54

GAS-FIRED BOILER Boiler Manual

Function Value

d6 — Actual Fan speed multiplied by 10

(Example: If fan speed displayed is

|410| RPM x 10 = 4100 actual fan speed)

d7 — Actual Ionization current read from

Flame Rectification probe

d8 — Actual Status of the Central Heating

Circulator Off = |0|, On = |1|.

d9 — Actual Status of the Indirect Fired

Circulator Off = |0|, On = |1|.

d10 — Actual Status bus communication

|CO| = connected, |NO| = not connected

d11 — Central Heating Set Point

d12 — Power On Hours in thousands (display

will not read until 100 hrs.)

Example: Display x 1000 = Power on

Hours

12.3 x 1000 = 12300 Hours)

d13 — Total Central Heat Hours in Thousands

(display will not read until 100 hrs)

Example: Display x 1000 = Power on

Hours

12.3 x 1000 = 12300 Hours

d14 — Total Domestic Hot Water Hours in

Thousands (display will not read until

100 hrs)

Example: Display x 1000 = Power on

Hours

12.3 x 1000 = 12300 Hours

d15 — Passed Ignition Attempts in Thousands

(display will not read until 100 ignition

attempts)

Example: Display x 1000 = Power on

Hours

12.3 x 1000 = 12300 ignition attempts

d16 — This function only becomes active

when the Boiler is set as the Master. It

allows the user to monitor the System

Pump connected to the Master Boiler

and the connected boilers (Followers)

in a multiple boiler installation. Each

boiler firing output percent is

displayed. To toggle between values

press the {S1/

-

} to go down and the

{S4/RESET} key to go up. The first

function you will see is

System Pump - 0 off or 1 on

Master Boiler - P0 alternating (0-100 Percentage

firing rate)

Follower Boiler #1 – P1 alternating (0-100

Percentage firing rate)

Follower Boiler #2 – P2 alternating (0-100

Percentage firing rate)

Follower Boiler #3 – P3 alternating (0-100

Percentage firing rate)

Follower Boiler #4 – P4 alternating (0-100

Percentage firing rate)

Follower Boiler #5 – P5 alternating (0-100

Percentage firing rate)

Follower Boiler #6 – P6 alternating (0-100

Percentage firing rate)

Follower Boiler #7 – P7 alternating (0-100

Percentage firing rate

NOTE: If you toggle beyond parameters of con-

nected boilers, the display will go into the next

function value.

D. TEST MODE

This function is intended to simplify the gas valve

adjustment if needed. Listed below are the rec-

ommended limits on each Mod Con Boiler and the

Combustion Settings. Automatic modulation does

not take place when the controller is in Test mode,

only temperature limitation based on the Mod Con

Boiler Central Heating set point. The user will be

allowed to increase or decrease the fan speed by

pressing in either the {S1/

-

} or {S2/+} keys.

To activate the Test mode simply press the {S2/+}

and {S3/Program} key together for 1 second. Once

activated, you will see in the display {Ser} and the

actual fan speed. The measurement of the com-

bustion levels should always be taken at the high-

est and lowest fan speed. After 20 minutes, the

Test mode stops automatically. To exit Test Mode

press {S1/

-

} and {S2/+} key together for 1 second.

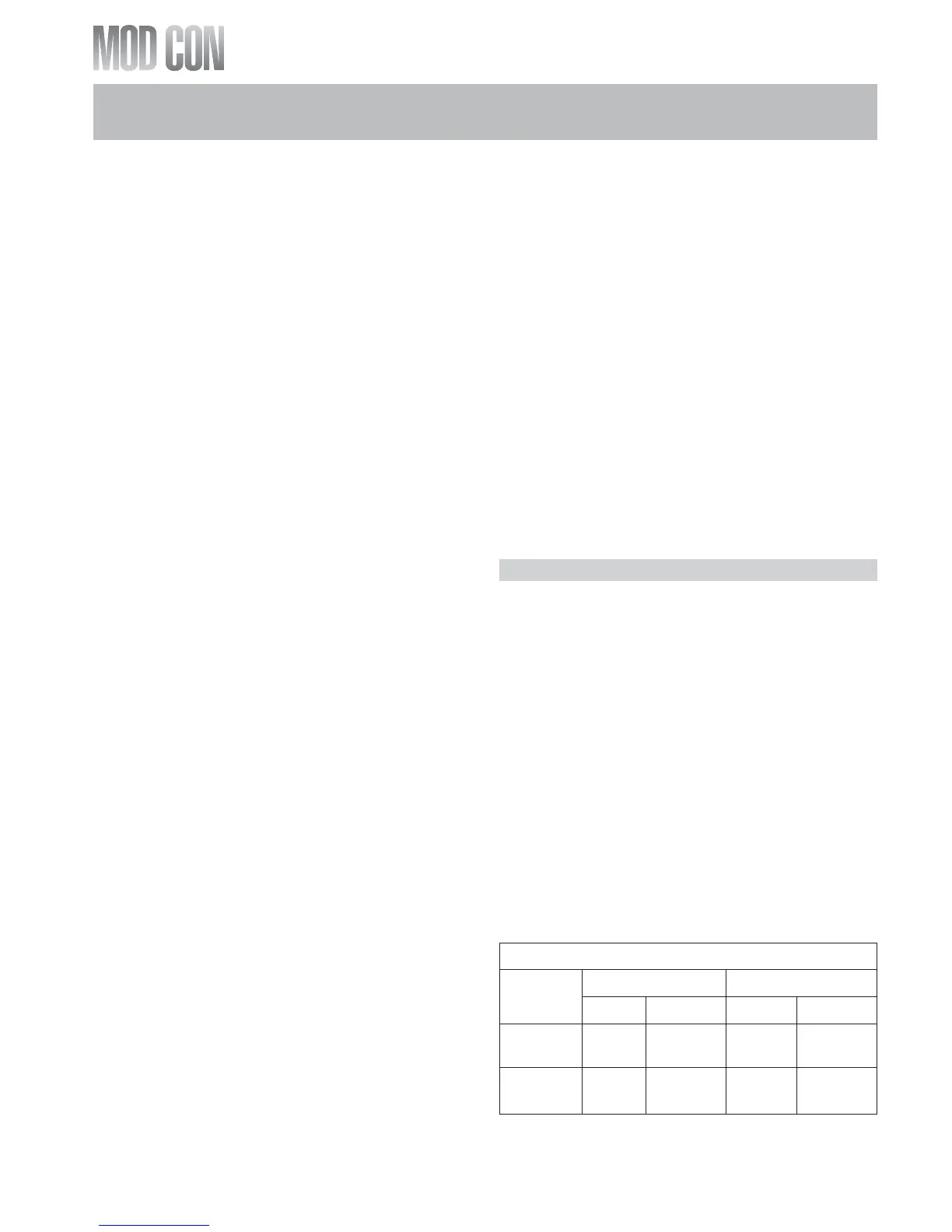

PART 10. START-UP PROCEDURE (CONTINUED)

COMBUSTION SETTINGS ON ALL MODELS

Natural Gas Propane LP

low high low high

Carbon Monoxide

(CO %)

0–20 ppm 70 ppm–135 ppm 0–20 ppm 80 ppm–150 ppm

Carbon Dioxide

(CO

2

%)

8½% – 9½% 8½% – 9½% 9½% – 10½% 9½% – 10½%

Fig. 10-1

Loading...

Loading...