terminal number of outdoor unit terminal block.

Terminal block

Clamp

Screw

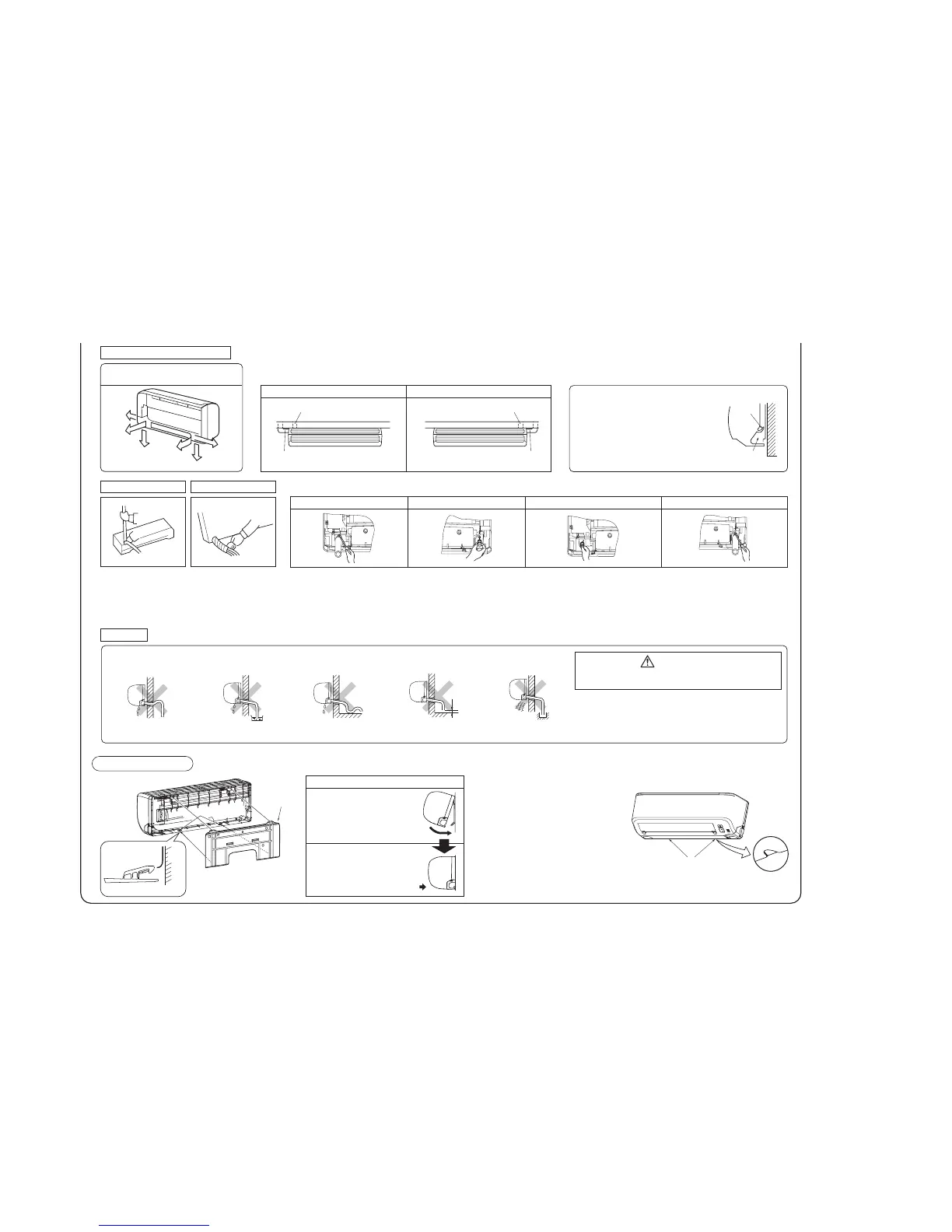

Fixing of installation board

Relation between setting plate and indoor unit

Drill a hole with whole core drill.

Thickness of the wall +1.5 cm

In case of rear piping draw out, cut off the lower

and the right side portions of the sleeve collar.

5

°

○

○

ø65

INSTALLATION OF INDOOR UNIT

Installation of Installation board

Drilling of holes and fixture of sleeve (Option parts)

Installed state

Top

●

Matters of special notice when piping from left or central/rear of the unit.

