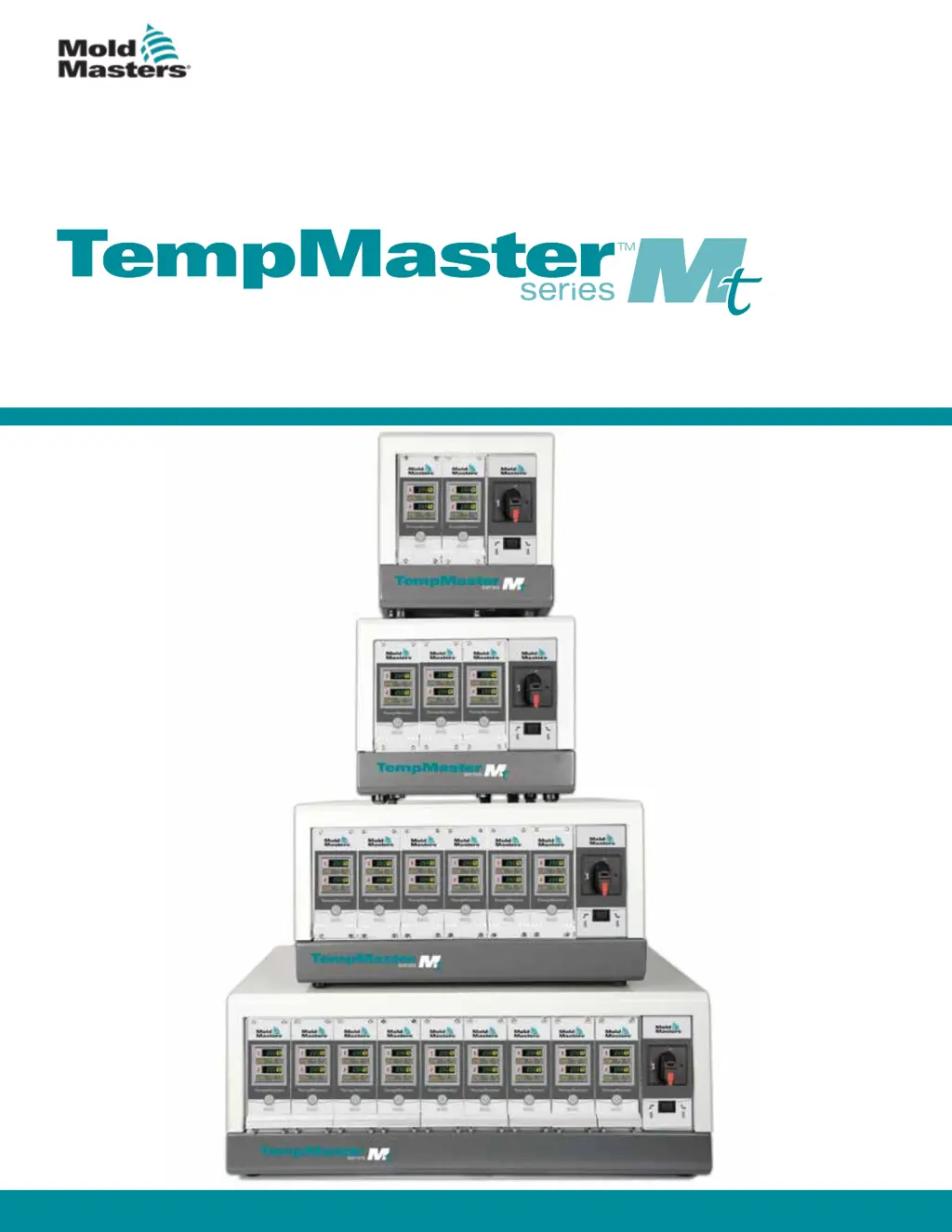

What to do if the output fuse for a zone fails in my Mold-Masters TempMaster MT-04-04 Temperature Controller?

- SStephanie PetersJul 25, 2025

If the output fuse fails, it indicates a fault external to the controller. Replace the fuse with one of the same rating and type, specifically a High Rupture Current load fuse. The fuse is located on the control card.