LP-205-Q Rev. 5/14/08

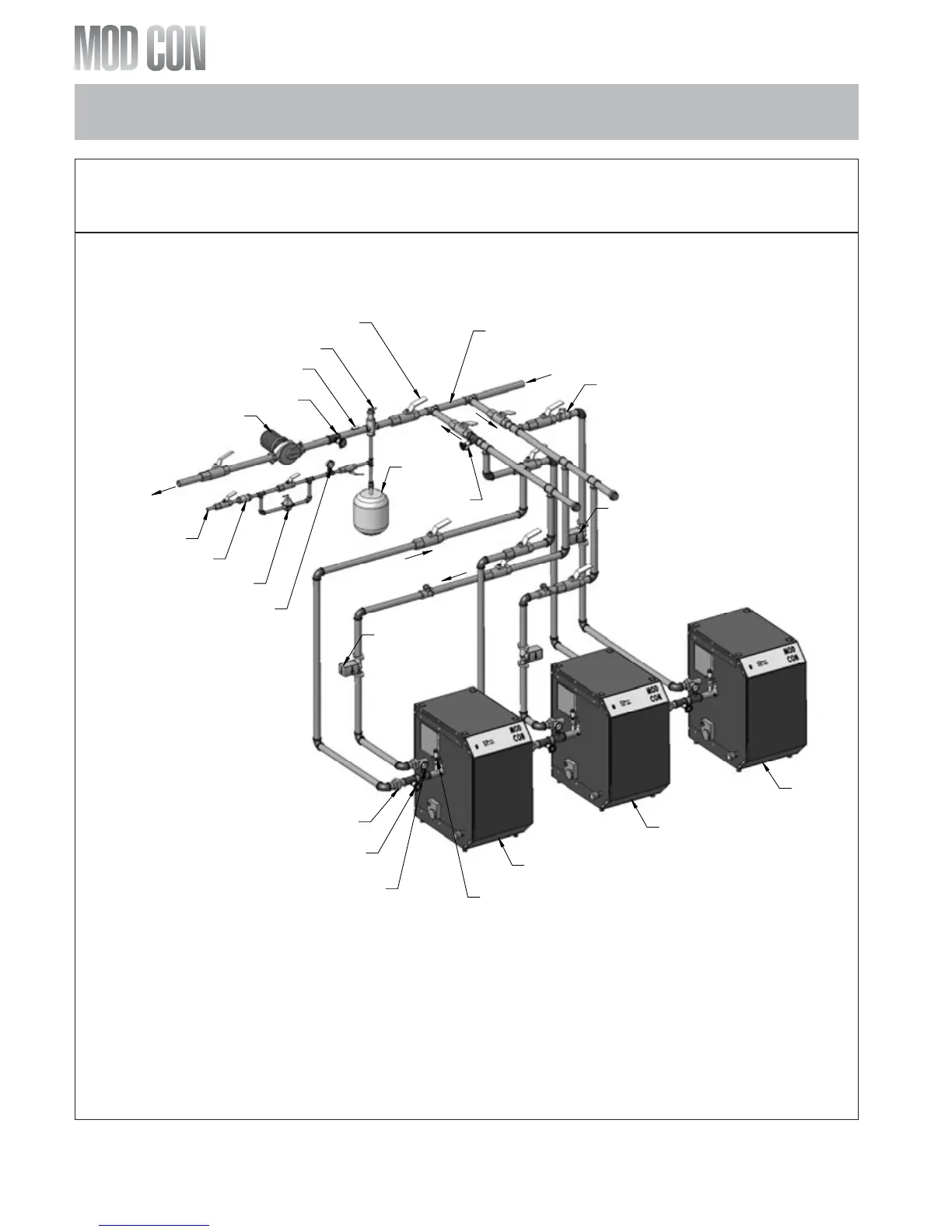

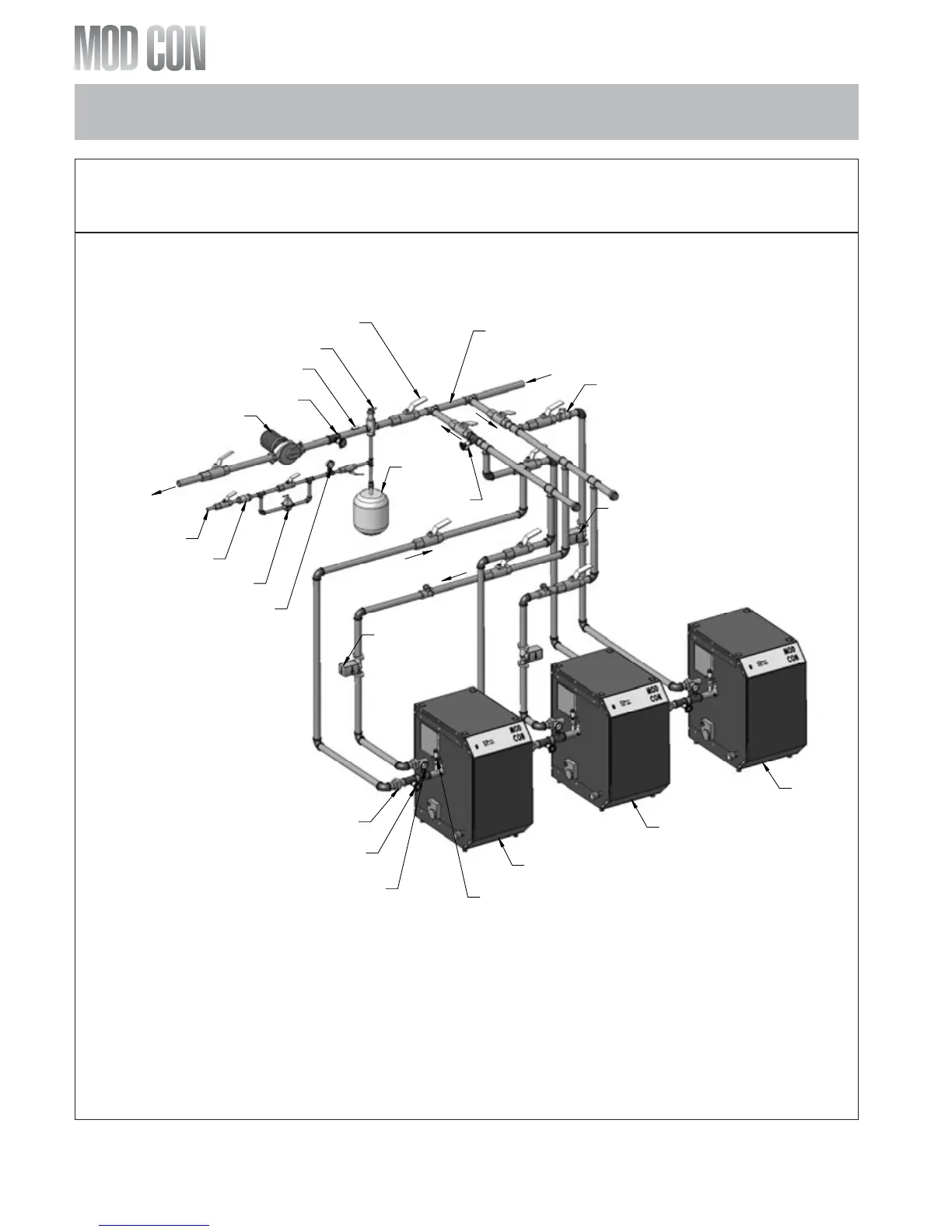

PART 5: BOILER PIPING (CONTINUED)

NOTES:

1. This drawing is meant to show system piping concept only.

2. An Anti-Scald mixing valve is recommended if the DHW temperature is set above the factory setting

of 119°F.

3. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

6. System Flow (Secondary Loop) must be greater than the boiler’s primary loop flow.

GAS-FIRED BOILER Boiler Manual

19

Loading...

Loading...