[Top view]

Left-hand-sided piping

Piping in the left rear direction

Piping in the left direction

Piping in the right direction

Piping in the right rear direction

Higher than specified

Wavy

Right

Rear

Downward

Left rear

Left

Left downward

Right-hand-sided piping

Look for the inside wall structures (Intermediate support or pillar

and firmly install the unit after level surface has been checked.)

Mating mark for

level surface

Level position (2 locations)

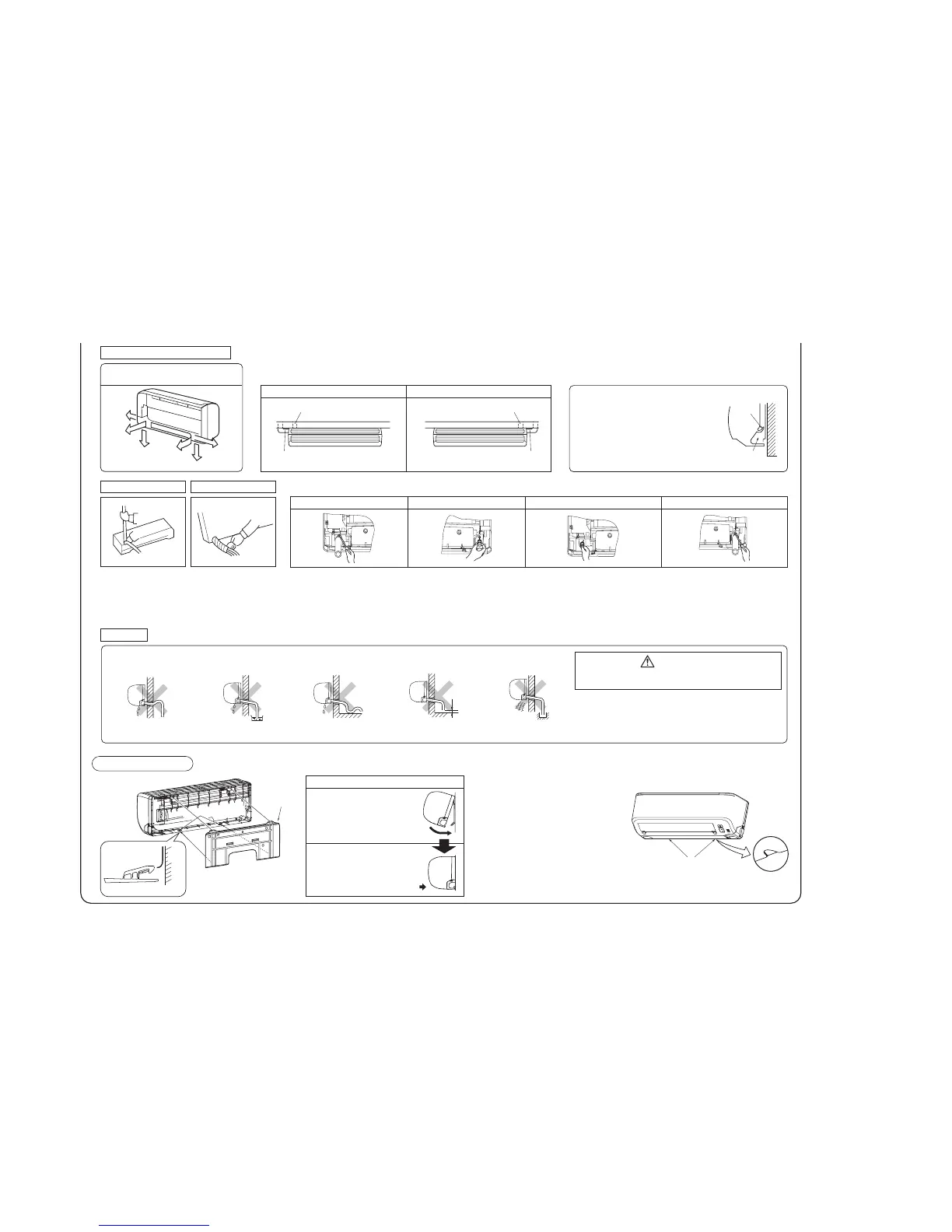

Gutter

Pipe accommodating section

Since this air conditioner has

been designed to collect dew

drops on the rear surface to

the drain pan, do not attach

the power cord above the

gutter.

RLC012A001A

When drilling the wall that contains a metal lath, wire lath or metal plate, be sure to use pipe hole sleeve sold separately.

Standard hole

○Adjustment of the installation board in the horizontal

direction is to be conducted with four screws in a

temporary tightened state.

○Adjust so the board will be level by turning the

board with the standard hole as the center.

Indoor side Outdoor side

394

The gap to the ground is

5 cm or less.

The drain hose tip is

in the gutter.

The drain hosetip is

in water.

Shaping of pipings

Taping of the exterior

Piping

Drain hose

Installing the support of piping

Drainage

○Hold the bottom of the

piping and fix direction

before stretching it and

shaping it.

○Tape only the portion that

goes through the wall.

○Always tape the wiring

with the piping.

Sufficient care must be taken not to damage the panel

when connecting pipes.

Fixing of indoor unit

Indoor unit

Installation board

W

all

Indoor unit base lower latch

L

a

t

ch

(

2

loca

t

i

on

s)

Installation

board

Installation Steps

①Pass the pipe through the hole

in the wall, and hook the upper

part of the indoor unit to the

installation board.

②Gently push the lower part to

secure the unit.

Odor from

the gutter

Indoor side

Outdoor side

Turn to

tighten

Putty

[Drain hose changing procedures]

1. Remove the drain hose. 2. Remove the drain cap.

○Remove it with hand or pliers.○Remove the screw and drain hose,

making it rotate.

.eso

hnia

r

dehttc

ennoC

.4

.

pacnia

r

deht

t

resnI

.3

○Insert the drain cap which was removed

at procedure “2” securely using a

hexagonal wrench etc.

Note: Be careful that If it is not inserted

securely, water leakage may occur.

○Insert the drain hose securely, making

rotate. And install the screw.

Note: Be careful that If it is not inserted

securely, water leakage may

occur.

●

How to remove the indoor unit from the installation board

The marked portion of the indoor

unit base lower latch

①Push up at the marked portion of

the indoor unit base lower latch,

and slightly pull it toward you.

(both right and left hand sides)

(The indoor unit base lower latch

can be removed from the

installation board)

②Push up the indoor unit upward.

So the indoor unit will be removed

from the installation board.

Piping is possible in the rear, left, left rear,

left downward, right or downward direction.

○P

our water to the drain pan located under the heat exchanger,

and ensure that the water is discharged outdoor.

○When the extended drain hose is indoor, securely insulate it

with a heat insulator available in the market.

○Arrange the drain hose in a downward angle.

○Avoid the following drain piping.

Go through all installation steps and check if the drainage is

all right. Otherwise, water leak may occur.

CAUTION

Clearance

○Remove the flared nuts.

(on both liquid and gas sides)

○Remove the flared nuts.

(on both liquid and gas sides)

○Install the removed flared nuts to the pipes to be connected,

then flare the pipes.

roodt

u

OroodnI

Press

Remove

Press

Remove

A

90±0.5°

Dimension A

Liquid side : 9.1

Gas side Model SRK25/35,

DXK09/12 : 13.2

Model SRK45,

DXK15 : 16.6

CONNECTION OF REFRIGERANT PIPINGS

Keep the openings of the pipes covered with tapes etc. to prevent dust, sand, etc. from entering them.

(Do not turn)

○Connect the pipes on both liquid and gas sides.

○Tighten the nuts to the following torque.

Liquid side(

φ

6.35) : 14.0 ~ 18.0 N・m (1.4~1.8 kgf

・m)

Gas side (

φ

9.52) : 34.0 ~ 42.0 N・m (3.4~4.2 kgf

・m)

(

φ

12.7) : 49.0 ~ 61.0 N・m (4.9~6.1 kgf

・m)

Indoor

Liquid side

Gas side

Outdoor

Liquid side

Gas side

(Do not turn)

INSTALLATION OF THE OUTDOOR UNIT

The power supply voltage is correct as the rating.

No gas leaks from the joints of the operation valve.

Pow

er cables and crossover wires are securely fixed

to the terminal board.

Operation valve is fully open.

The pipe joints for indoor and outdoor pipes have been insulated.

The screw of the lid is tightened securely.

The screw of the service panel is tightened securely.

Use a flare tool designed for R410A or a conventional flare

tool. Please note that measurement B (protrusion from the

flaring block) will vary depending on the type of a flare tool in

use. If a conventional flare tool is used, please use a copper

pipe gauge or a similar instrument to check protrusion so

that you can keep measurement B to a correct value.

Copper pipe

diameter

Clutch type flare tool

for R410A

Conventional (R22) flare tool

Clutch type Wing nut type

Measurement B (mm)

6.35

9.52

12.7

0.0~ 0.5

0.0~ 0.5

0.0~ 0.5

1.0~ 1.5

1.0~ 1.5

1.0~ 1.5

1.5~ 2.0

1.5~ 2.0

2.0~ 2.5

Measurement B

Flaring block

Copper pipe

Connection

Preparation

Drain piping work

Fixing of outdoor

● Flaring work

○Make sure that the unit is stable in installation.

Fix the unit to stable base.

○When installing the unit at a higher place or where

it could be toppled by strong winds, secure the unit

firmly with foundation bolts, wire, etc.

○Execute drain piping by using a drain elbow and drain grommets supplied

separately as accessories, where water drained from the outdoor unit is a

problem.

○Water may drip where there is a larger amount of drain water. Seal around

the drain elbow and drain grommets with putty or adequate caulking

material.

○Condensed water may flow out from vicinity of operation valve or

connected pipes.

○Where you are likely to have several days of sub-zero temperatures in a

row, do not use a drain elbow and drain grommets. (There is a risk of

drain water freezing inside and blocking the drain.)

Electric wiring work

○Perform wiring, making wire terminal numbers

conform to terminal numbers of indoor unit terminal

block.

○Connect using ground screw located near mark.

Do not apply excess torque to the flared nuts.

Otherwise, the flared nuts may crack depending on the

conditions and refrigerant leak may occur.

CAUTION

Do not apply refrigerating machine oil to the flared surface.

CAUTION

Air purge

Insulation of the connection portion

Finishing work and fixing

①Tighten all flare nuts in the pipings both indoor and

outside wall so as not to cause leak.

②Connect operation valve, charge hose, manifold valve

and vacuum pump as is illustrated right.

③Open manifold valve handle Lo to its full width, and

perform vacuum or evacuation.

Continue the vacuum or evacuation operation for 15

minutes or more and check to see that the vacuum

gauge reads -0.1MPa.

④After completing vacuum operation, close the Lo

handle and stop operation of the vacuum pump.

⑤

After completing vacuum operation, fully open

operation valve (Both gas and liquid sides) with

hexagon headed wrench.

⑥

Check for possible leakage of gas in the connection

parts of both indoor and outdoor.

●Since the system uses check joints differing in diameter from those found on the conventional models, a charge hose

(for R22) presently in use is not applicable. Please use one designed specifically for R410A.

●Please use an anti-reverse flow type vacuum pump adapter so as to prevent vacuum pump oil from running back

into the system. Oil running back into an air-conditioning system may cause the refrigerant cycle to break down.

Cover the exterior portion

with outer tape and shape

the piping so it will match

the contours of the route

that the piping to take.

Also fix the wiring and

pipings to the wall with

clamps.

Refrigerant piping

Connection wiring,

Earth wiring

Outer tape

Clamp

Wood screw

Drain hose

Cover the coupling with insulator and then cover it with

tape.

Vinyl tape

Place the slit

upward.

(three-way valve)

Charge hose (Designed specifically for R410A)

Compound pressure gauge

Pressure gauge

Gauge manifold

(Designed specifically for R410A)

Handle Hi

Vacuum pump

Vacuum pump adapter

(Anti-reverse flow type)

(Designed specifically for R410A)

Charge hose

(Designed specifically for R410A)

Check joint

-0.1MPa

(-76cmHg)

Handle Lo

Operation valve

Operation valve

(two-way valve)

Operation valve

cap

Operation valve

cap

Operation valve cap

tightening torque (N·m)

Check joint blind nut

tightening torque ( )

φ6.35 (1/4")

φ 01

)

"8/3(

2

5.9 〜12

φ12.7 (1/2") 25〜35

20

〜30

Operation valve size

(mm)

Securely tighten the operation valve cap and the check joint blind nut after adjustment.

○When condensed water needs to be led to a drain, etc., install the unit on

a flat base (supplied separately as an option part) or concrete blocks.

Then, please secure space for the drain elbow and the drain hose.

INSTALLATION TEST CHECK POINTS

After installation

Check the following points again after completion of the installation, and before turning on the power. Conduct a test run again and ensure that the unit operates properly.

At the same time, explain to the customer how to use the unit and how to take care of the unit following the instruction manual.

Test run

Air conditioning operation is normal.

No abnormal noise.

Water drains smoothly.

Protective functions are not working.

The remote control is normal.

(Three-minute restart preventive timer)

When the air conditioner is restarted or when changing the

operation, the unit will not start operating for approximately

3 minutes. This is to protect the unit and it is not a malfunction.

Operation of the unit has been explained to the customer.

(

Unit : mm

)

⑧ Drain elbow

⑦ Grommet

Drain hose

(To be procured on the installer’s part)

Do not put a grommet on this hole.

This is a supplementary drain hole

to discharge drain water, when a

large quantity of it is gathered.

CAUTION

Interconnecting and

grounding wires

(minimum)

SRK25 / DXK09

SRK35 / DXK12

SRK45 / DXK15

Switch breaker

Over current protector

rated capacity

Power source

(minimum)

Model

15A, 30mA,

0.1sec or less

30A 16A 2.0mm

2

1.5mm

2

X 4

Earth leakage

breaker

Phase

Single

-phase

○Always perform grounding system installation work with the power cord unplugged.

○Connect a pair bearing a common terminal number with an indoor-outdoor connecting wire.

○

In cabling, fasten cables securely with cable clamps so that no external force may work on terminal connections.

○Grounding terminals are provided in the control box.

Always use an earth leakage circuit breaker designed for inverter circuits

to prevent a faulty operation.

○The specifications shown in the above table are for units without heaters. For units with heaters, refer to the

installation instructions or the construction instructions of the indoor unit.

○Switchgear or Circuit breaker capacity which is calculated from MAX. over current should be chosen along the

regulations in each country.

○The cable specifications are based on the assumption that a metal or plastic conduit is used with no more than

three cables contained in a conduit and a voltage drop is 2%. For an installation falling outside of these conditions,

please follow the internal cabling regulations. Adapt it to the regulation in effect in each country.

Switchgear or Circuit Breaker

CAUTION

power cable, indoor - outdoor connecting wire circuit diagram

Indoor - Outdoor

connecting wire

Please connect the

earthed line of indoor

and outdoor connect-

ing wire to a bracket

part of the illustration.

CAUTION

Power cable

INSTALLATION SPACE (INDOOR UNIT) (FRONT VIEW)

(

Unit : mm

)

Piping for Liquid Model SRK25~45, DXK09~15 :

ø

6.35

Piping for Gas Model SRK25/35, DXK09/12 :

ø

9.52

Model SRK45, DXK15 :

ø

12.7

190 40.1

47

130.5 508 130.5

157 455

157

187.5

394

187.5

47

7.6247.56.9

65

Space

50

service

100

55

Piping for Gas 359.5

Piping for Liquid 427.5

Drain hose 530 (ø16)

55

Installation board

indoor unitSpace for

service

Space for

for service

15 Space

for service

Piping hole (ø65)

Piping hole (ø65)

Preparation of indoor unit

Mounting of connecting wires

① Remove the lid.

②

Remove the terminal cover.

③ Remove the wiring clamp.

④ Connect the connecting wire securely to the terminal block.

1) Connect the connection wire securely to the terminal block. If

the wire is not affixed completely, contact will be poor, and it is

dangerous as the terminal block may heat up and catch fire.

2) Take care not to confuse the terminal numbers for indoor and

outdoor connections.

⑤ Fix the connecting wire by wiring clamp.

⑥ Attach the terminal cover.

⑦ Attach the lid.

Use cables for interconnection wiring to avoid loosening of the

wires. CENELEC code for cables Required field cables.

In case of faulty wiring connection, the indoor unit stops,

and then the run lamp turns on and the timer lamp blinks.

H

05

R

N

R

4

or

5

G

1.5

H05RNR4G1.5 (Example) or 245ICE57

Harmonized cable type

300/500 volts

Natural-and/or synch. rubber wire insulation

Polychloroprene rubber conductors insulation

Stranded core

Number of conductors

One conductor of the cable is the earth conductor

(yellow/green)

Section of copper wire (mm

2

)

CAUTION

Loading...

Loading...